Formatinio pjovimo – frezavimo staklės KF 700

Two professional machines in one combination

A panel saw and tilting spindle moulder – with the KF 700 saw-spindle moulder, Felder has combined two top-quality professional woodworking machines to form an unbeatable combination. Innovative detailed solutions, tried and tested Felder technology and perfect components for perfect woodworking – the answer to every challenge. Individual equipment, shortest changeover times and precise repeatability are convincing features for workshops, commerce and industry.

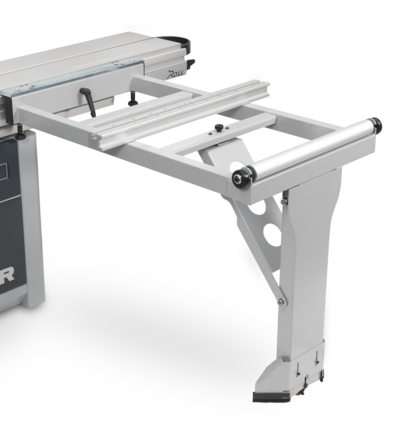

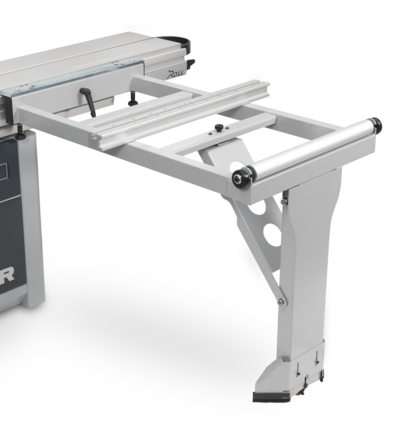

The KF 700, KF 700 Professional models, with sliding table lengths of 1300, 1550, 2050 or 2500 mm as well as 1100 and 1300 mm outrigger tables, offer sufficient space for easy in-feed and comfortable processing of large-format workpieces. For the highest requirements and maximum working areas, the K 700 S offers optional format sliding tables with 2500 or 2800 and 3200 mm and an outrigger table up to 1500 mm.

The optional „Power-Drive“ control system for precise setting and repeatability allows premium class operating comfort. Height and angle measurements of the saw blade and the spindle with tenths of a millimetre accuracy can be set quickly and checked in real time on the easy-to-read LED display.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Variantai

modeliai / -ių- Jūsų nauda

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

detalės

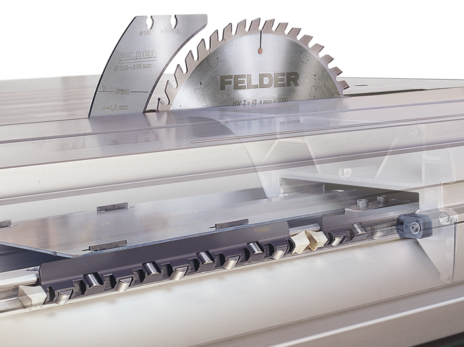

Highest operating safety and maximum flexibility when processing large dimensioned workpieces: the Felder overhead saw guard can be swung away easily and is always there where it is required.

KF 700 S professional

- For rip and formatting cuts of large panel material

- Floor guides are height adjustable, 4.5 m in length, consists of 3 sections

KF 700 professional

- For rip and formatting cuts of large panel material

- Floor guides are height adjustable, 4.5 m in length, consists of 3 sections

KF 700

Technology Data

Galingumas

Pjovimo staklės

Frezavimo staklės

Formatavimo stalai

Skersavimo stalai ir skersinės liniuotės

Kita informacija

Papildoma įranga

Transportas

Klientų aptarnavimas ir priežiūra

Norite paklausti?

Showrooms

UAB FELDER Group Lietuva detalės

Pelesos g. 3 / Dzuku g. 2

LT-02115 Vilnius

Tel.: 8 5 2321987

Fax: 8 5 2321987