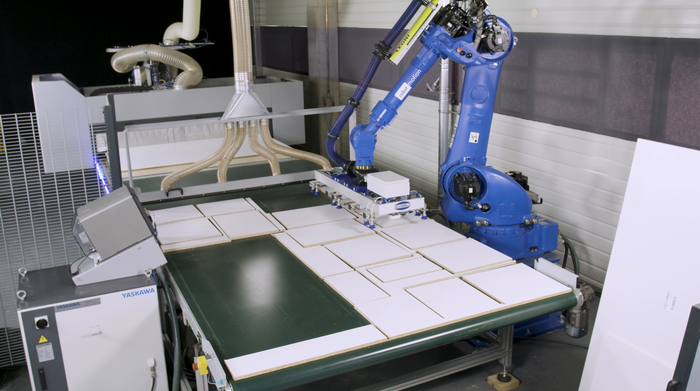

CNC Machining Centre

profit H80I

- Intelligent vacuum management system "SMART ZONING" for all machine sizes

- Unlimited and interpolating C axis

- Use of aggregate with compressed air interface for limitless use of the machine

- Numerous automation options for loading, aligning, unloading and labelling

- Optimisation options for perfect extraction results: Central suction hood, height-adjustable suction hood, under and above table extraction as well as a special compact surface extraction hood

- F4®Solutionsready