Software F4Integrate

All-in-one CNC software

Long-term market analyses, thousands of customer contacts and many successful projects around the world have helped define the requirements for a complete CNC software solution over the past 15 years. Our in-house software solution F4Integrate therefore meets the highest demands of modern CNC machining.

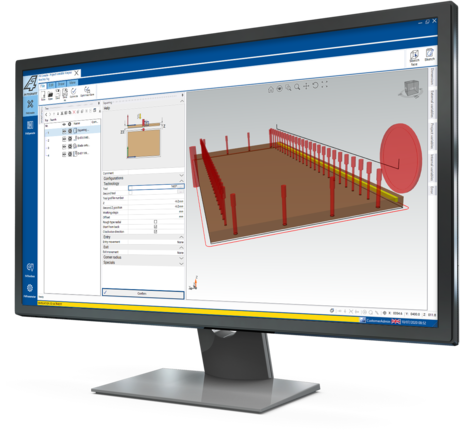

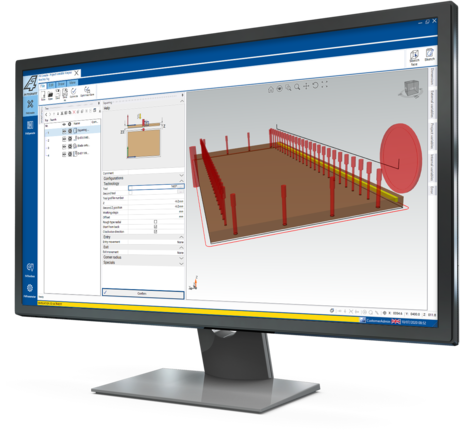

Enjoy the convenience of a modern and coordinated user interface. Tool library (F4Toolbox), programming section (CAM area with integrated CAD area, F4Create) and machine operator control panel (F4Operate) all packed into just one single screen, with a consistent and intuitive user interface.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

Put your ideas into practice with F4Integrate

Details

Even more reliability is provided by the true-to-life 3D representation of the tools, which automatically adapts to the dimensions entered in real time. Simply import or draw your desired 2D tool geometry by yourself in the integrated CAD area of F4Toolbox.

The built-in collision control of F4Toolbox prevents possible tool collisions in advance during tool loading simulation.

The integrated help images in F4Integrate can be used interactively. By clicking on the help image and its associated parameters, you can easily reach your desired target.

The component simulator included in the standard package offers you even more security when programming, because with just one click you can see all machining movements of your drilling head and spindle, regardless of 3 or 5 axes.

Draw your designs in the sketch interface.

To transfer from CAD to CAM you only have to choose between drilling, sawing, milling or emptying, F4Create calculates the rest automatically. This means that when you change the sketch, the tool path is updated in real time. Draw your DXF yourself or quickly and easily import an existing DXF with integrated layer recognition.

With F4Integrate you can generate and simulate 5-axis simultaneous machining operations in no time at all. The intuitive input of pivot and direction angles for lines and curves allows you to reach your goal with just a few inputs. Test your 5-axis machining directly and without detour in the component simulator.

Using the worldwide unique technology, the "G-Code Editor", which is behind the standard input mask of F4Integrate, you have the possibility to check and adjust your programmes in G-Code with ease. The G-code entered will be implemented directly into the user interface and returned after being confirmed. It is up to you to decide whether you prefer to enter G-code in the freeware editor or the guided interface. F4Integrate is based on the globally standardised G-code and thus enables easy integration of external CAD software developers.

These variables refer to one or more programmes in which they are defined. Customise your standard cabinet programmes in F4Operate with just a few clicks.

With the machine simulator (F4Operate), F4Integrate offers another simulation option in addition to the component simulator (F4Create). The machine simulation includes a realistic model of the CNC machine with tool changer. This saves resources (machine hours, material, tool wear) without having to do forgo your machine. Thanks to its integrated collision control, the machine simulator offers additional safety, especially during difficult machining operations.

Do you have any questions?

Showrooms

FELDER GROUP INDIA Details

India Headquarters | Mumbai Office

Survey Nos. 186D, Shed No. 653, Sasunavghar, National Highway 8,

Vasai Mumbai 401202

Tel.: 1800 274 3040

Business Hours: Monday - Friday | 10am - 7pm (IST)

FELDER GROUP INDIA Details

South Division | Bangalore Showroom

No 387, Ground Floor, 4th Main, 4th Phase , Peenya Industrial Area Phase IV,

Bangalore – 560058

Tel.: +91 80 4157 3661

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

South Division | Chennai Showroom

C/o Don Bosco Technical Campus, No.106, D’Castor Road Basin Bridge,

Chennai – 600012

Tel.: +91 84 3159 5858

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

North Division | Experience Center

A-13, Sector 67,

Noida - 201309

Tel.: +91 120 4554 344

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

West Division | Satellite Service Office

Tel.: Ahmedabad: +91 88 2832 4433

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

South Division | Satellite Service Office

Tel.: Hyderabad: +91 90 2250 7001

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

East Division | Satellite Service Office

Tel.: Bhubaneswar: +91 77 1880 0306 | Tel. Guwahati : +91 84528 12225

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)