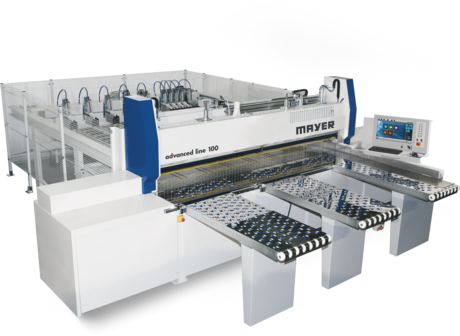

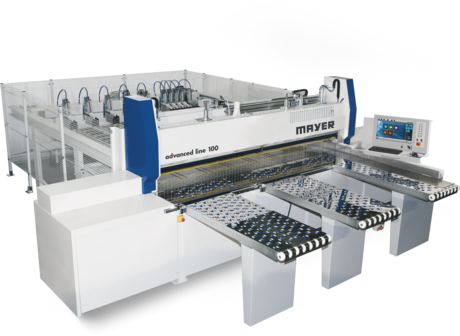

Diskiniai pjūklai advanced line 100

Plokštės supjovimo staklės aliuminiui, spalvotiesiems metalams ir plastikams

Šiandien rinkoje galima rinktis iš daugybės pjaustomų lakštinių medžiagų. Mes ne tik apdorojame aliuminį ir medieną, bet ir kuriame bei gaminame specialios konfigūracijos stakles plastikams pjauti.

Tobulumas slypi detalėse. Todėl staklių koncepcijoms sukūrėme daug detalių ir kiekvieną reikalavimą atitinkančių sprendimų. Nesvarbu, ar reikia pjauti kietaus, ar minkštas plokštines medžiagas, korines ir lengvas statybines medžiagas, valcuotus ar lietus aliuminio lakštus – pateiksime tinkamą sprendimą savo klientams. Garantuojame, kad turėsime tinkamą gaminį, net jei reikia apdoroti profiliuotus vamzdžius ar apvalius strypus.

Tvirta konstrukcija ir patvarus pjūklo vežimėlis užtikrina, kad pjovimo jėgos perduodamos be vibracijos, o dėl galingo pjūklo variklio plokštės supjovimo pjūklai tiksliai ir kokybiškai pjauna aliuminį, spalvotuosius metalus ir plastiką. Naudojant iki 75 KW galios pjūklų variklius staklės pasiekia išskirtines pastūmos vertes ir pjovimo našumą kiekvieno naudojimo metu.

- „advanced line 100“ Klasikinis įrenginis – dešimtmečių patirties rezultatas

- „advanced line 130“ Patyręs – tiksliai pritaikyta klientui

- „advanced line 160“ Universalus – daugkartiniai apdovanojimai

- „advanced line 160 turn“ Patogus – paprastas medžiagų tvarkymas

- „advanced line 200“ Masyvus – ypatingiems iššūkiams

- „advanced line 250“ Stiprus – stipriausias savo klasėje

MAYER. Technically perfect, precise and durable

The Otto Mayer machine factory has been producing panel-sizing and pressure beam saws for processing panel materials made of wood, plastics, non-ferrous metals and basic materials since 1950. The many years of experience guarantee quality and reliability at the highest level.

The most important highlights at a glance

Variantai

modeliai / -ių- Jūsų nauda

Visiems iššūkiams pasiruošę Mayer plokščių supjovimo staklės

- „advanced Line 100“ – tai dešimtmečius kauptos patirties aliuminio pjovimo srityje rezultatas, įtikinantis itin stabilia konstrukcija bei didžiausiu tikslumu ir pjovimo tikslumu. Saugi investicija į ateitį.

- Kiekvienai rinkai ir kiekvienam klientui būdingi specialūs plokščių pjovimo reikalavimai. Atsižvelgdama į šiuos reikalavimus, „advanced Line 130“ apjungia tai, kas yra išskirtina ir naudinga.

- „advanced Line 160“ – geriausiai parduodamas aliuminio plokščių pjovimo pjūklas, gavęs keletą apdovanojimų už novatoriškus sprendimus ir patentus.

- „advanced Line 160 turn“ užtikrina patogų valdymą, lengvą medžiagų tvarkymą, net ir sunkių komponentų atveju.

- „advanced Line 200“ – tvirtas plokščių supjovimo staklės, skirtos didžiausioms apkrovoms ir ypatingiems iššūkiams.

- „advanced Line 250“ yra galingiausios plokščių supjovimo staklės savo klasėje. Didžiausias našumas, išskirtinis tikslumas ir pjovimo kokybė įtikina kiekvieno iššūkio metu.

detalės

The split pressure beam facilitates minimum trimming cuts (chip or scratch cuts) regardless of the programmed board dimension. This guarantees optimal material utilisation with perfect dust extraction.

Through optimised traverse paths of the saw unit with rapid traverse shutdown. The saw unit moves at high speed until just before the material to be cut and then automatically switches to the set feed speed.

Power-saving transportation of heavy panels for highly productive one-man operation is possible thanks to the universal roller tables that are moved on linear guides.

Thanks to the pneumatic liftable table segments, heavy panels can be moved easily and without beeing damaged.

The riving knife for panels with high material tensions is mounted at the end of the saw carriage and can be mechanically connected and disconnected.

Two independent servomotors with separate measuring systems and programmable correction curves guarantee absolute precision for all travel distances.

Quickly and easily change the position of the front desk by 90 degrees and thus have a space-saving or large-sized supporting surface.

The pneumatic pressure rollers inside the rear machine table and behind the pressure beam guarantee exact 90-degree angles.

An accurate sensor for saw blade deviation ensures material-saving cuts and also reduces the costs for saw blades.

Special sound insulation systems ensure the lowest possible energy consumption. Engines that are not needed turn off automatically and dust extraction happens only where chips are really produced.

Additional tables can be moved easily and precisely on the ground linear guides.

advanced line 100

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

advanced line 130

Automatic length measurement system for trimming cuts.

Ergonomically arranged controls on the side table.

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

advanced line 160

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

advanced line 200

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

advanced line 250

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

Klientų aptarnavimas ir priežiūra

Norite paklausti?

Showrooms

UAB FELDER Group Lietuva detalės

Pelesos g. 3 / Dzuku g. 2

LT-02115 Vilnius

Tel.: 8 5 2321987

Fax: 8 5 2321987