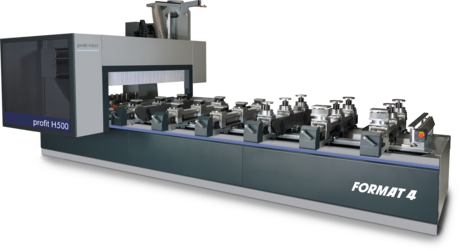

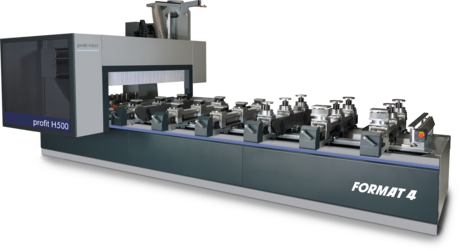

Mesin berpusat pada CNC profit H500R

Satu mesin, lima koordinat, kreatifitas tanpa batas

Workshop universal pada khususnya, dimana pemrosesan individual dari berbagai macam material semakin meningkat kepentingannya teknologi CNC 5 koordinat terbaru memastikan kreatifitas tanpa batas, dan pada saat yang sama mengurangi biaya investasi permulaan dan biaya tambahan untuk unit dan peralatan khusus. konfigurasi peralatan secara individual dan produksi yang keseluruhannya otomatis, pada level investasi yang terjangkau. Format4 profit H500 membuat masa depan pembuatan sebuah komponen menjadi keuntungan poros utama berperforma tinggi memastikan hasil yang sempurna pada setiap sudutnya, apapun materialnya Sehubungan dengan 18 poros pengeboran dan jumlah gergaji alur yang terintegrasi, profit H500 menawarkan kemungkinan pemrosesan tak terbatas dan memastikan kemungkinan siklus kerja tersingkat

dalam bentuk terbaru, desain yang permesinannya ditata ulang seutuhnya , mesin-mesin CNC dari Format4 menunjukkan kekuatan dan teknologi canggih secara sekilas.

- Tanpa selang Format4 sistem sirkuit ganda dengan tinggi pod vakum 100 mm

- 2 Z-koordinat yang dikendalikan CNC untuk siklus produksi terpendek

- s-motion: Konsol otomatis dan pemosisian pod vakum

FORMAT4 Sebuah keahlian tanpa kompromi untuk pencapaian tertinggi

Merek premium Felder Group sudah memenuhi standar tertinggi para pengguna profesional sejak 2001 Solusi modifikasi dengan performa terbaik yang tidak kenal kompromi, inovatif, menawarkan kenyamanan maksimal dalam pengoperasian dan melengkapi produktifitas.

... FORMAT4 mesin premium untuk keperluan premium

- solusi mesin yang dibuat sesuai keuangan anda

- performa tinggi yang konstan dalam pengoperasion dunia industri secara terus menerus

- solusi produksi yang dioptimalkan sesuai dengan kustomer tertentu

- design yang kuat dengan komponen premium

- Banyak variasi dari paket yang spesifik dengan solusi berteknologi tinggi

- Presisi keahliaan keteknikan yang lengkap

- kenyamanan pengguna premium

- Desain pemenang penghargaan

- Kualitas dan Ketelitian dari Austria

- Produktifitas tanpa kompromi

- Paket pelayanan yang sempurna - sebelum, selama dan sesudah pembelian

- Solusi otomatisasi

- Workshop/bengkel yang berkaitan

- Peranti lunak dan mesin-mesin dari pemasok tunggal

Detail

Vakum pods dan konsol ditentukan posisinya secara visual, cepat dan tepat dengan unit lightPos.

Lebih dari 6000 LED mengindikasikan ukuran gelas hisap, posisi, orientasi serta posisi konsol dengan ukuran sampai ke milimeter. Berkat sistem manajemen warna yang canggih, setiap tipe vakum dan orientasinya ditunjukkan dalam resolusi warna yang baik. LED RBG pada koordinat-X memberi informasi mengenai status pemrosesan. LED sepanjang koordinat X dan Y memberi gambaran visual dari posisi dan dimensi benda kerja.

Dengan lightPos, penentuan posisi benda kerja selama pergantian proses pengoperasian dapat dilaksanakan tanpa waktu pengaturan yang lama. Kenyamanan pengoperasian terbaik. Temukan lebih banyak mengenai lightPos disini.

Untuk tujuan ini, seri H200 dilengkapi dengan deretan pembatas bagian belakang dan tengah. Pada seri H300, H350 & H500, deretan setopan pada bagian depan juga tersedia sebagai pilihan. Setopan silinder solid memungkinkan referensi komponen yang fleksibel dari benda kerja yang kecil, medium dan besar di area kerja.

Akses cepat untuk mengganti bor atau pekerjaan perawatan, tudung dapat dengan mudah dibuka pada semua mesin yang menggunakan CNC.

