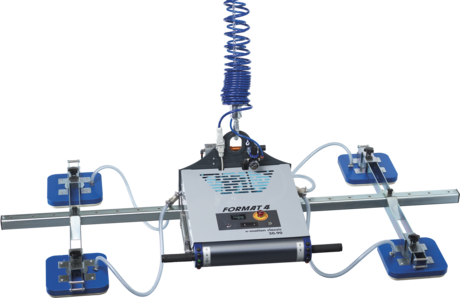

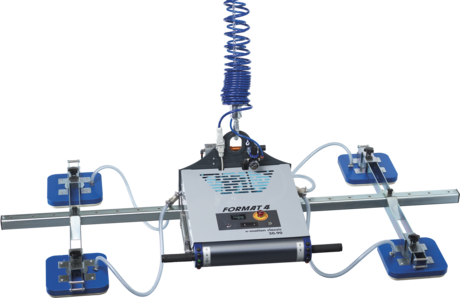

Vacuum panel lifter v-motion 20.90 classic

The perfect device for the quick and efficient transport of diverse panel materials.

The Format4 vacuum lifter v-motion classic facilitates the transport of almost any panel material within the workshop and is also designed for permeable materials - MDF above 8 mm thickness. The panels can be transported both vertically and horizontally. All the machine handling features for the hoist and for the vacuum lifter are housed in a single control unit. This makes it possible to operate the system and guide the material with just one hand.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

Variants

Models- Your benefits

... FORMAT4 Premium machines for premium requirements

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Tailor made financing solutions

Details

v-motion 20.90 classic

Suitable for dense / airtight panels up to 440 lb (200 kg) with a tilting range of 0°-90°

The perfect unit for the quick and efficient transport of laminated chipboard panels.

- Max. load capacity 440 lb (200 kg)

- Column mounted slewing crane 157 ³¹/₆₄ (4000 mm)

- Comfortable operation for easy handling

The column mounted slewing crane is available with an overall height of 9.8 ft (3 m) and a jib length of 13 ft or 19.8 ft (4 or 6 m). Swivel range approx. 250°

Thanks to its intelligent and solid construction, the column achieves a wide range of use and high stacking capacity despite its relatively low height.

6 ft. (2 m) longitudinal traverse with 4 adjustable vacuum cups of 9.8" x 9.8" (250 x 250 mm) each

Simple and intuitive controls with extra-wide operating terminal for more precision during panel transport

v-motion classic

The perfect unit for the quick and efficient transport of laminated chipboard panels.

- Max. load capacity 250 kg

- Column mounted slewing crane 4000 mm

- Comfortable operation for easy handling

Continuously adjustable swivel range 280° (2x α)

The panels can be transported both vertically and horizontally.

v-motion 15.00

The column-mounted slewing crane is available with a height of 3.2m or 3.8m and a boom length of 4m or 6m. The swivel range is approx. 280 degrees, the maximum stack height 1.2m or 1.8m.

The wall mounted slewing crane with a payload of 150 kg has a boom length of 4m or 6m and a swivel range of 250 degrees.

The smooth running rail system with a payload of 150 kg is guided on a 6m crane track length and 6m bridge length. All rollers use ball bearings and are fitted with lateral guide rollers.

Continuously adjustable swivel range 280° (2x α)

The panels can be transported both vertically and horizontally.

v-motion 15.90

Continuously adjustable swivel range 280° (2x α)

The column-mounted slewing crane is available with a height of 3.2m or 3.8m and a boom length of 4m or 6m. The swivel range is approx. 280 degrees, the maximum stack height 1.2m or 1.8m.

The wall mounted slewing crane with a payload of 150 kg has a boom length of 4m or 6m and a swivel range of 250 degrees.

The smooth running rail system with a payload of 150 kg is guided on a 6m crane track length and 6m bridge length. All rollers use ball bearings and are fitted with lateral guide rollers.

The panels can be transported both vertically and horizontally.

v-motion 25.90st

Continuously adjustable swivel range 280° (2x α)

The column-mounted slewing crane is available with a height of 3.2m or 3.8m and a boom length of 4m or 6m. The swivel range is approx. 280 degrees, the maximum stack height 1.2m or 1.8m.

The wall mounted slewing crane with a payload of 250 kg has a boom length of 4m or 6m and a swivel range of 250 degrees.

The smooth running rail system with a payload of 250 kg is guided on a 6m crane track length and 6m bridge length. All rollers use ball bearings and are fitted with lateral guide rollers.

The panels can be transported both vertically and horizontally.

Customer service & maintenance

Do you have any questions?

Showrooms

杭州费德福默木工工具有限公司 Details

杭州市西湖区西溪首座A1-3座803室

Tel.: +86 13968364987

Fax: +86 571 88918388 /Weixin ID: gh_c16c3f061903