Formatinis pjaustymas kappa automatic classic

Kompaktiškos plokštės supjovimo staklės, skirtos efektyviai pjaustyti

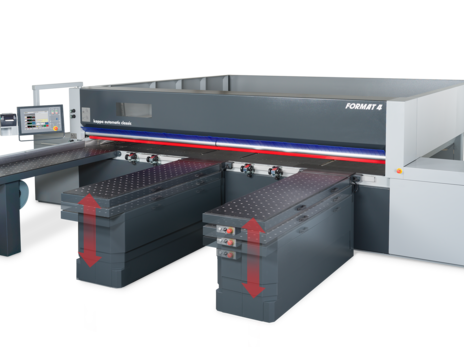

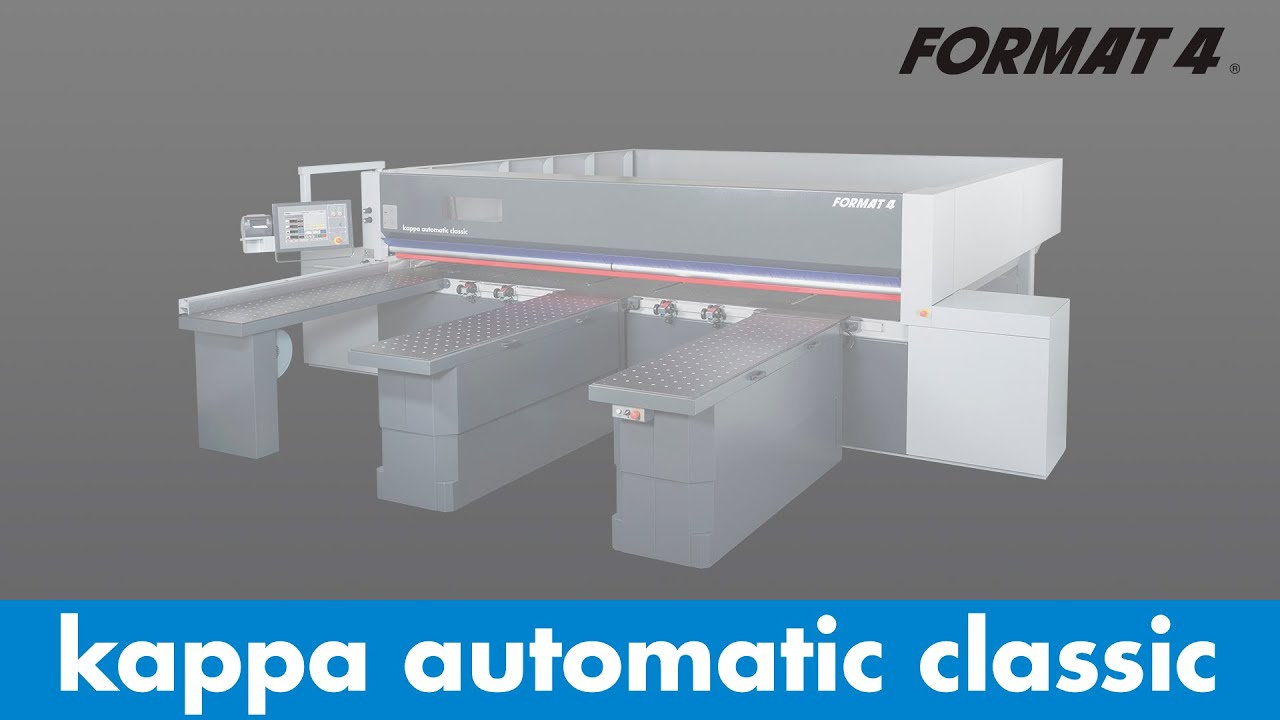

„FORMAT-4“ plokštės supjovimo staklės „kappa automatic classic“ tenkina pačių reiklausių medienos apdirbėjų poreikius efektyviai pjaudamos plokštes ir užtikrindamos geriausią kainos ir kokybės santykį. Palyginti su tokio pat pjovimo ilgio pjūklais, „kappa automatic classic“ reikia dviem kvadratiniais metrais mažesnio pastatymo ploto.

