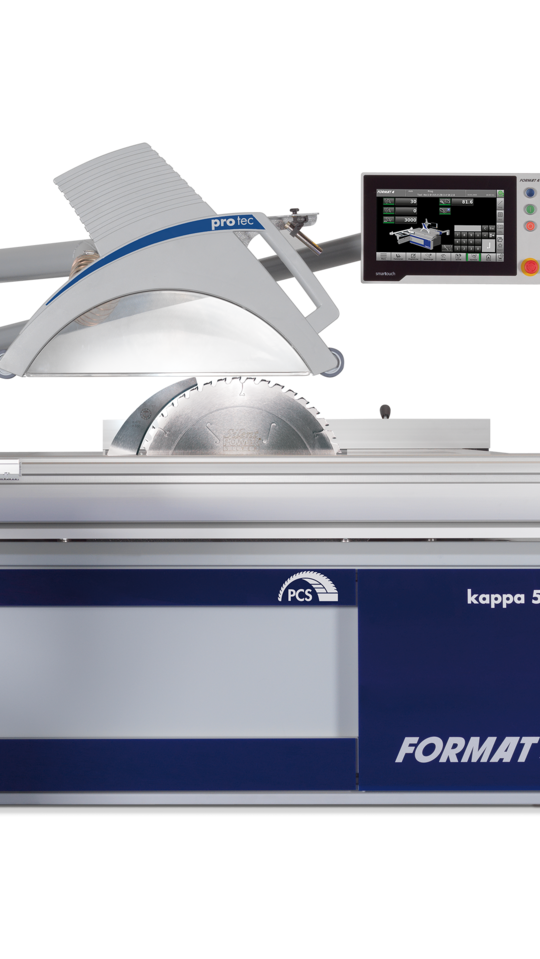

kappa automatic 100 edition

- Cutting length: 3200, 3800, 4300 mm

- Saw blade projection: 95 mm

- Variable feed speed: 1–60 m/min

- Control terminal with touch screen control

- Motor power 18 HP (13.5 kW)

With customised solutions, we raise your production to new dimensions. No matter whether in furniture making, in solid wood processing, in window construction or in plastics processing. Format4® - In a class of its own

Faster, with greater precision, more powerful and higher yields - with Format4® woodworking machines you will set new standards! You too can benefit from our know-how. By the way, Format4® is your one-stop shop for productivity solutions, woodworking machinery and software - we leave nothing to chance.

PCS®, the world's first and only non-contact safety device for sliding table panel saws highlights our competence also in terms of safety. Click here to see more.