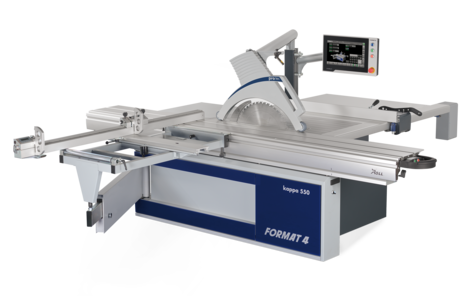

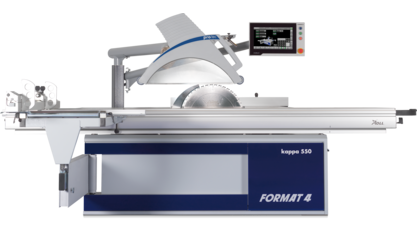

Sliding table saw kappa 550 e-motion

Powerful. Smart. Safe. The new edition of the successful top model sliding table panel saw

Design, precision, automation and safety put in a nutshell in the smartest of ways. For more than a decade, the kappa 550 has been the first choice for sliding table panel saws and in its new edition it continues to be right at the cutting edge. Individual specifications, an intelligent operating concept and numerous new impressive Format4 features ensure maximum efficiency and a noticeable increase in productivity.

The e-motion features of the Format4 kappa 550 impress with an automatic rip fence, unlimited tool storage and programmable cutting sequences in the smart, in-house software. All axes of the machine can be controlled ergonomically and intuitively by the central operating unit with 15 "touch screen.

The Format4 premium sliding table panel saw kappa 550 is also the world's first sliding table saw with the revolutionary PCS® safety system.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

Variants

Models- Your benefits

... FORMAT4 Premium machines for premium requirements

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Tailor made financing solutions

- 67 years of mechanical engineering experience

Details

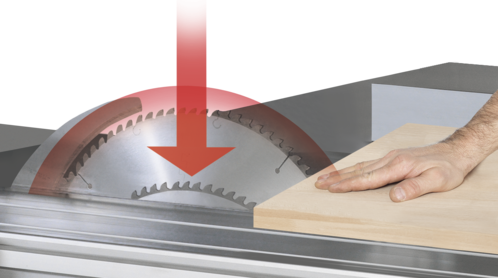

Serious accidents on the sliding table panel saws are a thing of the past - PCS® is currently the fastest non-contact triggering safety device, worldwide.

- PCS detects accident hazards before contact with the saw blade.

- PCS eliminates the hazardous situation in milliseconds.

- PCS is 100% safe against damage to machine and saw blade.

- PCS allows safe operation close to the saw blade.

- PCS supports groove cuts.

- PCS is ready to be used again at the push of a button.

- PCS requires no additional maintenance and cleaning cycles.

- PCS works without additional external energy sources and without external sensors or video systems.

- PCS is resistant to dust and dirt.

*PCS® does not replace any of the legal protective devices required. The machine must be operated with the splitter and the saw guard properly installed according to regulations.

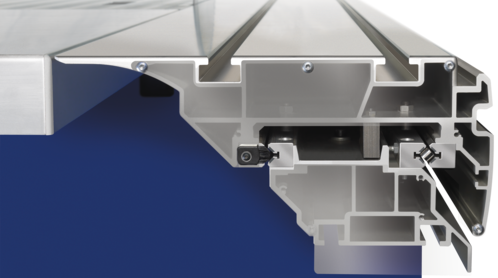

The updated heavy cast-iron Format4 saw assembly offers precision, performance and smooth operation:

- 3-axis “Control” scoring unit

- Scoring unit park position

- Change the saw blade without tools!

- Large cutting depth, even with a scoring unit

- Spraying equipment for the processing of non-ferrous metals and plastics

- Saw unit with “Easy-Glide” tilt segment guiding system

- Tilting of saw-blade 0°-46°

- Oversized saw arbor with double bearing trunnions

- Absolute vibration-free machining

- Incredible power transmission due to the ultra efficient Poly-V-belt drive technology

- Precise double trunnion system

- High load-bearing capacity and operating life

- Play free tilt

- Unaffected by dust

- Completely maintenance free

- No lubrication required

- 6 year guarantee

With the new kappa 550 you can dramatically increase the cutting height of your panel saw. The kappa 550 gives you 202 mm at 90° and 141 mm at 45°. When you are looking at premium class panel saws, these are the figures you should be searching for!

The kappa 400 has dado capability. Used with the massive specially designed Format4 dado cutter head clean, precise dado cuts from 1/4”–3/4” (6–20 mm) are guaranteed.

