Planer exact 63

24" planing width meets every requirement!

Whether it‘s in a carpenter‘s workshop, in workshops where solid wood is machined or in the field of modern cabinet-making – the performance of the Format-4 planer exact 63 is astounding. Maximum performance, easy operation and individual machine options available at a competitive investment price, guarantee perfect planing results for even the most demanding tasks.

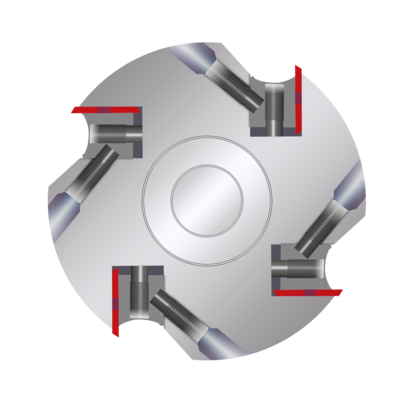

4 different cutterblock systems to choose between:

- 4 knife Format System cutter-block

- 4 knife Standard cutter-block using traditional single sided planer knives

- 4 knife TERSA cutter-block

- Silent-Power® spiral cutter-block

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

... FORMAT4 Premium machines for premium requirements

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Tailor made financing solutions

Details

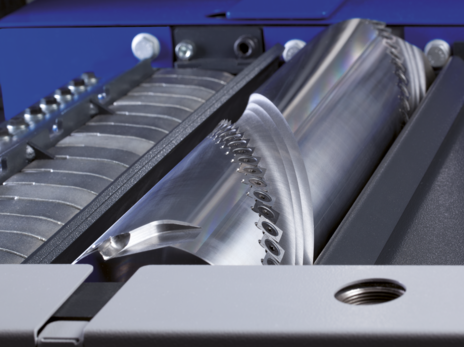

The planer with the Format4 System cutterblock, 120 mm knife flight and 4 knives delivers performance, precision and user-friendliness all-in-one.

Exclusive for planer/thicknessers from the Felder Group. The Silent-Power® spiral cutterblock reduces noise emissions by more than half when planing. The continuous pulling cut ensures tear-free results when planing all types of wood. With this revolutionary new development from Format4 you are obtaining all of the advantages of a spiral cutterblock at considerably lower operating, investment and adjustment costs. The advantages of the Silent-Power® cutterblock at a glance ...

- Extremely quiet, noise is reduced by half

- Usable blade life twenty times longer than standard blades

- Four highly precise cutting edges on each knife

- Optimised chip extraction and reduced chip volume

- Tear-free jointing results

- Reduced power consumption when compared to similar systems

Technical data

Electrics

Cutterblock

Thicknesser and Feed Drive

Important Accessories

General

Packaging

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP USA Headquarters Details

USA Headquarters | New Castle, Delaware Showroom

2 Lukens Drive, Suite 100-400

New Castle, DE 19720

Tel.: 866-792-5288

Fax: 302-322-9865

Business Hours: Mo. – Fr. | 8am – 5pm (EST)

FELDER GROUP USA Dallas Details

South Division | Dallas, Texas Showroom

1420 Halsey Way / Suite 100

Carrollton, TX 75007

Tel.: 866-792-5288

Business Hours: Mo. – Fr. | 8am – 5pm (CST)

FELDER GROUP USA West Sacramento Details

West Division | West Sacramento, California Showroom

1747 Enterprise Blvd.

West Sacramento, CA 95691

Tel.: 866-792-5288

Fax: 916-375-3194

Business Hours: Mo. – Fr. | 8am – 5pm (PST)

FELDER GROUP USA Anaheim Details

West Division | Anaheim, California Showroom

3531 E. Miraloma Ave., Unit 1

Anaheim, CA 92806

Tel.: 866-792-5288

Business Hours: Mo. – Fr. | 8am – 5pm (PST)

FELDER GROUP USA Denver Details

West Division | Denver, Colorado

Tel.: 866-792-5288

Business Hours: On appointment