Vlak-vandikteschaafmachine Hammer A2-26

- Vlakschaafbreedte: 260 mm

- Lengte van de vlakschaaftafel: 1045 mm

- Schaafas zelfinstellende schaafmessen

- Max. spaanafname: 3 mm

- Vandiktehoogte 3–184 mm

- Aanvoersnelheid 4,5 m/min

excl. BTW , excl. verzendkosten

incl. 21% BTW , excl. verzendkosten

Omschrijving

A2 – de nieuwe "kleine" vlak-/vandikteschaafmachine voor kwaliteit en precisie in kleine werkplaatsen

Niet alleen met de comfortabele afmeting voor kleine werkplaatsen overtuigt de nieuwe A2-26, zeker ook door de tientallen jaren ervaring met Hammer-schaafmachine-benchmarks.

Details

De 3-messen-automatic-schaafas van Hammer garandeert uitstekend geschaafde houtoppervlakken en maximaal bedieningscomfort. Sinds 1987 zorgen we er met het schaafassysteem met omkeerbare messen voor dat onze duizenden klanten wereldwijd geen extra geld voor traditionele strookschaafmesassen moeten uitgeven. Het schaafassysteem met omkeerbare messen krijgt u exclusief in de schaafmachines van Felder.

De sterk geribde Hammer vlak- en vandikteschaafmachines zijn van massief machinegietijzer en zorgen voor buitengewone precisie in elke situatie. De breedte van de vlakschaaftafels komt telkens met de schaafbreedte overeen. Op die manier worden werkstukken bij het vlakschaven over de volledige lenge van de vlakschaaftafel veilig geleid.

De spaanafname wordt met een draai-hendel aan de achterzijde van de machine ingesteld! Dit levert voor de beidener een snelle en preciese instelling van de spaanafname op met maximaal bediencomfort. Max. spaanafname: 3 mm

De zwenking van de schaafaanslag van 90°–45° is heel eenvoudig door 2 knevels te lossen. En bovendien profiteert de gebruiker van een bijzonder groot aangebracht skala. 2 eindaanslagen bij 90° en 45° zorgen voor precisie, tijdbesparing en bediencomfort.

Optimale plaatsbesparende en ergonomische oplossing: de naar achteren opgeklapte vlakschaaftafels maken een plaatsbesparende opstelling van uw Hammer schaafmachine mogelijk. Bovendien garanderen ze een ergonomisch juiste workflow bij het vandikteschaven.

De afzuigtechnisch geoptimaliseerde spaanderafzuigkap zorgt met groot gehouden spaanruimtes voor een ideale afvoer van spaanders en schone werktafels.

De maximale vandiktehoogte bedraagt 184 mm. De aflezing van de vandiktehoogte vindt plaats via een royaal gedimensioneerd skala aan het machinechassis. Een nog preciezere, tot op een tiende van een millimeter nauwkeurige instelling van de vandiktehoogte is mogelijk met het systeemhandwiel en de geïntegreerde digitale klok.

Technische gegevens

| Frequentie [Hz] | 50 |

| Spaanderafname max. [mm] | 3 |

| Spanning [V] | 1x 230 |

| Vermogen (HP) | 2,6 |

| Vermogen [kW] | 1,9 |

| Vlakschaaftafellengte [mm] | 1045 |

Passende artikelen

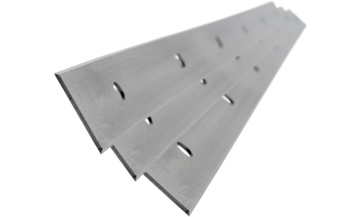

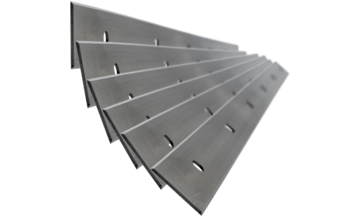

HS-M42 systeemschaafblad

500-07-011 | voor Felder / Hammer | Lengte 260 mm

Schaafmessen voor FELDER, HAMMER en Format 4 systeem schaafas

Lees verderexcl. BTW , excl. verzendkosten

incl. 21% BTW , excl. verzendkosten

Aluminium systeem handwiel

12.1.311 | Ø 160 mm

Systeemhandwiel van hoge kwaliteit voor hoekverstelling op Felder en Hammer machines