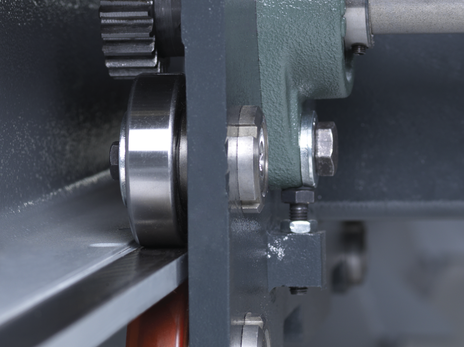

Patraukli plokštės supjovimo staklių bazinė įranga pasižymi 3 200 ir 4 300 mm pjovimo ilgiais, dviem pristatomaisiais stalais su oro pagalvės funkcija ir prispaudimo įranga, skirta naudoti pjaunant stačiu kampu. Puikius rezultatus be atplaišų užtikrina pjovimo blokas su pagrindinio pjūklo ir priešpjūklio mazgais. Pagrindiniam pjūklui su galingu 7,5 kW varikliu, 320 mm pjovimo disko skersmeniu ir 68 mm pjovimo disko iškyša padeda atskiras priešpjūklio mazgas su 0,75 kW, 150 mm skersmens priešpjūklio disku ir galimybe reguliuoti, kai pjūklas veikia. Intuityviai, greitai ir paprastai valdoma naudojantis 15" jutikliniu ekranu.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

... FORMAT4-Aukščiausios kokybės staklės, atitinkančios aukščiausius reikalavimus

- Didelis našumas nepertraukiamai pramonės gamybai

- Klientui pritaikyti optimizuoti gamybos sprendimai

- Solidus dizainas su aukščiausios kokybės komponentais

- Daugybė specifikacijų paketų su aukštųjų technologijų sprendimais

- Visiškas inžinerijos tikslumas

- Aukščiausias naudotojo komfortas

- Apdovanotas dizainas

- Kokybė ir tikslumas iš Austrijos

- Nepriekaištingas produktyvumas

- Puikus paslaugų paketas prieš pirkimą, jo metu ir po jo

- Automatikos sprendimai

- Programinė įranga ir staklės iš vieno tiekėjo

- Individualūs staklių sprendimai

detalės

Three separate fans are used for the air cushion function on the side tables. Individual control ensures convenient panel handling and resource-saving use at all times.

Thanks to the flexible operating terminal and the easy-to-see window on the pressure bar, you have always everything important in sight.

