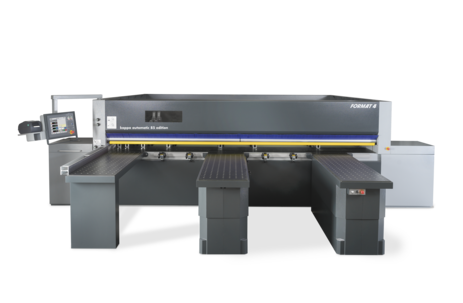

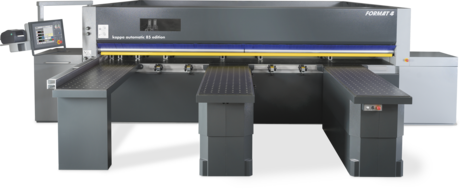

Pressure beam saw | Beam saw, horizontal kappa automatic 85 edition

Compact, efficient, precise – Pressure beam saw / Beam saw kappa automatic edition

As one of the heaviest saws in its class, the Format4 kappa automatic edition, with its steel pressure beam and material pusher, is built to last and delivers high-quality mechanical engineering. High-end cutting edges, maximum precision and maximum repeatability are the results of this philosophy. With a newly developed operating panel with touch screen control, a cutting direction against the fence as well as a a saw blade projection of 85/95 mm, it convinces in all respects. The main saw is supported by a 13.5 kW motor, a 350 mm saw blade diameter, a separate scoring unit with 1.1 kW, 150 mm scoring blade diameter and the possibility of adjustment during operation.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

Variants

Models- Your benefits

... FORMAT4 Premium machines for premium requirements

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Automation solutions

- Software and machines from a single supplier

- Tailor made financing solutions

Details

Three separate fans are used for the air cushion function on the side tables. Individual control ensures convenient panel handling and resource-saving use at all times.

The included fences can be used for cuts of panels with a veneer projecting edge. This ensures dimensional accuracy and reliable machining in this field of application as well.

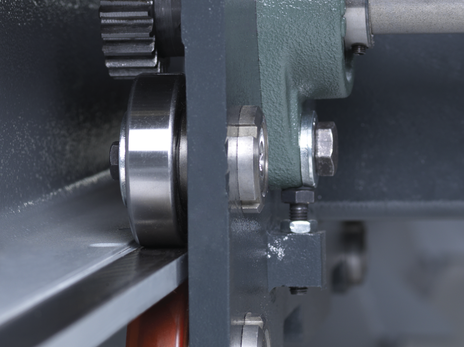

The saw carriage with main blade and scoring blade running on ground and hardened round guides ensures an extremely smooth movement and an exact cutting angle. The cutting height can be adjusted manually, pneumatically or using electro-motors.

The optionally available motorised scoring blade setting allows an accuracy of one hundredth of a millimetre via servomotors and guarantees tear-free results. The setting can be done conveniently via the control terminal.

With the additional operating terminal on the air cushion table, you save time and increase productivity.

The constant speed of the saw carriage is variable and can be set between 1–60 m/min from the control panel. The rack and pinion system on which the carriage runs guarantees a constant cutting quality regardless of the material being processed.

The Format4 kappa automatic beam saw, guarantees simple operation and maximum efficiency with numerous software packages.

kappa automatic 85 edition

Thanks to the flexible operating terminal and the easy-to-see window on the pressure bar, you have always everything important in sight.

To obtain an optimised entry angle of the saw teeth in both single and packet cutting, a saw blade projection of between 40 und 85 mm can be selected directly from the control panel. This ensures for a perfect cutting result.

Solid steel clamps, pneumatically controlled, guarantee a safe and damage-free clamping of panel stacks (opening height 85 mm) and individual small panels.

For one more step towards automation, the kappa automatic edition can be equipped with the new, innovative front lifting table system. The standard side tables are replaced by solid, fully automatically controlled scissor lifting tables. This guarantees an enormous increase in efficiency and greatly enhances operating comfort.

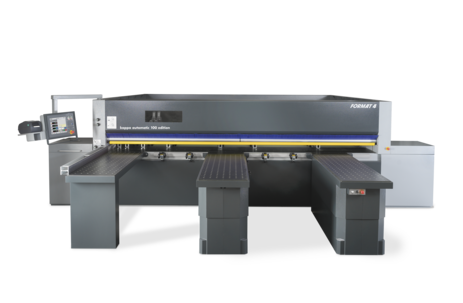

kappa automatic 100 edition

Thanks to the flexible operating terminal and the easy-to-see window on the pressure bar, you have always everything important in sight.

For the highly accurate motorised adjustment of the saw blade projection from the control panel. An additional grooving function is included as well.

Thanks to the pneumatic control, solid steel clamps ensure a safe and damage-free clamping of panel stacks (opening height 95 mm) and individual small panels. Thanks to the wide tongs at the first two positions, absolute precision in the cut to length is guaranteed and the minimum strip width is reduced as well.

For an additional approach towards automation, the kappa automatic edition can be equipped with the new, innovative front lifting table system. The standard side tables are replaced by solid, fully automatically controlled scissor lifting tables. This guarantees an enormous increase in efficiency and greatly enhances operating comfort.

Customer service & maintenance

Do you have any questions?

Showrooms

Felder Gruppe Echipamente SRL Details

Str. Turnu Magurele 270D, Cladirea Cavar Center, Corp B, Parter

041713 Bucharest

Tel.: Sales: +40 731 335337