Lees verderexcl. BTW , excl. verzendkosten

incl. 21% BTW , excl. verzendkosten

Klok met digitale weergave

01.1.202 | voor vandiktehoogte indicatie, boorhoogte Felder FD 250 | weergave in mm

Precieze digitale klok voor montage op systeemhandwielen

Lees verderexcl. BTW , excl. verzendkosten

incl. 21% BTW , excl. verzendkosten

Rij-inrichting voor Hammer Serie 3 | zonder hefarm

503-134 | voor Hammer A2 26, A3 26, A3 41 (vanaf bouwjaar 09/2011), B3 basic, B3 winner, B3 perform, K3 basic, K3 winner, F3

Rij-inrichting voor het comfortabel verplaatsen van Hammer machines

Lees verderexcl. BTW , excl. verzendkosten

incl. 21% BTW , excl. verzendkosten

Hefarm voor Hammer machines

500-149

Hefarm voor snelle en eenvoudige verplaatsing van Hammer machines

Lees verderexcl. BTW , excl. verzendkosten

incl. 21% BTW , excl. verzendkosten

Systeemschaafmessen |

500-07-010 | voor Felder Hammer | Lengte 260 mm

Schaafmessen voor FELDER, HAMMER en Format 4 systeem schaafas

Lees verderexcl. BTW , excl. verzendkosten

incl. 21% BTW , excl. verzendkosten

Dit zou u ook kunnen interesseren

Hefarm voor Hammer machines

500-149

Hefarm voor snelle en eenvoudige verplaatsing van Hammer machines

Lees verderexcl. BTW , excl. verzendkosten

incl. 21% BTW , excl. verzendkosten

FAQs

Planers are used to produce flat and smooth wood surfaces. There is a distinction between surface planers and thickness planers or the combination of these two machines, the so-called planer-thicknesser. Before a "rough" board of solid wood or plastic can be cut to the desired thickness, the surface planer is used to produce a flat and smooth surface on one side and a flat and smooth surface at a 90-degree angle to it on the narrow side. Subsequently, the facing, unprocessed surface can be planed to the desired thickness with the thicknesser. The result is an entirely smooth and, above all, dimensionally and angularly accurate workpiece - a guarantee for the success of all subsequent machining or application processes.

The frictional resistance between the machine table and the wood is reduced with special lubricants developed for woodworking. Especially when working with resin-rich solid woods, the use of lubricants in woodworking is inevitable. Liquid lubricants are best suited and their application onto the machine table via a spray bottle is very simple and easy. When using lubricants, it is important to ensure that they are fully volatilised after processing to prevent any negative effects on subsequent surface treatments with stains and lacquers. hier you can find Supergleit - the best choice for planing, but also as a lubricant for circular saw and moulding operations.

The purchase price of a planer depends on several factors - the type of machine, planing width, scope of performance and functions, the degree of automation or other desired features. Well thought out from the start, a perhaps higher purchase price pays off in the long run compared to a purely price-based purchase. Additional costs for high technology and work safety, which are incorporated as key components in planers, maintain their value over the years and even decades. One example: the Silent-Power® spiral cutterblock from Felder with spiral blade technology is many times quieter than other cutterblocks, protecting your ears and increasing work safety. The Silent-Power® spiral cutterblock also uses carbide reversible blades with 4-fold cutting edges - which increases the tool life by up to 20 times compared to HSS or SS cutting materials. The Silent-Power® spiral cutterblock therefore scores across the board and saves you money at the same time. Scroll up for a wide selection of planer/thicknessers in every price and performance range.

