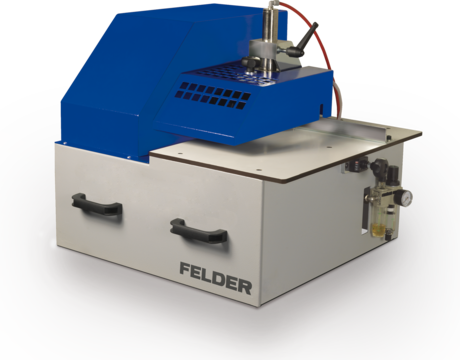

Corner rounding machine ERM 1050

This should be in every small workshop!

1 - 2 - 3 – finished rounded work-piece corners now only in 3 seconds!

You can now round ABS and PVC corner edges in less than 3 seconds. Simply place the workpiece into the unit, press the pedal and the corner is rounded. It really is that simple and precise. The new Felder corner rounding unit offers professional processing of all types of workpiece edges including edges of post or soft forming materials.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

Customer service & maintenance

Do you have any questions?

Showrooms

Felder Georgia LLC Details

WOODMASTER

67 Levan Ghoghoberidze St

0165 Tbilisi

Tel.: +995 32 275 22 90

E-Mail: [email protected]