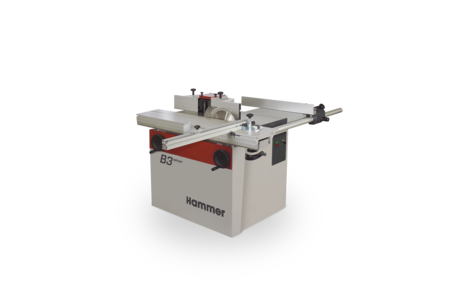

Saw/Spindle Moulder B3 winner Comfort

For the professional, discerning user

By choosing the B3 you are investing in a premium circular saw and moulding machine.

Fast and easy set-up precise adjustments are standard features included in the Comfort Package.

The rearward tilting moulder unit and the Hammer format sliding table ensure precise performance: this is how we define quality woodworking machines for the discerning professional user.

Hammer. Affordable functionality and reliability

Since 1997 Hammer has been producing high quality yet affordable woodworking machines for do-it-yourselfers and small businesses. Robust, durable, space-saving and precise in its operation. Quality products that simply make woodworking fun.

The most important highlights at a glance

Variants

Models- Your benefits

... why you should choose a Hammer

- Excellent value for money

- Decision making reliability for many years to come

- Innovative machine technology

- Solid cast iron tables and units

- High quality, unique detail solutions as part of the standard package

- Top quality manufacturing with strict quality guidelines

- Remarkably user friendly

- Classic design

- Quality and precision from Austria

- Compact functionality

- Mobile as an option

- Minimal space requirement

- Quickest changeover times

Details

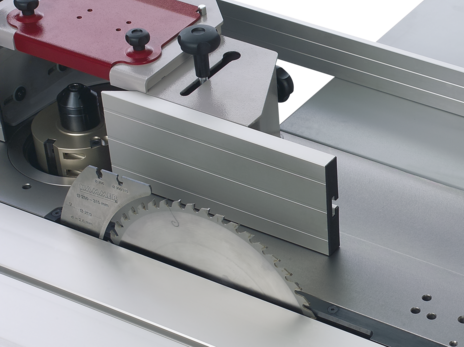

Professional equipment: “220” spindle fence for max. tooling diameter 220 mm, MULTI adjustment system for spindle fence “220” enabling parallel alignment and quick setup

B3 winner Comfort

Your Hammer spindle tilts “rearward” for operational comfort and the additional following reasons:

B3 winner

Your Hammer spindle tilts “rearward” for operational comfort and the additional following reasons:

B3 basic

B3 perform

Your Hammer spindle tilts “rearward” for operational comfort and the additional following reasons:

Technology Data

Electrics

Saw Unit

Spindle Moulder Unit and Spindle Fence

Anodised Format Sliding Table

Outrigger Tables and Crosscut Fences

Weight

Important Accessories

Customer service & maintenance

Do you have any questions?

Showrooms

ФЕЛДЕР ГРУП БЪЛГАРИЯ Details

РУМ Кремиковци, етаж 2

Квартал Ботунец

1870 София

Tel.: +359 87 877 7750