Combination Machine CF 741 S professional

A perfect combination of 5 stand alone machines

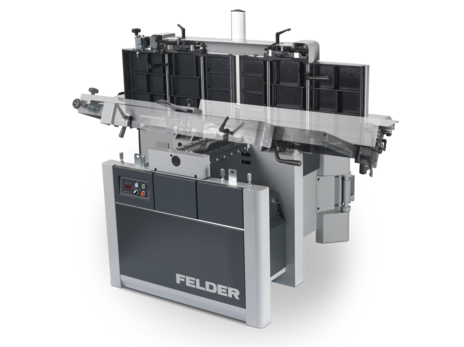

Everything you need for perfect woodworking results in just two and a half square metres: The Felder CF 741 woodworking centre combines the advantages of five stand alone machines and brings high performance, precision and shortest changeover times into every workshop. Planing, moulding, cutting and drilling – a top quality workshop in one machine. With the Professional package the operating comfort is increased even further ensuring simple processing of larger workpieces.

Highlights:

- High quality 700 series aggregates guarantee reliable quality and precision

- Simple, syncronised opening of the solid planing tables

- Optimised planing fence design ensures the smallest possible space requirement

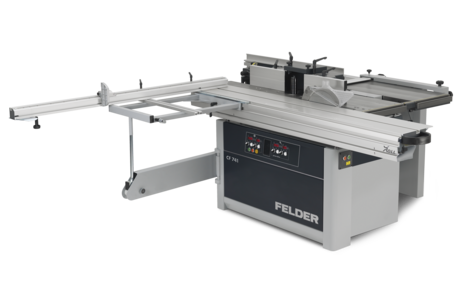

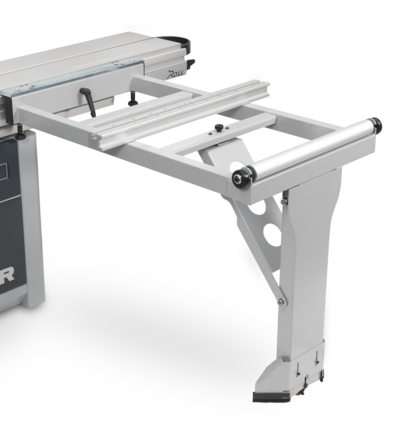

- 10 year guarantee: “X-Roll” sliding table for maximum load bearing

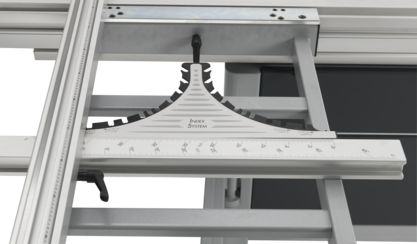

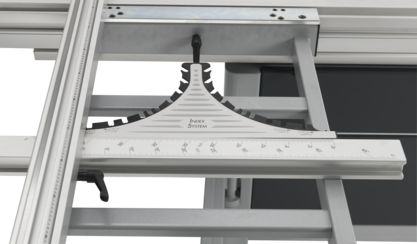

- Tried and tested Felder spindle quick change system: Felder MULTI adjustment system

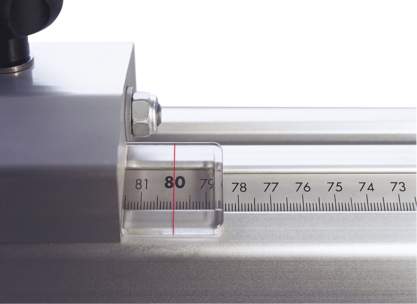

- Optional: Height and angle adjustment of the saw and spindle accurate to a tenth of a millimetre as well as thicknessing height adjustment with the electronic “Power-Drive” control.

- Maintenance free tilting guide segment “Easy-Glide” with 6 year warrenty.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Variants

Models- Your benefits

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

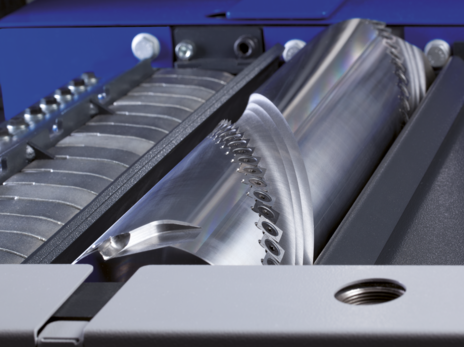

Exclusive for planer/thicknessers from the Felder Group. The Silent-Power® spiral cutterblock reduces noise emissions by more than half when planing. The continuous pulling cut ensures tear-free results when planing all types of wood. With this revolutionary new development from Format4 you are obtaining all of the advantages of a spiral cutterblock at considerably lower operating, investment and adjustment costs. The advantages of the Silent-Power® cutterblock at a glance ...

- Extremely quiet, noise is reduced by half

- Usable blade life twenty times longer than standard blades

- Four highly precise cutting edges on each knife

- Optimised chip extraction and reduced chip volume

- Tear-free planing results

- Reduced power consumption when compared to similar systems

Simple blade settings, carried out incredibly quick - accurate to a tenth of a millimetre, standard with FELDER! Resin free locking screws and the self-setting knives make it possible to change the blade in less than 2 minutes. Time consuming adjustments and purchasing of expensive setting gauges are a thing of the past. The advantages at a glance ...

- Quick and effortless knife change

- Self-setting blades for high precision when changing the blades

- No resin buildup on the clamping bolts.

- Quiet operation thanks to enclosed design

- Excellent durability of knife edges

CF 741 S professional

- For rip and formatting cuts of large panel material

- Floor guides are height adjustable, 4.5 m in length, consists of 3 sections

CF 741 professional

CF 741

Technology Data

Electrical setup

Cutterblock

Thickness Planer and Feed Drive

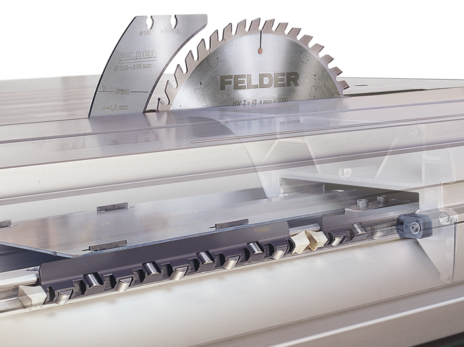

Saw and Scoring Unit

Spindle Moulder Unit and Spindle Fence

Sliding Tables

Outrigger Tables and Crosscut Fences

Mortising Unit

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

Simco Qatar Details

Old Industrial Area, Al Kassarat Street Near roundabout No.2 between 3-4 , Industrial Area

P.O. Box 40553 Doha

Tel.: +974 441 13119