Untuk permintaan tertinggi, semuanya termasuk, kumpulan peralatan, area pemrograman, dan panel kendali operator mesin dengan antar muka pengguna yang intuitif dan konsisten. F4®Integrate adalah software yang dikembangkan oleh Format4. Dikembangkan berdasarkan pengalaman praktis untuk penggunaan praktis bekerja sama dengan kustomer CNC kami, F4®Integrate memenuhi tuntutan tertinggi dalam permesinan CNC modern.

Nikmati kenyamanan dari interface pengguna yang canggih dan terkoordinasi dengan baik. Kumpulan peralatan (F4 Toolbox), area pemrograman (area CAM dengan area CAD yang terintegrasi, F4 Create) dan panel pengoperasian mesin (F4 Operate), semuanya dikemas dalam satu layar dengan antar muka pengguna yang intuitif dan konsisten.

Mesin F4Integrate bekerja berdasarkan G-Code, jadi program eksternal industri bisa dengan mudah terhubung dan transfer program bisa diorganisir dengan mulus.

Konsep kontrol layar sentuh intuitif dan canggih menjamin keramahan pengguna yang maksimal. Interface pengguna yang terstruktur rapi dan tampak jelas membuat anda bisa mengoperasikan mesin dengan mudah dan menjamin produktifitas maksimal. Kendali mesin ditampilkan dengan jelas secara grafis dan beberapa program, set-point dan perintah bisa dilaksanakan dengan cepat, mudah dan akurat hanya dengan satu sentuhan tombol.

Unit pengukuruan panjang otomatis menentukan panjang alat dengan akurasi 1 per 100 milimeter langsung didalam mesin. Hal ini mengeliminasi kesalahan pengukuran oleh operator mesin.

5 poros koordinat yang kuat dengan pilihan motor 12 atau 15 kW memastikan hasil yang luar biasa ketika proses milling, pengeboran dan penggergajian dari sudut manapun. Cairan pendingin khusus dan bearing keramik berkualitas tinggi memastikan presisi yang bertahan lama dan kemulusan yang luar biasa apapun materialnya. Sebuah inverter menyetel kecepatan dan bisa diatur pada kecepatan berapa pun sampai dengan 24,000 rpm.

Kepala pengebor dengan 18 poros pengeboran. 12 poros pengeboran vertikal, 32 mm jarak antara poros: Setiap poros bisa digunakan secara individual. 6 poros pengeboran horizontal, berjarak 32 mm: 4 pada koordinat X dan 2 pada koordinat Y. Setiap koordinat bisa digunakan secara individual. Pemotong slot terintegrasi pada koordinat-X. Inverted dikendalikan motor sampai dengan 7,500 rpm. Sekilas: area kerja yang lengkap bisa tercover oleh kepala pengebor untuk pengeboran vertikal dan horizontal.

Kereta agregat dengan 2 koordinat-Z memungkinkan penggunaan unit boring dan poros utama secara cepat dan bergantian. Jarak dimana koordinat-Z bisa bergerak adalah 500 mm; Hal ini memungkinkan penggunaan alat yang lebih panjang bahkan ketika pemrosesan benda kerja yang lebih tebal.

Sistem panduan X-asis: Penentuan posisi dilaksanakan dengan unit recirculating ball bearing yang bekerja pada pemandu linear yang terpoles dan diperkeras. Koordinat-X diposisikan melalui alat rack and pinion gear yang melengkung.

Sistem pemandu koordinat Y dan Z: Penentuan posisi dilaksanakan dengan unit recirculating ball bearing yang bekerja pada pemandu linear yang terpoles dan diperkeras. Koordinat Y dan Z diposisikan menggunakan alat recirculating ball spindle yang terpoles.

Pengubah alat berputar dengan posisi 24 alat dipasang pada bagian belakang outrigger dan bergerak bersama dengan outrigger sepanjang koordinat-X. Pengubah alat berputar dengan 24 posisi, membuat waktu pengubahan alat seminimal mungkin. Hal ini membuat Format4 bahkan lebih produktif!

Pengubah alat linear 12 posisi memastikan waktu pengubahan tercepat dan menawarkan ruang yang cukup untuk peralatan routing. Penutup secara optimal melindungi adaptor peralatan HSK yang berpresisi tinggi dari debu dan serpihan.

Penggerak bergerigi dan rel berkualitas tinggi mengarahkan koordinat-X dengan gerigi sudut dan berlekuk memastikan presisi yang tinggi pada kecepatan maksimum. Gir pengurang kecepatan memastikan level tinggi dari proses berulang. Bearing tertutup: recirculating ball bushing yang tahan lama dan sangat presisi yang bekerja ada pemandu linear bundar dan sudah diperkeras.