Choose between two high performance scoring units: Classic, Automatic Both units combine reliable operating and drive technology for perfect scoring results. That’s guaranteed with a 5 inch diameter scoring blade and a speed of 10300 rpm (60Hz).

An alternative to the worldwide unique Format4 saw blade quick change system "Easy-lock" is now the "Quick-lock" clamping system, which with the use of just one tool makes it quick and easy to change the saw blade.

The rip fence is positioned by a motor and runs via a dust-free integrated ball spindle in the saw table. The 1/10 mm precision, the high positioning speed, as well as the simultaneous positioning of the crosscut fence, saw blade height and saw blade angle ensure precision and save valuable working time.

- Optional with the x-motion

- Standard on the e-motion model

- Standard table scale

- Standard fine adjustment

- Optional electronic digital indicator for the standard rip fence

- Optional position control, rip capacity reading from the electronic digital indicator Easy moving, the rip fence almost hovers over the guide bar on the saw sliding table saw. The single-handed quick clamping and the fine adjustment ensure the quick and accurate setting of the rip fence to your required measurement! The aluminum rip fence plate can be adjusted to optimize the feed of workpieces. When working with narrow and thin cuts of wood or with the sawblade tilted, it can be inverted and used in the lying position.

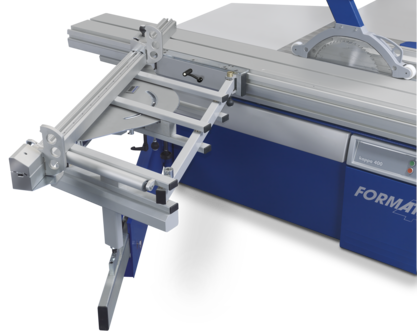

The integrated guide rollers of the outrigger table ensure an incredibly smooth operation upon maximum load capacity. The bearing rail is moved along a “X-Roll” guide and is fast and micro-adjustable. The LED display enables you to set the required angle to one tenth of a degree. The fence can be tilted to any position between -45° and +45° and guarantees precise mitre cuts.

On request, we’ll equip your Format4 with the digital telescopic fence. Below, you see the cleverly integrated electronic digital scale with values correct to 4/1000” (0.1 mm). Additional functions, for example the setting of successive measurements, make your daily working life easier.

The outrigger table can be swung out of the way with ease. You no longer have to worry about the hassle of mounting and dismounting the outrigger table. The swing away system of the outrigger table ensures extreme ease of use and at the same time can provide you with extra working space when you need it.

The FORMAT4 overhead saw guard is integrated nicely into the machine design. It is easy and convenient to use. With only a flick of the wrist the saw guard can be moved and tilted completely away from the machine area. The dust extraction hood adjusts itself automatically to the work piece height and always provides optimal working safety and dust extraction performance.

In the overhead saw guard handle a signal lamp is integrated, which indicates the operating status of the PCS® to the operator.

For the processing of non-ferrous metals, your Format4 can be fitted with spraying equipment. This enables high performance lubricating oil to be sprayed directly onto the sawblade.

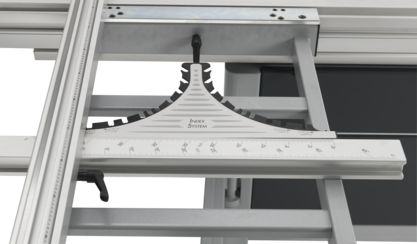

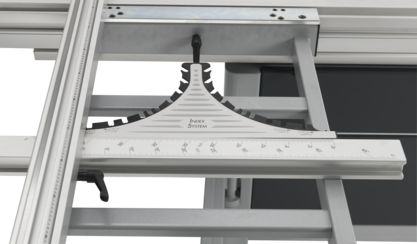

One of the valuable accessories in daily use on woodworking machines is the patented double mitre gauge from Format4. It enables double miter cuts on workpieces of different widths at any angle. The input of the of the workpiece widths A, B and the input of the desired frame angle, is carried out on the integrated computer via the keypad. Das Einstellergebnis erscheint zehntelgradgenau am Display. Just set the double miter gauge at the calculated value and work away with results of … pinpoint accuracy! The fence stop on the fence plates can be adjusted up to 53 inches with the scale. Depending on set angles, the length compensating vernier scale is available. With this you can also set the exact workpiece length when angle cutting.

You now no longer need to remove the scoring unit when using large diameter saw blades. At the touch of a button the new Format4 will park the scoring blade, leaving enough space for a large diameter blade, and in doing so saves valuable production time. Additionally the park position also protects the scoring blade from resin.

