Frezavimo staklės profil F 900 Z

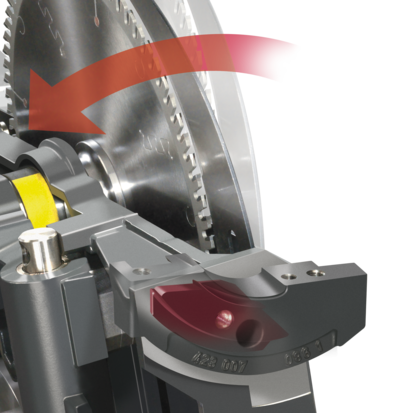

F 900 tilting spindle moulder – for exceptional performance

The Felder 900 series spindle moulders were designed to deliver exceptional performance under the most demanding conditions. The inner workings of the machine have been elegantly designed and incorporate the finest machining technology. The extremely precise construction and user friendly operation produce a perfectly machined workpiece. These features have made Felder woodworking machines a best seller worldwide.

… with “Power-Drive” its all electronic

A turn of a knob for both spindle height and angle settings. Fine adjustments to .1mm are made at the push of a button. LED displays will show actual settings to one tenth of a millimeter and one tenth of a degree respectively.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

detalės

Technology Data

Galingumas

Frezavimo staklės

Formatavimo stalai

Skersavimo stalai ir skersinės liniuotės

Pastūma

Kita informacija

Papildoma įranga

Transportas

Klientų aptarnavimas ir priežiūra

Norite paklausti?

Showrooms

UAB FELDER Group Lietuva detalės

Pelesos g. 3 / Dzuku g. 2

LT-02115 Vilnius

Tel.: 8 5 2321987

Fax: 8 5 2321987