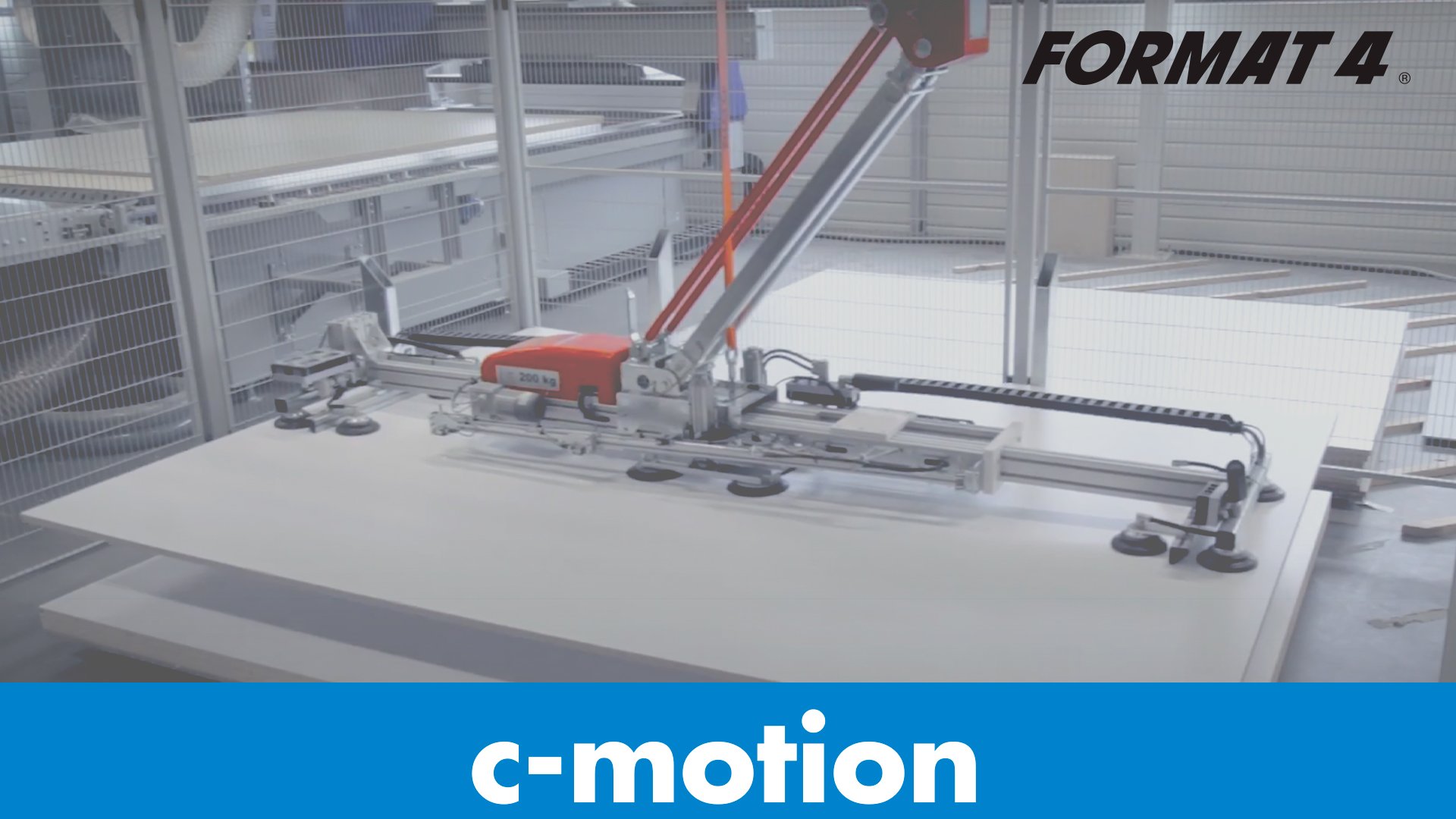

The move towards automation with automatic front lifting tables. Stacks of panels with up to 240 millimetres can be temporarily stored here and processed one plan at a time. In addition, it is possible to load a pre-commissioned panel stack and complete separate cutting plans with minimal set-up time. Here, the thickness of the panel is independent.

With the additional operating terminal on the air cushion table, you save time and increase productivity.

With the material pusher towards the cutting axis, panels can always be loaded reliably and without damage, regardless of the thickness of the material.

To take a further step towards automation, the kappa automatic classic can be equipped with the new, innovative front lifting table system. The standard side tables are replaced by solid, fully automatically controlled scissor lifting tables. This guarantees an enormous increase in efficiency and greatly enhances operating comfort.

The Format4 kappa automatic beam saw, guarantees simple operation and maximum efficiency with numerous software packages.

Klientų aptarnavimas ir priežiūra

Norite paklausti?

Showrooms

UAB FELDER Group Lietuva detalės

Pelesos g. 3 / Dzuku g. 2

LT-02115 Vilnius

Tel.: 8 5 2321987

Fax: 8 5 2321987