No time wasted trying to find the correct angle and one hundred percent precision in adjustment and positioning, without any reading errors, are just some of the advantages of the precision mitre index system. High-precision rest points allow the dimensionally accurate Creation of polygons such as 5.625° (32 corner), 11.25° (16 corner), 22.5° (octagon). Additional rest points at 15°, 20°, 25°, 30°, 35°, 40° and 45° can be selected as well as push and thrust. Each resting point is equipped with a length compensation. The high-precision degree raster index System is set at the factory and each resting point can be individually be fine-tuned. That shapely adapted to the machine design degree grid index system boosts your productivity into a unique price-performance ratio.

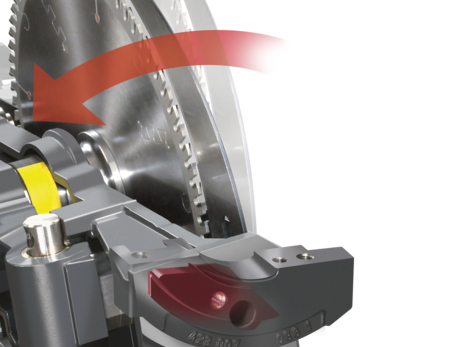

The circular saw unit tilts thanks to the tried-and-tested Format-4 "Easy-Glide" swivel segment guide. The "sliding shoe guides" on the large-sized swivel segments are made of a synthetic, wear-free high-performance material, which is dust-resistant and requires neither maintenance nor lubrication.

The „Easy-Glide“ system comes with a 6-year warranty!

3-axis positioning simultaneously - up to 50% time savings compared to other premium manufacturers

kappa 550 e-motion

All axes of the machine can be controlled ergonomically and intuitively by the central operating unit with 15 "touch screen. The in-house software with graphical user interface, a multitude of programs, a USB interface and the prepared network connection make work easier and guarantee efficiency and maximum productivity. The USB interface for importing and exporting data is prepared for network connection and remote maintenance.

Program memory

- Tool database (incl. scorer Position for 2-axis scorer and scorer control)

- Editing programs in general

- Programs for the respective function

- Memory of the last five input values

- Import and export tool database, program memory

- Remote maintenance via Teamviewer

functions

- Parking position (rip fence, scorer controls)

- Movement of the axes in jog mode

- Incremental method of Axles

- Calculator

- Administrator functions

Cutting programmes / outrigger table functions / crosscut fence:

- Wrong Mitre

- Compound Mitre Cut (except with controlled crosscut fence)

- Processing of the cutting plans of a cutting optimisation software

- Mitre Cut

Cutting programs / functions in conjunction with a controlled rip fence:

- Rebate

- Groove

- Notches

- Bevel Cut

- Diagonal cut plus

(*Position controlled rip fence Option)

Upon request, the "smartouch" machine control system can be extended with numerous other programs for geometric functions: knee bar, parallelogram, trapezoid, polygon, staircase, triangle, pyramid, cuboid, slots / tenon, corner bench rest

Every cut with the Format4 sliding table saw is a masterpiece of precision. For example, when cutting a pyramid, which is one of 18 predefined cutting programs.

Rabbets, grooves, notches, wrong mitre, rafter cut and various geometric shapes, in short videos we show you how it works: Enter workpiece shape and workpiece dimensions on the touch screen, follow the visual cutting plan - done.

View cutting program videos here

*Please note that some of the cutting programmes shown are not possible on machines without double tilt.

Due to the integration of the Format4 cutting optimization system into the machine and operating concept, all phases of processing can be carried out quickly, efficiently and centrally. No training is necessary as the user interface is intuitive, clear and easy to use.

The e-motion models can be equipped with the CNC controlled crosscut fence. The controlled crosscut fence can be used on both sides of the outrigger and is equipped with two fence stops. The maximum adjustable length measures 3400 mm. The extendable component can be removed to save space. The length compensation takes place automatically depending on the set angle.

- Electronic crosscut fence with 2 crosscut stops and extendable to a maximum of 3400 mm

- automatic angle/length compensation

The overhead saw guard can be unlocked with one movement and completely swung away from machine table area. If desired, the overhead saw guard can be unlocked directly via a lever on the hood.

Upon request we can equip your kappa with LED lighting and an integrated tool compartment for 4 saw blades with a diameter of max. 400 mm, 1 saw blade with a diameter of max. 550 mm and 2 splitters.

