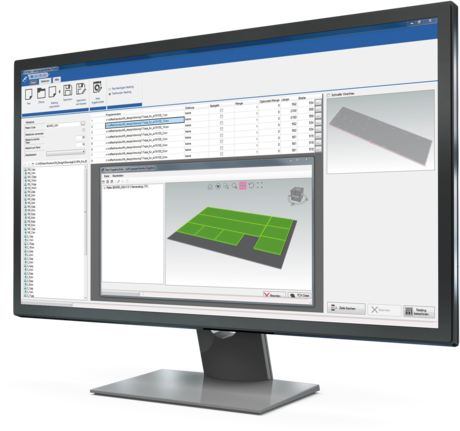

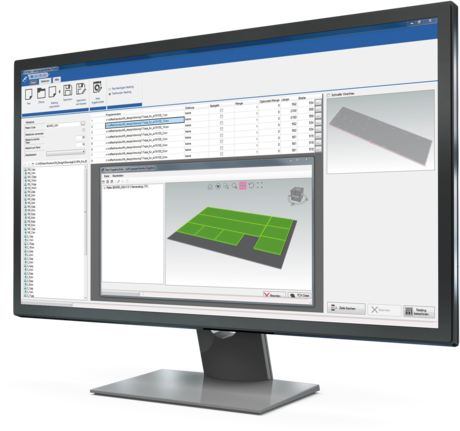

Software F4Nest

Material-saving panel processing with nesting optimisation.

Saving space, material and time the CNC cutting optimization software F4®Nest interlaces furniture and other milled parts. The result will be presented in 3D. Cutting of panel material in the nesting process is efficient, profitable and reduces cut-off.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

Make more of your ideas with F4Nest!

Details

With the CNC cutting optimisation software F4Nest, furniture and other milled parts are nested within one another to save space, material and time. The result will be presented in 3D. Cutting of panel material in the nesting process is efficient, profitable and reduces cut-off. Cutout areas can be cleared for other components.

The panels are perfectly utilised based on their settings and one of the most powerful 3D cores of the latest generation optimizes nesting for profitable results at the highest quality standards.

The graphical representation of the finished nest with 3D editing capability, rotation and individual assignability simplifies operation and guarantees maximum flexibility. The identification of individual parts is possible at any time and ensures constant control over the project.

The manual control allows finished nests to be customised and adapted for cross-project material compositions. The manual changes of nesting proposals through adding, rotating, and adjusting new parts, allows for an optimal use of residual space.

The label generator offers flexible design such as the use of any number of free space for naming or integrating images or barcodes. A template database and the direct recognition of the label size from the printer setting facilitate and accelerate the workflow.

Intelligent "nesting" of free-form parts ensures the best possible utilization of the panel. Various milling strategies and process sequences can be predefined, thus perfectly complete the individual 4.0 work optimisation.

Do you have any questions?

Showrooms

OLSA Ay Details

Tupalankatu 4

15680 Lahti

Tel.: +358 10 820 7200