In many European countries, regulations require the sole use of clean-air extraction units in commercial establishments. Clean-air dust extractors reduce the dust load in the ambient air to 0.1 mg/m3 residual dust content. Of course, from the point of view of work safety and health, clean-air dust extractors are always a good choice - even beyond legal regulations. When choosing an air filter dust extractor, the dust load of the air in the workshop can also be reduced with so-called cartridge filters. The following applies to both clean-air and air filter dust extractors: The air speed at the machine-side extraction connection must be between 18 m/s and 22 m/s; 28 m/s for the continuous processing of predominantly wet wood. Extraction capacity calculations, which calculate both the cross-section of the necessary pipes or hoses and the required power of the extraction unit or system on the basis of the number of machines and the distance to be extracted, provide one hundred percent certainty for perfect extraction results. Of course, when extracting dust from a planer, the width of the cutterblock and the maximum possible chip removal must also be taken into account. These two values determine the expected volume of chips removed through the dust extraction hose or pipe system via the dust extractor system or unit. If the chip bags or containers are too small, the cycles for emptying them will increase considerably. hier you can discover our large selection of dust extractors and filters.

Stationary planer-thicknessers are used for flush planing and levelling of solid wood. As a first step, the wood is planed. The workpiece is fed to the rotating cutterhead through the infeed surface planer table. The alignment of the infeed planer table is parallel to that of the cutting circle of the cutterblock. This distance between the planer table and the cutting circle is responsible for the chip removal and is usually adjustable; depending on the design, the chip removal can vary by up to several millimetres. After feeding the workpiece to the cutterblock and after chip removal, the workpiece passes over the outfeed planer table. The outfeed planer table and the cutting circle of the cutterblock are in parallel alignment, i.e. the cutterblock and the outfeed planer table are at the same level. The result is an aligned, flat and smooth wood surface. This process is called "planing", the corresponding machine is called "surface planer". The side opposite to the planed wood surface can now be planed to the desired thickness in a second work step. This operation is called "thicknessing" and the machine required for this is the "thicknesser". Thicknessers have a thicknessing table that can be adjusted to size in height. A feed roller, usually grooved or toothed, located in front of the cutterblock ensures that the workpiece is fed safely to the cutterblock. The cutting circle of the cutterblock corresponds to the set thicknessing table position, the chip removal rate possible in each case can be up to several millimetres. Behind the cutterblock is a smooth outfeed roller that gently transports the thickness-planed workpiece away from the cutterblock. Depending on the application, surface planers are used as stand-alone machines or as combined surface and thickness planers. hier you can see the chip flight during planing work in super slow motion.

Generally, the main criteria for buying a planer is the intended area of use, a defined amount of space, ease of use and sustainability in terms of the cost of planer knives. A quick commercial answer is the intended area of use, planing, thicknessing or both in one, with a defined amount of use per day, per month or per year. The higher the expected workload, the higher the quality and stability required of a new planer/thicknesser. In terms of space, the mere machine footprint should not be considered the sole criterion; some planers require additional, valuable floor space due to their design - e.g. for protruding fences behind the machine. In any case, a very good alternative where space is limited are planer-thicknessers. Ease of operation comprises decision criteria such as set-up and changeover times, the latter especially in the case of planer-thicknessers. While the adjustment of planing or thicknessing tables is mainly done manually on smaller planers, electrical adjustment options with LED displays up to programmable positioning and roughing finishing allowances are mostly standard on larger planer-thicknessers. For decades, various manufacturers have been producing flawless, sustainable sets of planing knives using reversible knife technologies. Nevertheless, there are groundbreaking developments that are becoming more and more popular on the market, such as the Silent-Power® sprial cutterblock from Felder that reduces noise by half, equipped with carbide reversible cutting edges and 4 cutting chamfers per cutting edge. The tool life of carbide is 20 times higher than that of HSS or SS cutting materials. The Silent-Power spiral cutterblock therefore scores across the board and saves you money at the same time. You can find a wide selection of high-quality planer/thicknessers for many applications further up on this page.