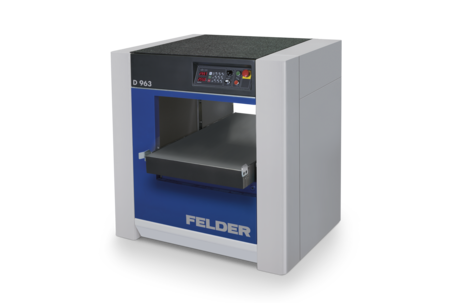

Thicknesser D 963

The D 963, the largest from the thicknessing range from the FELDER programme

At first glance the machine design demonstrates the core competencies of the Felder D 963: strength, stability and ease of use at the highest level. This thicknesser with a thickness planing width of 630 mm has been optimised for high performance and therefore it is a powerhouse in performance and precision. Innovative controls, large and heavy precision components show first class workmanship through maximum precision and durability. The Felder D 963 comprises approved Felder components such as the massive thicknesser table, the precise setting accuracy and the four trapezoidal spindles. These components have been extended with new, innovative developments, such as the Silent-Power® spiral cutterblock which provides an excellent thickness planing result. Professional users in trade, commerce and industry benefit from perfect thickness planing results at maximum stress.

When aiming for gentle and careful workpiece processing, the thicknesser with 630 mm planing width has nevertheless remained a powerhouse in terms of performance and precision. Large-sized, heavy-duty precision components convince with first-class workmanship, maximum precision and durability. Proven Felder system components such as the massive thicknesser table and the four trapezoid threaded spindles combine the D 963 into a completely new dimension of the quality of the planing result.

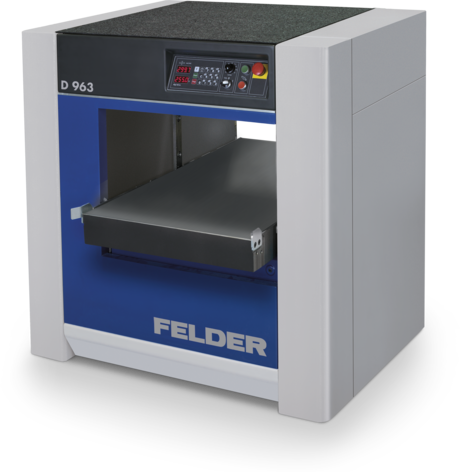

The "Digi-Drive" control guarantees maximum ease of use: enter the desired dimension, press start and the thicknesser table adjusts exactly to the position you require. LED displays for the required and actual value. Additional functions: incremental adjustments, 4 programmable thicknessing table positions. Professional machine operators from small and big workshops all the way through to industry profit from perfect jointing results.

On the basis of the legendary spiral blade cutterblock Silent-Power®, a special cutting geometry has been developed which guarantees perfect planing results for plastics. The rubberised in- and outfeed rollers allow gentle workpiece transport of particularly sensitive surfaces. Also, the adjusted feed speed from 2 to 8 m/min and the maximum chip removal of 3 mm were specially designed to meet the high demands of modern plastics processing.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Variants

Models- Your benefits

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

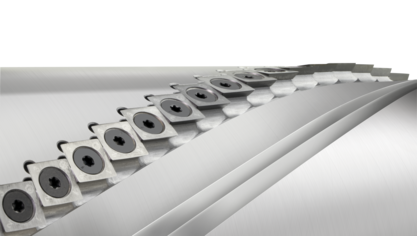

Exclusive for planer/thicknessers from the Felder Group. The Silent-Power® spiral cutterblock reduces noise emissions by more than half when planing. The continuous pulling cut ensures tear-free results when planing all types of wood. With this revolutionary new development from Format4 you are obtaining all of the advantages of a spiral cutterblock at considerably lower operating, investment and adjustment costs. The advantages of the Silent-Power® cutterblock at a glance ...

- Extremely quiet, noise is reduced by half

- Usable blade life twenty times longer than standard blades

- Four highly precise cutting edges on each knife

- Optimised chip extraction and reduced chip volume

- Tear-free planing results

- Reduced power consumption when compared to similar systems

The solid cast iron cutterblock housing is built for heavy duty work. We can also provide rubber outfeed rollers as an option. The pressure beams combined with the rubber feed roller serve to machine simultaneously workpieces of differing width.

D 963

D 963 c-tech

On the basis of the legendary spiral blade cutterblock Silent-Power®, a special cutting geometry has been developed which guarantees perfect planing results for plastics.

Regardless of the type of wood and grain, the variable feed speed of between 2-8 m/min always guarantees a perfect thicknessing result.

Technology Data

Electrical setup

Cutterblock

Thickness Planer and Feed Drive

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

Felder Group Canada Details

Canada Headquarter | Mississauga, Ontario Showroom

1745 Meyerside Drive, Unit 4/5/6

L5T 1C6 Mississauga, ON

Tel.: 1-866-922-8879

Ultimate Tools Details

Dealership

3847 First Avenue Unit 102

V5C 3W6 Burnaby, BC

Tel.: 1-866-971-9663

[email protected]

Wallace Machinery & Tool Co. Ltd. Details

Dealership

151 Agri Park Road

R0G 1N0 Oak Bluff, MB

Tel.: 1-204-788-1199

[email protected]

Wooden Edge Inc. Details

1372 Mountain Ave

R2X 3A3 Winnipeg, MB

Tel.: 1-800-340-0233