Sliding Table Panel Saw K 740 S

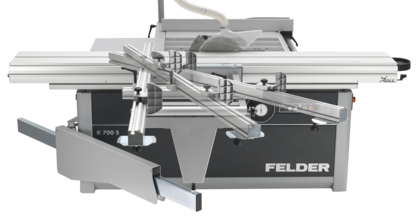

K 740 S: The new FELDER sliding table panel saw K 740 S combines large cutting height, compact size and high operating comfort

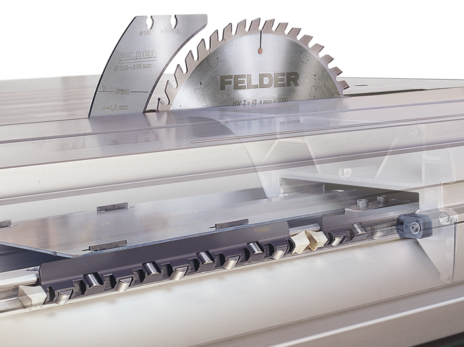

The new FELDER K 740 S convinces with the combination of performance and comfort in a space-saving, solid design. The machine is characterized by a large and powerful circular saw unit with a maximum cutting height of 140 mm when using a Ø 400 mm saw blade. It is also possible to use an electrically driven scoring unit with a Ø of 120 mm in combination with a Ø 350 mm main saw blade. Even cuts through materials with sensitive surfaces become a breeze.

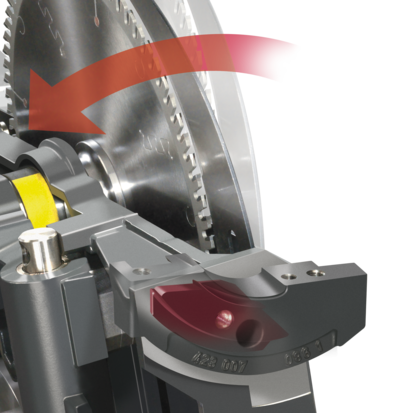

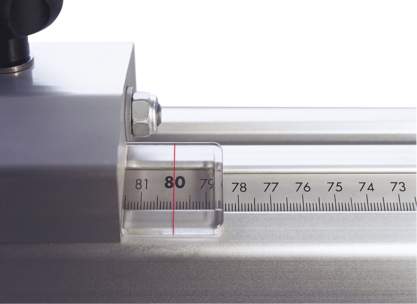

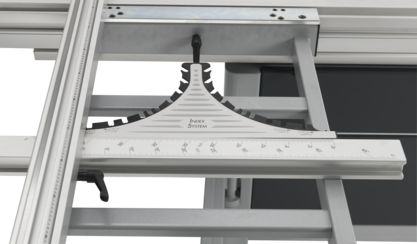

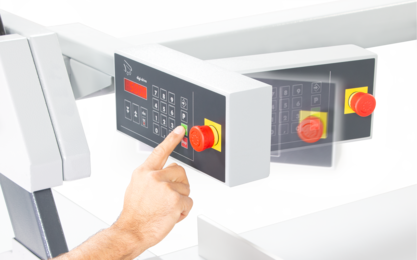

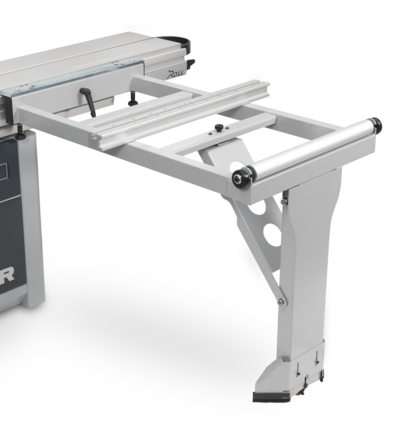

With the tilting saw blade unit and precision double guiding for precise angle and height adjustment, the K740 S guarantees a new dimension of efficiency. With the solid outrigger tables on both the Professional and S models the panel saws leave nothing to be desired. Protected from dust and absolutely maintenance-free, the X-Roll format sliding table ensures perfect woodworking for many years. The K 740 S is equipped with a tilting FELDER overhead saw guard for optimum extraction results and the highest level of work safety. The optional "Power-Drive" package with electronical saw blade height and angle adjustment accurate to a tenth of a millimetre bring precision and operating comfort to your workshop that are simply another class.

The intelligent parallel cutting fence brings superior comfort and impressive productivity to every workshop. It is an optional feature of the K 740 S, to quickly move with a tenth of a millimetre to the specified position at the push of a button, guided on a linear guide system with ball-screw bearing, thus ensuring precise cutting results quickly and easily. Six year guarantee on the patented "Easy-Glide" tilting guide system and 10 year guarantee on the proven FELDER "X-Roll" sliding table system ensure maximum reliability for years to come.

Also perfect for machining non-ferrous metals, plastics and composite materials: Upon request, the K 740 models can be equipped with variable speed control and minimum quantity lubrication.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

The advanced circular saw unit with the patented tilt segment "Easy-Glide" impresses with a cutting height of 140 mm when using a Ø 400 mm saw blade. The electric scoring unit for scoring blades with a diameter of 120 mm can be used in combination with a Ø 350 mm saw blade.

The electrically driven Ø 120 mm scoring saw blade ensures tear-free cuts and is perfect for materials with a surface that easily tears off. The scoring saw blade can be adjusted in height without clearance by means of easily accessible adjusting screws.

- For rip and formatting cuts of large panel material

- Floor guides are height adjustable, 4.5 m in length, consists of 3 sections

Technology Data

Electrical setup

Saw and Scoring Unit

Sliding Tables

Outrigger Tables and Crosscut Fences

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

LEADER F&W CO., LTD. Details

5F, No.32, Ln.205, Sec.1, Changxing Rd. Luzhu Dist.

33860 Taoyuan City

Tel.: 886-3-352-6208

Fax: 886-3-352-6908