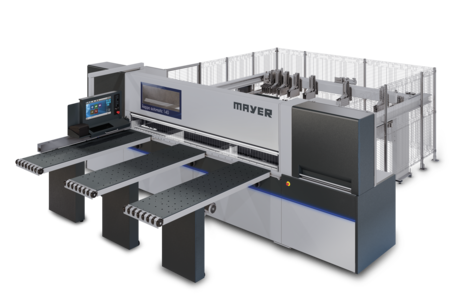

Gergaji balok tekan. Gergaji balok, horizontal kappa automatic 140

Gergaji balok MAYER. kappa automatic: kuat, presisi dan efisien dalam pemotongan.

Gergaji balok Mayer meyakinkan dengan konsep mesin yang sudah terencana dan terbukti, serta beberapa solusi mendetail, yang mencakup semua persyaratan secara singkat. Setiap tipe mesin menjadi sebuah keunggulan seutuhnya. Akan tetapi, semakin beragam persyaratan dari material yang akan dipotong, akan lebih banyak detail yang menentukan kesuksesan dari keseluruhan proses.

Dengan gergaji besar dan berat, Mayer berfokus pada kualitas ketahanan dan konstruksi permesinan kelas utama. Konsep utuh yang meyakinkan: konstruksi untuk pekerjaan berat dengan balok tekan dari baja dan pendorong material, pengoperasian sederhana bahkan ketika bekerja sendiri serta ketahanan proses yang maksimum dengan program pemotongan yang sudah dioptimalkan strukturnya secara modular serta paket peranti lunak/software baru. Semunya menjamin performa yang maksimum dan presisi dalam pemotongan panel rasional.

Software pengoptimalan pemotongan modular yang terstruktur dengan pelabelan barcode/kode batang yang mewakili ketahanan proses tertinggi. Eretan gergaji dengan gergaji utama dan gergaji scoring dipandu sepanjang sistem panduan berbentuk balok bundar yang keras dan melingkar. sistem drive rack gear dan driver gear yang sangat presisi menghasilkan sebuah gerakan yang sangat mulus dari eretan gergaji dengan kecepatan pemotongan dari 5 sampai 100 mtr/menit. Pemotongan berkelas dihasilkan melalui penyesuaian ketinggian pemotongan otomatis untuk sudut permulaan mata gergaji yang dioptimalkan dan eretan gergaji yang mulus. sistem pengukuran ganda menjamis proses pengulangan yang maksimal balok tekanan terbuka tergantung pada ketinggian material, yang mengurangi waktu gerakan material seminimal mungkin. "Paket Green Line" dengan pintu penghisap yang bisa dikontrol dan kendali langsung terhadap motor mampu mengurangi konsumsi energi sampai dengan 30%.

MAYER. Sempurna dalam hal teknis, Tepat dan Tahan Lama

Sejak 1950, pabrik mesin Otto Mayer sudah memproduksi perekat panel dan gergaji balok tekan /pressure beam saws untuk memproduksi material panel yang terbuat dari kayu, plastik, logam non-ferro dan material dasar. Pengalaman bertahun-tahun menjamin kualitas dan ketahanan dalam level tertinggi

Highlight utama secara sekilas

Variasi

Models- Keuntungan anda

Gergaji Balok Mayer untuk berbagai tantangan.

- kappa automatic 80 adalah model kelas awal Mayer untuk pemotongan panel profesional dan menjadikan standar baru pada kelas compact dari gergaji panel horizontal.

- kappa automatic 100. Lebih tangguh, lebih kuat, lebih nyaman! Gergaji balok dengan peralatan canggih, hemat energi, cepat dan sangat akurat.

- kappa automatic 120 adalah gergaji balok yang ideal untuk pemotongan yang akurat secara dimensi serta pemotongan cepat dari lembaran tunggal dan tumpukan panel.

- kappa automatic 140. Gergaji balok dengan performa maksimum untuk pemotongan cepat dan akurat. Kekuatan, kecepatan dan fleksibilitas yang mengesankan sejak pertama.

Detail

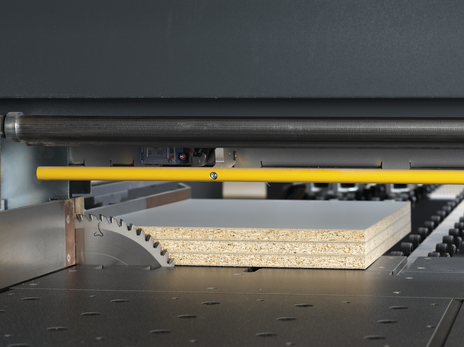

A main and scoring saw blade guarantee perfect and chip free cutting results with a cutting height of 77/100/118/139 mm. Combined with the cutting direction against the fence, a first class high end cutting result is achieved.

