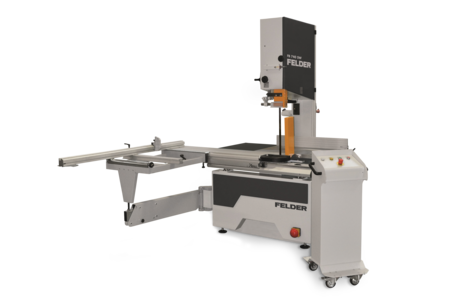

Bandsaw with sliding table FB 940 S

The bandsaw with sliding table for the really tough challenges.

The new Felderbandsaws with "X-Roll" sliding table offer great cutting heights, large support surfaces and variable cutting speeds for perfect results in industrial use. The powerful motor with a maximum power of 11 kW together with up to 620 mm cutting height and sliding table lengths from 1550 to 3700 mm bring easy handling, absolute precision and highest efficiency to every workshop. With variable cutting speeds, bandsaw blade lubrication and many other system solutions, the bandsaws guarantee perfect results and universal applicability.

In addition to woodworking, the bandsaws are also ideal for cutting shaped pipes in metalworking or for cutting insulating materials in plastics processing companies. With the Felder Heavy Duty Line bandsaws, special precision cuts of mixed materials, such as wood-aluminium windows, are done with outstanding results.

The "SW" models were specially designed to meet the high demands of non-stop operation or increased loads. The more powerful motors offer maximum performance in industrial applications and the wider rollers allow the use of large bandsaw blades of 50-90 mm width.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Variants

Models- Your benefits

Details

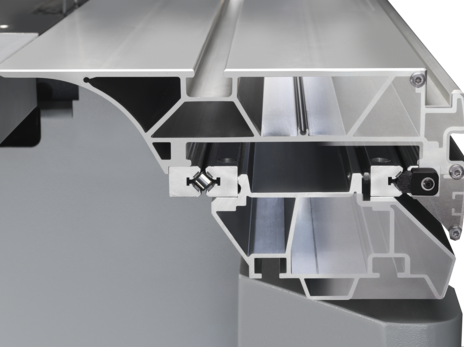

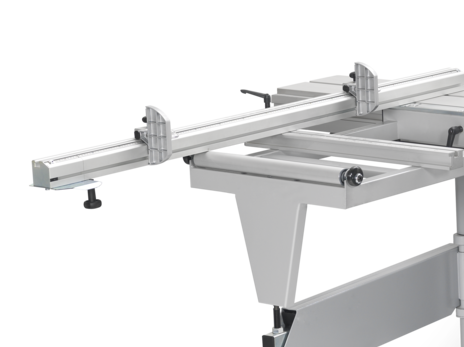

The "X-Roll" sliding table guarantees highest precision. Durable guides with the well-proven linear guiding system ensure absolute smooth running due to the roller bearing forced guidance. Due to the solid profile construction the sliding table is completely torsion resistant. Protected from dust and absolutely maintenance-free, the "X-Roll" sliding table ensures perfect woodworking for many years. The 1500, 2050, 2500, 3200 or 3700 mm format sliding table guarantees maximum precision and convenience even when cutting large-dimensioned materials.

The outrigger table with integrated workpiece roller offers maximum support surface for easy feeding of large-sized workpieces. The crosscut fence with coupling system and ergonomic scale or read-off lens on the fence stops guarantees precise adjustment and cross cuts up to 2600 mm. The crosscut fence can be swivelled from 90° - 45° and has a standard fence stop. A fixed reference position is provided at 90°.

The powerful motor with 3x400 V and 50 Hz delivers absolute best performance and outstanding results when processing a wide range of materials.

FB 740 S: 5.5 kW (7.35 kW optional)

FB 740 SW: 7.35 kW (9.2 kW optional)

FB 940 S: 7.35 kW

FB 940 SW: 11 kW

The new bandsaw models are equipped with one upper and one lower table saw blade guide including precision-adjustable side and rear rollers as well as a lockable adjusting screw. The rear roller prevents the blade from being pushed back during cutting, the left and right side roller support the blade when pressure is applied from the side. This is a significant advantage when cutting curves, for example.

The close-fitting guide blocks support the bandsaw blade laterally so that it does not run off even at high cutting heights. The roller on the back of the bandsaw guide stabilizes the blade to the rear. Due to the bronze inserts, the heat generated during cutting is ideally dissipated, thus considerably extending the service life of the bandsaw blades.

