Panel Saw K3 winner

The precision circular saw for the discerning woodworker

Exact rip cuts as well as precise cross, mitre and format cuts with the smooth operation of the format sliding table. These are the qualities that discerning woodworkers like you expect in a precision circular saw.

Above and beyond that, the K3 winner gives you features that you will not find in similar types of machines, e.g. the precision circular saw unit, the cross-cut stop with the scale set at an angle, a magnifying lens to assist with making exact adjustments and the rip fence with fine adjustment system, guided on a large round bar.

The K3 winner is the choice for discerning woodworkers.

Hammer. Affordable functionality and reliability

Since 1997 Hammer has been producing high quality yet affordable woodworking machines for do-it-yourselfers and small businesses. Robust, durable, space-saving and precise in its operation. Quality products that simply make woodworking fun.

The most important highlights at a glance

... why you should choose a Hammer

- Excellent value for money

- Decision making reliability for many years to come

- Innovative machine technology

- Solid cast iron tables and units

- High quality, unique detail solutions as part of the standard package

- Top quality manufacturing with strict quality guidelines

- Remarkably user friendly

- Classic design

- Quality and precision from Austria

- Compact functionality

- Mobile as an option

- Minimal space requirement

- Quickest changeover times

Details

Technology Data

Electrics

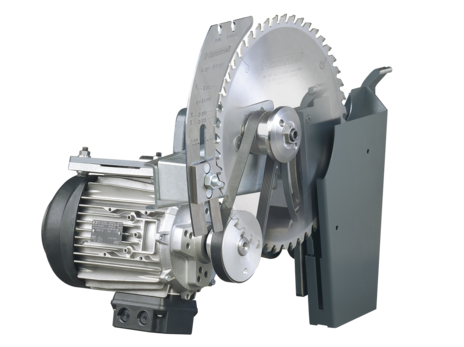

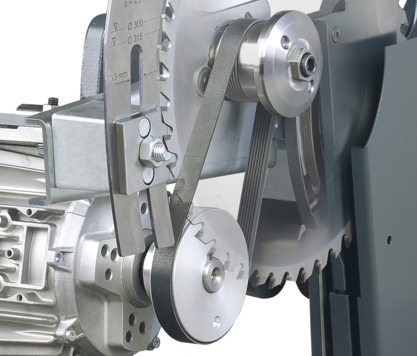

Saw Unit

Anodised Format Sliding Table

Outrigger Tables and Crosscut Fences

General

Important Accessories

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP Indonesia Details

PIKA Industrial Woodworking School

Jl. Imam Bonjol No.96

50139 Semarang, Central Java

Tel.: +62 (0) 811 296 1129

FELDER GROUP Indonesia Details

Bellagio Mall Lantai 1 No. L2.20 Kawasan Mega Kuningan Barat Kav E4.1

Kuningan Timur Setia Budi

Jakarta Selatan 12950

Tel.: +62 (0) 811 296 1129