Tilting Spindle Moulder F 900 M

The heaviest built Felder spindle moulder ever

The new, optimised machine concept of the F 900 M spindle moulder ensures that it is the perfect solution for all requirements of professional woodworking. Maximum machine construction precision from Austria and high quality premium components offer total precision, top user comfort and guaranteed reliability. Numerous innovations and proven Felder quality ensure that the F 900 M is an absolute highlight in its class.

Highlights:

- Solid cast iron table offering vibration-free stability

- Maximum ease of operation with “Power-Drive”: Electrical height and angle control

- Felder spindle quick change system: quick changeover ensuring maximum productivity

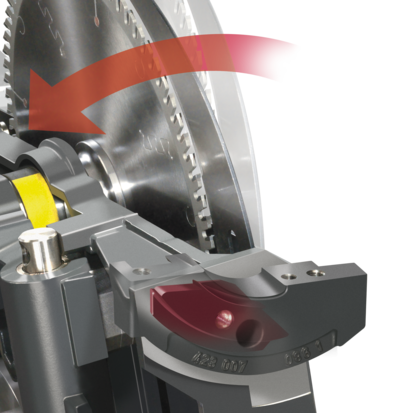

- Maximum operating safety: Spindle tilts rearwards from 90°-45°

- Maintenance free tilting segment guide “Easy-Glide” with 6 year guarantee

- 320 mm table opening – a particular advantage when panel raising

- Reliable repeatability and precise quick settings: The Felder MULTI-adjustment system

- Variable speed control up to 11,000 rpm – perfect results in every material

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

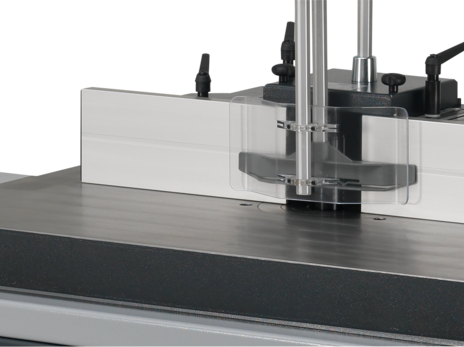

The solid cast iron moulding table is 1200 mm in width, with the large working surface ensuring maximum stabitily. The tried and tested Felder cast iron extensions can also be used when processing larger workpieces to extend the table up to a total length of 2200 mm.

Technology Data

Electrical setup

Spindle Moulder Unit and Spindle Fence

Through feed

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP Australia in NSW/ACT Details

Unit 1, 125 Russell Street

NSW 2750 Emu Plains

Tel.: (02) 4735 1011

Fax: (02) 4735 8222

Show room open times: Monday – Friday 08:30 – 17:30

FELDER GROUP Australia in Victoria Details

Please note: New Felder Group Victoria details

3/353 Dorset Road.

VIC 3153 Bayswater

Tel.: Victoria East: +61 (0) 478 832 228 // Victoria West: +61 (0) 411 277 390

FELDER GROUP Australia in Western Australia Details

49 Competition Way

Wangara, 6065 Western Australia

Tel.: (08) 9209 3055

Fax: (08) 9209 3099

Show room open times: Monday – Friday 08:30 – 17:00

FELDER GROUP Australia in QLD/NT Details

4/ 14 Buttonwood Place

QLD 4110 Willawong

Tel.: 0418 435 204

Show room open times: Monday – Friday: By appointment.