The bandsaw guides with ceramic inserts guarantee excellent cutting results and maximum blade stability with four guiding blocks positioned directly adjacent to the saw blade. The flat surface ensures reduced noise emissions and considerably less friction resistance. With reduced friction and less heat generation, ceramic guides are practically wear-resistant and enable an extremely long useable life and consistent cutting quality when compared to conventional roller guides.

The front third of the two solid steel wheels are cambered. Bronze scrapers are fitted in the upper and lower part of the bandsaw to protect it from dirt and ensure high concentricity. Ideal equipment for cutting damp and wet wood, when using lubricants or for working with aluminium, bronze, copper or composite materials.

Optionally the band saw can be equipped with rubber-coated wheels. The elasticity of the rubber coating minimises the occurring loads and as such prevents the blade from moving off its position. It is also possible to use narrower bandsaw blades with crosswise teeth.

The belt lubricating device supplies the bandsaw blade with release agents via a felt pad and thus cleans and protects it from resin and contamination.

With the optionally available, electro-pneumatic belt lubrication device, the release agent is sprayed onto the saw blade against the running direction of the blade via a nozzle. Due to the lubricating and at the same time cooling effect, this is a considerable advantage, especially when processing plastics or metals.

The clamping system allows flat and round components of a diameter of 50 to 600 mm to be clamped on the sliding table. The clamping is done pneumatically, using two clamping jaws that slot into the table groove.

The Felder linear laser for bandsaws makes it possible to project the cutting line of your workpiece and serves as an optical guide when cutting. This makes it possible to align the workpiece in advance and minimises waste. The mounting plate allows the linear laser to be retrofitted on to any bandsaw.

FB 740 S

The variable cutting speed between 320-1120 m/min is particularly recommended when processing light metals and materials that tend to smear during cutting.

The convenient hydraulic blade tensioning system guarantees absolute repeatability due to the precise display of the tension on the pressure gauge. Due to the constant optimum blade tension, you also benefit from a longer service life of the bandsaw blades.

FB 740 SW

The "SW" equipment was specially designed to meet the high demands of non-stop operation or increased loads. The more powerful motors offer maximum performance in industrial applications and the wider rollers allow the use of large bandsaw blades of 50-90 mm width.

The variable cutting speed between 320-1120 m/min is particularly recommended when processing light metals and materials that tend to smear during cutting.

FB 940 S

The variable cutting speed between 320-1120 m/min is particularly recommended when processing light metals and materials that tend to smear during cutting.

The convenient hydraulic blade tensioning system guarantees absolute repeatability due to the precise display of the tension on the pressure gauge. Due to the constant optimum blade tension, you also benefit from a longer service life of the bandsaw blades.

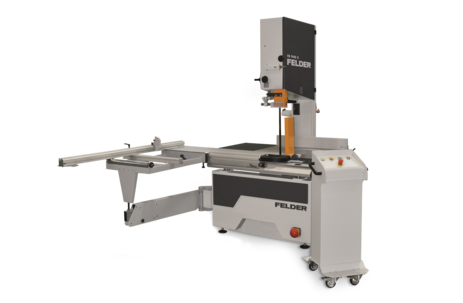

FB 940 SW

The "SW" equipment was specially designed to meet the high demands of non-stop operation or increased loads. The more powerful motors offer maximum performance in industrial applications and the wider rollers allow the use of large bandsaw blades of 50-90 mm width.

Technology Data

Electrical setup

Band Saw Unit

Sliding Tables

General

Important Accessories

Customer service & maintenance

Do you have any questions?

Showrooms

Felder Group Canada Details

Canada Headquarter | Mississauga, Ontario Showroom

1745 Meyerside Drive, Unit 4/5/6

L5T 1C6 Mississauga, ON

Tel.: 1-866-922-8879

Ultimate Tools Details

Dealership

3847 First Avenue Unit 102

V5C 3W6 Burnaby, BC

Tel.: 1-866-971-9663

[email protected]

Wallace Machinery & Tool Co. Ltd. Details

Dealership

151 Agri Park Road

R0G 1N0 Oak Bluff, MB

Tel.: 1-204-788-1199

[email protected]

Wooden Edge Inc. Details

1372 Mountain Ave

R2X 3A3 Winnipeg, MB

Tel.: 1-800-340-0233