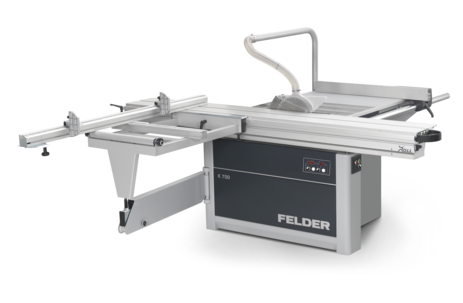

Sliding Table Panel Saw K 700

K 700: guaranteed Felder quality with every cut regardless of the dimensions

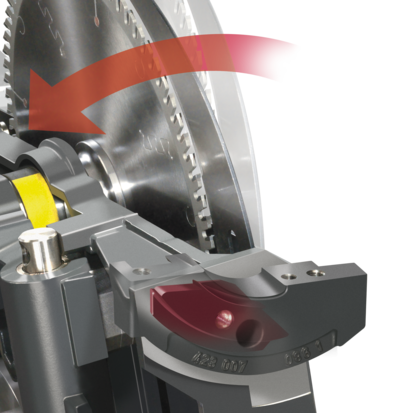

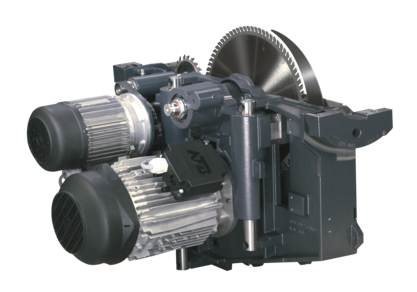

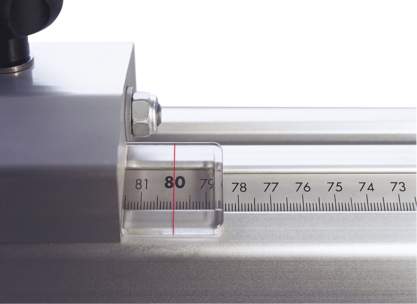

It is the technologically unique solutions and top class operating comfort that particularly impress about the K 700 sliding table saw from Felder. The 1300 and 1500 outrigger tables guarantee efficiency and precision even when processing heavy or bulky workpieces. The innovative saw aggregate with precision guiding system for exact angle adjustments, tilting saw blade and precise lineal height adjustment is just one of the numerous Felder innovations guaranteeing perfect woodworking results. The new swing away overhead saw guard offers maximum flexibility and maximum operating safety. Six year guarantee on the patented “Easy-Glide” tilting guide system and 10 year guarantee on the tried and tested Felder “X-Roll” sliding table system guarantee maximum reliability for years to come. The optional “Power-Drive” package with electronical saw blade height and angle adjustment accurate to a tenth of a millimetre bring precision and operating comfort to your workshop that are simply another class.

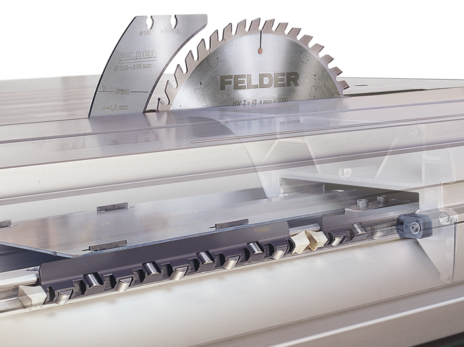

The enhanced circular saw unit with the patented tilt segment "Easy-Glide" enables the combination of a main saw blade with a Ø from 250 mm to Ø 315 mm and a Ø 120 mm scoring unit.

The c-tech product line offers specially designed equipment options for processing plastics and composite materials.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Variants

Models- Your benefits

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

The enhanced circular saw unit with the patented tilt segment "Easy-Glide" enables the combination of a main saw blade with a Ø from 250 mm to Ø 315 mm and a Ø 120 mm scoring unit.

The electrically driven Ø 120 mm scoring saw blade ensures tear-free cuts and is perfect for materials with a surface that easily tears off. The scoring saw blade can be adjusted in height without clearance by means of easily accessible adjusting screws.

K 700 professional

K 700

Perfect results in every material with variable speed control.

Technology Data

Electrical setup

Saw and Scoring Unit

Sliding Tables

Outrigger Tables and Crosscut Fences

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

Southern office – Vietnam technique development Co., Ltd. Details

No 1/33, Binh Duc 1 town, Binh Hoa Ward, Thuan An District (Opposite to Lotte Mart, 200m pass over Ong Bo bridge crossroad)

Binh Duong province

Tel.: +84 650 6 505 888

Vietnam technique development Co., Ltd. Details

No. 160 Tran Binh, My Dinh 2 Ward, Nam Tu Liem District

Ha Noi City

Tel.: +84 4. 37555 282/283

Fax: +84 4. 3755 34