The convenient parts list holder with A4 clipboard is mounted on the overhead control panel, keeping your parts lists in sight at all times.

kappa 550 x-motion

controls

kappa 550 x-motion: 10" touchscreen*

kappa 550 e-motion: 15" touchscreen

All axes of the machine can be controlled ergonomically and intuitively by the central operating unit with touch screen. The in-house software with graphical user interface, a multitude of programs, a USB interface and the prepared network connection make work easier and guarantee efficiency and maximum productivity. The USB interface for importing and exporting data is prepared for network connection and remote maintenance.

Program memory

- Tool database (incl. scorer Position for 2-axis scorer and scorer control)

- Editing programs in general

- Programs for the respective function

- Memory of the last five input values

- Import and export tool database, program memory

- Remote maintenance via Teamviewer

functions

- Parking position (rip fence, scorer controls)

- Movement of the axes in jog mode

- Incremental method of Axles

- Calculator

- Administrator functions

Cutting programmes / outrigger table functions / crosscut fence:

- Wrong Mitre

- Compound Mitre Cut (except with controlled crosscut fence)

- Processing of the cutting plans of a cutting optimisation software

- Mitre Cut

Cutting programs / functions in conjunction with a controlled rip fence:

- Rebate

- Groove

- Notches

- Bevel Cut

(*Position controlled rip fence Option)

Due to the integration of the Format4 cutting optimization system into the machine and operating concept, all phases of processing can be carried out quickly, efficiently and centrally. No training is necessary as the user interface is intuitive, clear and easy to use.

The rip fence can be fitted with an electronic digital-display. The perfect integration of the electronic unit allows you to turn the display around 90°, so the values are clearly and exactly readable from the operating area. Additional functions such as the input of successive measurements make your daily working life easier. Further highlights:

- Bright, easy to read LED display

- No batteries are required due to a direct connection to the machine's power supply

- Automatic recognition of vertical or horizontal fence position

- Measurement compensation of the saw blade tooth width

The e-motion models can be equipped with the CNC controlled crosscut fence. The controlled crosscut fence can be used on both sides of the outrigger and is equipped with two fence stops. The maximum adjustable length measures 3400 mm. The extendable component can be removed to save space. The length compensation takes place automatically depending on the set angle.

- Electronic crosscut fence with 2 crosscut stops and extendable to a maximum of 3400 mm

- automatic angle/length compensation

The overhead saw guard can be unlocked with one movement and completely swung away from machine table area. If desired, the overhead saw guard can be unlocked directly via a lever on the hood.

Upon request we can equip your kappa with LED lighting and an integrated tool compartment for 4 saw blades with a diameter of max. 400 mm, 1 saw blade with a diameter of max. 550 mm and 2 splitters.

The convenient parts list holder with A4 clipboard is mounted on the overhead control panel, keeping your parts lists in sight at all times.

kappa 550

The rip fence can be fitted with an electronic digital-display. The perfect integration of the electronic unit allows you to turn the display around 90°, so the values are clearly and exactly readable from the operating area. Additional functions such as the input of successive measurements make your daily working life easier. Further highlights:

- Bright, easy to read LED display

- No batteries are required due to a direct connection to the machine's power supply

- Automatic recognition of vertical or horizontal fence position

- Measurement compensation of the saw blade tooth width

Technical data

Electrics

Saw unit

Control Systems

Safety devices

Cutting width and rip fence

Sliding tables anodized, “X-Roll” guiding system

Outrigger table and crosscut fence

Packaging

Machine control

Important Accessories

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP USA Headquarters Details

USA Headquarters | New Castle, Delaware Showroom

2 Lukens Drive, Suite 100-400

New Castle, DE 19720

Tel.: 866-792-5288

Fax: 302-322-9865

Business Hours: Mo. – Fr. | 8am – 5pm (EST)

FELDER GROUP USA Dallas Details

South Division | Dallas, Texas Showroom

1420 Halsey Way / Suite 100

Carrollton, TX 75007

Tel.: 866-792-5288

Business Hours: Mo. – Fr. | 8am – 5pm (CST)

FELDER GROUP USA West Sacramento Details

West Division | West Sacramento, California Showroom

1747 Enterprise Blvd.

West Sacramento, CA 95691

Tel.: 866-792-5288

Fax: 916-375-3194

Business Hours: Mo. – Fr. | 8am – 5pm (PST)

FELDER GROUP USA Anaheim Details

West Division | Anaheim, California Showroom

3531 E. Miraloma Ave., Unit 1

Anaheim, CA 92806

Tel.: 866-792-5288

Business Hours: Mo. – Fr. | 8am – 5pm (PST)

FELDER GROUP USA Denver Details

West Division | Denver, Colorado

Tel.: 866-792-5288

Business Hours: On appointment