Desain sederhana dari panel kendali dan panduan menu untuk kendali software dengan sistem Windows yang dijabarkan dengan jelas, sangat pintar dalam pengoperasiannya. Menghubungkan kendali mesin pada sistem atau jaringan yang ada tentu saja mungkin kappa automatic bisa dilengkapi dengan software pemotongan Ardis yang dioptimalkan Sebagai pilihan, mesin ini juga dilengkapi dengan pencetak label

Unit peletakan material dilengkapi dengan 2 sistem pengukuran yang secara konstan memonitor satu sama lain. Kombinasi servomotor yang sangat presisi dan pegangan material yang solid memastikan proses berulang yang maksimum. Sistem pengukuran terpisah melalui sistem drive dan bebas dari keusangan.

Berkombinasi dengan software pengoptimalan pemotongan , sebuah label bisa dicetak untuk setiap benda kerja dengan beragam informasi (nomer pesanan, tujuan penggunaan, program CNC, sisi mana yang harus melalui mesin edging).

Pembatas veneer pneumatik tersedia untuk pemotongan panel dari material panel veneer dengan material edging terproyeksi atau panel laminasi

Trek/rel penggulung mendukung angkutan pendorong material dan memastikan pemakanan yang presisi material panel pada jalur pemotongan

Unit mesin gergaji beam saw kappa automatic memastikan pengoperasian sederhana dan efisiensi yang maksimum dengan beragam paket software.

- Modul pemrosesan bagian tepian dengan kalkulasi dimensi akhir otomatis

- Manajeman limbah dan panel

- Editor label dengan fungsi barcode dan modul gambar

- Ekspor dan Impor ASCII

- Fungsi jaringan

Dengan sensor optik langsung dibelakang garis pemotongan, panjang benda kerja bisa diukur. Hal ini menjamin proses mesin yang presisi dan mengeliminasi kebutuhan pengukuran manual yang membosankan.

kappa automatic 140

Meja mesin yang terpoles secara khusus bermanfaat ketika memproses material yang sensitif dan juga menawarkan masa guna yang tanpa batas.

Kecepatan konstan dari alat saw carriage beragam dan bisa diatur antara 5-100 mtr/menit dari panel kontrol. Sistem rack dan pinion dimana kereta berjalan memastikan kualitas pemotongan yang konstan terlepas dari material yang diproses.

Balok tekan terkontrol kappa automatic 100 tidak terbuka secara penuh ketika memproses, hanya terbuka sesuai ketinggian material, memungkinkan siklus produksi yang cepat dengan efisiensi maksimum.

Software pengoptimalan pemotongan modular menggunakan daftar material untuk mengkalkulasi proses pemotongan yang paling ekonomis dengan memperhitungkan waktu pemotongan dan jumlah limbah/sisa pemotongan. Cocok dengan kebanyakan program konstruksi dan desain, juga memungkinkan untuk mengkalkulasi jumlah material dan panjang material edging yang dibutuhkan, waktu pemotongan dan/atau terhubung dengan sistem warehouse dengan administrasi material.

Dengan meja ungkit/sistem warehouse panel menempel pada bagian belakang mesin, membuatnya mungkin untuk memuat gergaji, panel demi panel. Panel yang dibutuhkan bisa dimuat langsung dari tumpukan panel pada gergaji.

Peralatan tekan otomatis menjamin bahwa benda kerja terletak tepat pada pembatas mitre ketika pemotongan silang (lebar benda kerja 50-1200 mm)

Penjepit baja kuat, dikendalikan sistem pneumatik/angin, menjamin penjepitan yang aman dan bebas dari kerusakan untuk tumpukan panel (ketinggian bukaan 90/105/130 mm) dan panel kecil individual.

Meja bongkar muat dengan teknologi bantalan udara memastikan penanganan material yang mulus dan alur produksi yang konstan terutama ketika memproses tumpukan panel. Roda conveyor diletakkan dekat dengan pendorong material memastikan peletakan yang halus untuk material. Untuk material yang sangat sensitif terhadap tekanan, tekanan penjepitan dari klem penjepit bisa disesuaikan menggunakan manometer.

