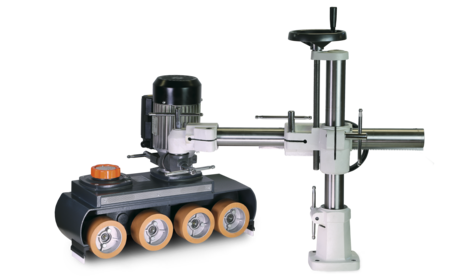

Tilting spindle moulder

new

profil 92 M e-motion

- Electro-spindle with variable speed and HSK 63F interface

- Double pivoting 2 x 46°

- Swing-away fence stop with two controlled axes

- HSK 63F quick tool change system

- Table opening with controlled, eccentric insert rings

- Intuitive e-motion control for moulder spindle, fence stop and table opening