c-tech Bandsaw FB 710 c-tech

Much more than just a bandsaw

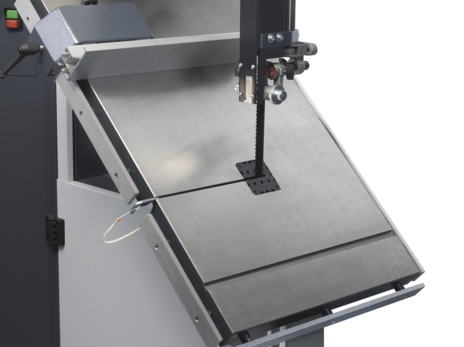

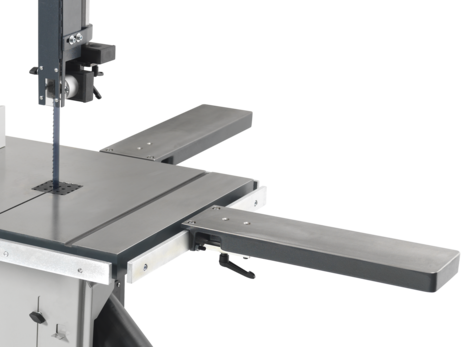

The precisely milled, cast iron machine table with 700 x 840 mm can also be extended on three sides offering more support when processing large dimensioned workpieces. In conjunction with the reinforced, low vibration machine chassis, the machine table offers maximum stability. Even when working at the maximum cutting height of 460 mm you can rely on precise results. The easy to adjust tilting table, can be positioned between -5 and +45 degrees and offers numerous applications. The parallel fence can also be positioned on its side and always guarantees a high level of working safety. The 5.5 HP motor achieves a saw blade speed of 800 rpm. With the easy to mount circle cutting and sanding units, the new Felder bandsaw really is a versatile all-rounder and a worthwhile investment for perfection in woodworking.

- Designed for high burden load solid machine chassis and cast iron fly wheels and machine table

- Standard specification: Durability, precision and cutting smoothness with the X-Life® bandsaw blade ceramic guides

- Easy and convenient bandsaw blade quick change

Variable cutting speed and flexible lubricant application

The new FB 710 c-tech was developed specifically for machining plastics, non-ferrous metals and composite materials, and impresses with its top performance in a wide range of applications Regardless of whether they are being used for the cutting of models and styling block materials such as UREOL®, PURENIT®, SikaBlock®, RAKU-TOOL® or for the trimming of the clamping edge after the thermoforming process. Felder bandsaws offer high performance when processing synthetic materials.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Specially designed for plastics, non-ferrous metals and composite materials: The new FELDER FB 710 c-tech - so much more than a simple bandsaw

The new FB 710 c-tech was developed specifically for machining plastics, non-ferrous metals and composite materials, and impresses with its top performance in a wide range of applications Regardless of whether they are being used for the cutting of models and styling block materials such as UREOL®, PURENIT®, SikaBlock®, RAKU-TOOL® or for the trimming of the clamping edge after the thermoforming process. Felder bandsaws offer high performance when processing synthetic materials.

With its 7.5 HP motor power and 460 mm cutting height, the FB 710 c-tech is one of the strongest and largest Felder bandsaws of its class to date. In combination with the innovative X-life ceramic guides included as standard, the bandsaw is unmatched in terms of wear resistance and blade stability.

Variable cutting speed and flexible lubricant application

The continuously adjustable speed control allows individual adaptation to the materials to be cut. Using the push buttons, the cutting speed can be adjusted flexibly in increments of fifty from 400 to 1400 m/min. The lubricant application ensures excellent cuts when processing non-ferrous metals. The lubricant tank can be attached flexibly to the machine by magnet.

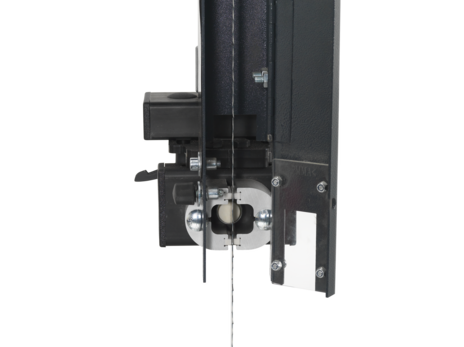

Long lasting precision through X-Life ceramic guides

Ceramic guides guarantee excellent cutting results and maximum blade stability with four guiding blocks positioned directly adjacent to the saw blade. The smooth surface results in much less friction resistance. With reduced friction and less heat generation, ceramic guides are practically wear-resistant and enable an extremely long useable life and consistent cutting quality when compared to conventional roller guides.

Details

The lubricant application ensures excellent cuts when processing non-ferrous metals. The lubricant tank can be attached flexibly to the machine by magnet.

The continuously adjustable speed control allows individual adaptation to the materials to be cut. Using the push buttons, the cutting speed can be adjusted flexibly in increments of fifty from 400 to 1400 m/min.

Technology Data

Electrical setup

Band Saw Unit

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

Southern office – Vietnam technique development Co., Ltd. Details

No 1/33, Binh Duc 1 town, Binh Hoa Ward, Thuan An District (Opposite to Lotte Mart, 200m pass over Ong Bo bridge crossroad)

Binh Duong province

Tel.: +84 650 6 505 888

Vietnam technique development Co., Ltd. Details

No. 160 Tran Binh, My Dinh 2 Ward, Nam Tu Liem District

Ha Noi City

Tel.: +84 4. 37555 282/283

Fax: +84 4. 3755 34