Paket Green Line tersedia untuk model kappa automatic 100, mengurangi volume penghisapan yang dibutuhkan sampai dengan 30% melalui pagar penghisapan terkontrol pada balok tekan. Sebagai tambahan, motor menggunakan energi yang lebih sedikit sampai dengan 30% dikarenakan waktu perjalanan sesudah potongan. Dengan emisi suara yang tersertifikasi hanya 73.5 dB kappa automatic 100 adalah salah satu gergaji balok paling tenang di kelasnya.

Fungsi bantalan udara diperluas mulai dari sisi meja hingga area koordinat pemotongan. Pipa udara terintegrasi pada meja baja kokoh, sehingga menjaga kualitas pemotongan tak tertandingi dan presisi yang sesungguhnya serta memfasilitasi penanganan material.

Layar lamella menutupi area di sekitar koordinat pemotongan, sehingga memperbaiki performa penghisapan dan menghalangi tersebarnya serpihan. Hal ini sangat penting ketika pemrosesan mesin untuk bahan plastik dan alumunium.

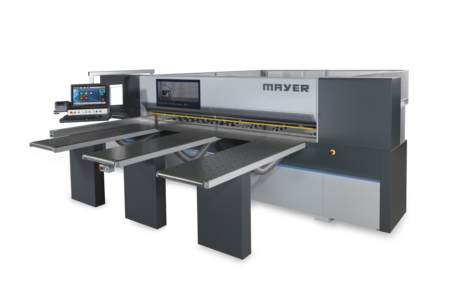

kappa automatic 120

Meja mesin yang terpoles secara khusus bermanfaat ketika memproses material yang sensitif dan juga menawarkan masa guna yang tanpa batas.

Kecepatan konstan dari alat saw carriage beragam dan bisa diatur antara 5-100 mtr/menit dari panel kontrol. Sistem rack dan pinion dimana kereta berjalan memastikan kualitas pemotongan yang konstan terlepas dari material yang diproses.

Balok tekan terkontrol kappa automatic 100 tidak terbuka secara penuh ketika memproses, hanya terbuka sesuai ketinggian material, memungkinkan siklus produksi yang cepat dengan efisiensi maksimum.

Software pengoptimalan pemotongan modular menggunakan daftar material untuk mengkalkulasi proses pemotongan yang paling ekonomis dengan memperhitungkan waktu pemotongan dan jumlah limbah/sisa pemotongan. Cocok dengan kebanyakan program konstruksi dan desain, juga memungkinkan untuk mengkalkulasi jumlah material dan panjang material edging yang dibutuhkan, waktu pemotongan dan/atau terhubung dengan sistem warehouse dengan administrasi material.

Dengan meja ungkit/sistem warehouse panel menempel pada bagian belakang mesin, membuatnya mungkin untuk memuat gergaji, panel demi panel. Panel yang dibutuhkan bisa dimuat langsung dari tumpukan panel pada gergaji.

Peralatan tekan otomatis menjamin bahwa benda kerja terletak tepat pada pembatas mitre ketika pemotongan silang (lebar benda kerja 50-1200 mm)

Penjepit baja kuat, dikendalikan sistem pneumatik/angin, menjamin penjepitan yang aman dan bebas dari kerusakan untuk tumpukan panel (ketinggian bukaan 90/105/130 mm) dan panel kecil individual.

Meja bongkar muat dengan teknologi bantalan udara memastikan penanganan material yang mulus dan alur produksi yang konstan terutama ketika memproses tumpukan panel. Roda conveyor diletakkan dekat dengan pendorong material memastikan peletakan yang halus untuk material. Untuk material yang sangat sensitif terhadap tekanan, tekanan penjepitan dari klem penjepit bisa disesuaikan menggunakan manometer.

Paket Green Line tersedia untuk model kappa automatic 100, mengurangi volume penghisapan yang dibutuhkan sampai dengan 30% melalui pagar penghisapan terkontrol pada balok tekan. Sebagai tambahan, motor menggunakan energi yang lebih sedikit sampai dengan 30% dikarenakan waktu perjalanan sesudah potongan. Dengan emisi suara yang tersertifikasi hanya 73.5 dB kappa automatic 100 adalah salah satu gergaji balok paling tenang di kelasnya.

Fungsi bantalan udara diperluas mulai dari sisi meja hingga area koordinat pemotongan. Pipa udara terintegrasi pada meja baja kokoh, sehingga menjaga kualitas pemotongan tak tertandingi dan presisi yang sesungguhnya serta memfasilitasi penanganan material.

Layar lamella menutupi area di sekitar koordinat pemotongan, sehingga memperbaiki performa penghisapan dan menghalangi tersebarnya serpihan. Hal ini sangat penting ketika pemrosesan mesin untuk bahan plastik dan alumunium.

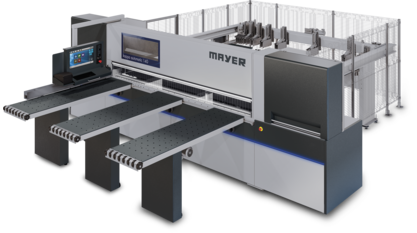

kappa automatic 100

Kecepatan konstan dari alat saw carriage beragam dan bisa diatur antara 5-100 mtr/menit dari panel kontrol. Sistem rack dan pinion dimana kereta berjalan memastikan kualitas pemotongan yang konstan terlepas dari material yang diproses.

Balok tekan terkontrol kappa automatic 100 tidak terbuka secara penuh ketika memproses, hanya terbuka sesuai ketinggian material, memungkinkan siklus produksi yang cepat dengan efisiensi maksimum.

Software pengoptimalan pemotongan modular menggunakan daftar material untuk mengkalkulasi proses pemotongan yang paling ekonomis dengan memperhitungkan waktu pemotongan dan jumlah limbah/sisa pemotongan. Cocok dengan kebanyakan program konstruksi dan desain, juga memungkinkan untuk mengkalkulasi jumlah material dan panjang material edging yang dibutuhkan, waktu pemotongan dan/atau terhubung dengan sistem warehouse dengan administrasi material.

Dengan meja ungkit/sistem warehouse panel menempel pada bagian belakang mesin, membuatnya mungkin untuk memuat gergaji, panel demi panel. Panel yang dibutuhkan bisa dimuat langsung dari tumpukan panel pada gergaji.

Peralatan tekan otomatis menjamin bahwa benda kerja terletak tepat pada pembatas mitre ketika pemotongan silang (lebar benda kerja 50-1200 mm)

Penjepit baja kuat, dikendalikan sistem pneumatik/angin, menjamin penjepitan yang aman dan bebas dari kerusakan untuk tumpukan panel (ketinggian bukaan 90/105/130 mm) dan panel kecil individual.

Meja bongkar muat dengan teknologi bantalan udara memastikan penanganan material yang mulus dan alur produksi yang konstan terutama ketika memproses tumpukan panel. Roda conveyor diletakkan dekat dengan pendorong material memastikan peletakan yang halus untuk material. Untuk material yang sangat sensitif terhadap tekanan, tekanan penjepitan dari klem penjepit bisa disesuaikan menggunakan manometer.

Meja mesin yang terpoles secara khusus bermanfaat ketika memproses material yang sensitif dan juga menawarkan masa guna yang tanpa batas.

Paket Green Line tersedia untuk model kappa automatic 100, mengurangi volume penghisapan yang dibutuhkan sampai dengan 30% melalui pagar penghisapan terkontrol pada balok tekan. Sebagai tambahan, motor menggunakan energi yang lebih sedikit sampai dengan 30% dikarenakan waktu perjalanan sesudah potongan. Dengan emisi suara yang tersertifikasi hanya 73.5 dB kappa automatic 100 adalah salah satu gergaji balok paling tenang di kelasnya.

Fungsi bantalan udara diperluas mulai dari sisi meja hingga area koordinat pemotongan. Pipa udara terintegrasi pada meja baja kokoh, sehingga menjaga kualitas pemotongan tak tertandingi dan presisi yang sesungguhnya serta memfasilitasi penanganan material.

kappa automatic 80

Eretan/kereta gergaji dengan gergaji utama dan scoring bekerja sepanjang permukaan tanah dan permukaan pemandu yang sudah dikeraskan dan memastikan gerakan yang mulus dan sudut yang tepat. Ketinggian pemotongan bisa diatur secara manual, secara pneumatik atau electromotif.

Dikendalikan secara pneumatik/angin dengan penjepit besi baja menjamin penjepitan yang aman dan bebas dari kerusakan untuk tumpukan panel (ketinggian bukaan 75 mm) dan material panel kecil individual.

Layanan Konsumen dan Pemeliharaan

Apakah Anda memiliki pertanyaan?

Showrooms

FELDER GROUP Indonesia Detail

PIKA Industrial Woodworking School

Jl. Imam Bonjol No.96

50139 Semarang, Central Java

Tel.: +62 (0) 811 296 1129

FELDER GROUP Indonesia Detail

Bellagio Mall Lantai 1 No. L2.20 Kawasan Mega Kuningan Barat Kav E4.1

Kuningan Timur Setia Budi

Jakarta Selatan 12950

Tel.: +62 (0) 811 296 1129