Semua koordinat berpindah secara terus menerus otomatis terlumasi memastikan perawatan yang minim, keandalan dan kesiapan pengoperasian yang konstan. Lubrikasi dikontrol rutin dan dihubungkan secara pneumatik pada titik lubrikasi pada pemandu koordinat X, Y dan Z. Siklus pelumasan diatur dengan kendali dari koordinat.

profit H500 memastikan workshop yang bersih tanpa proses pembersihan mesin yang menyita waktu. Semua bisa dilakukan dengan pemindah serpihan yang terletak pada area pengoperasian. Pembersihan bisa dikendalikan secara manual dan terletak pada sisi sebelah kiri pada mesin.

Ketersediaan permanen dari mesin produksi modern adalah faktor penting yang berpengaruh untuk produktifitas dan keuntungan dari perusahaan anda. Perawatan pencegahan yang berkelanjutan memastikan bahwa mesin anda selalu siap untuk digunakan dan menjamin presisi konstan. Dengan paket perawatan khusus kami, anda mendapat keuntungan dari produk akhir yang berkualitas tinggi dan berkelanjutan dalam jangka panjang. Sebagai tambahan pada perawatan mesin secara lengkap, semua komponen mekanis, pneumatik dan elektrik juga fitur keamanan akan diperiksa. Anda mendapatkan keuntungan dari Layanan Pelanggan gratis dan akan menerima penawaran spesial pada software pelatihan dan suku cadang. Dapatkan perawatan khusus anda sekarang dan pastikan hasil yang sempurna untuk tahun-tahun yang akan datang.

Variasi bentuk vakum pod menjamin penentuan posisi yang aman dari benda kerja dengan bentuk apa pun. Sebagai tambahan, jumlah bantalan penghisap vakum dan peralatan klemping bisa digunakan secara fleksibel pada keseluruhan konsol tanpa batasan.

Pada konfigurasi standar, benda kerja, pendukung benda kerja dan bantalan penghisap vakum ditampilkan secara simultan pada papan CNC. Hal ini menjamin bahwa benda kerja diposisikan secara aman dan tidak ada benturan antara peralatan dan vacuum pod. Posisi yang pasti dari vacuum pod pada konsol ditunjukkan secara akurat menggunakan laser.

Sistem lightPos tersedia sebagai tambahan pada alat penentu posisi standar milik kami.

Sebuah deflektor serpihan kayu dipasang pada poros yang dikendalikan oleh koordinat-C yang memungkinkan penggunaan tanpa batas dari peralatan yang ada. Ketika memproses edging dengan mesin , debu dan serpihan langsung terarah pada porta penghisap.

Posisi tudung penghisap memposisikan dirinya sendiri secara otomatis terhadap ketinggian benda kerja sehingga secara signifikan mengurangi emisi debu dan suara.

profit H500 16.38

X= 3740 mm

Y= 1505 mm

Z= 350 mm

(ketinggian saluran dari ketinggian konsol)

profit H500 16.56

X= 5540 mm

Y= 1505 mm

Z= 350 mm

(ketinggian saluran dari ketinggian konsol).

Warna yang berubah dari sistem lampu yang inovatif menampilkan status mesin yang bervariasi. Hal ini memungkinkan untuk tetap terinformasi mengenai status terbaru dari mesin profit berCNC anda.

Simulator 3D memungkinkan waktu proses dengan mesin yang akurat untuk dikalkulasi dan representasi jarak dari jarak perjalanan, kecepatan rata-rata pemakanan, ketinggian berlebih dan perlengkapan pilihan seperti unit 5-motion, deflektor serpihan kayu, pengubah alat berputar dan kepala bor. Uji tes benturan menguji apakah ada benturan yang mungkin terjadi dan memastikan keamanan kerja pada mesin. Melalui alokasi peralatan pada profil DXF, kontur dari router bisa ditunjukkan pada benda kerja. Bahkan saat kalibrasi peralatan baru, profil DXF bisa digunakan untuk menolong mengurangi jumlah penggunaan material.

Konsol "s-motion" yang otomatis sepenuhnya membuat anda bisa secara komplit memproses komponen pintu dan jendela secara sangat cepat dan dengan kualitas terbaik.

Dimodifikasi sesuai kebutuhan, area kerja bisa diperlengkapi dengan 6 atau 8 konsol. Pilih antara 2 sistem konsol yang sudah diuji coba dengan level otomatisasi yang berbeda, memastikan anda mempunyai pengaturan yang sempurna untuk benda kerja yang berbeda ukuran dan desain.

Tambahan pada setopan silinder benda kerja; Setopan terpisah tersedia untuk membantu dalam pemrosesan permukaan veneer dengan sebuah veneer atau laminate yang tergantung.

Jika tudung dalam posisi parkir, keseluruhan area kerja bisa diakses dengan bebas Maka dari itu, operator mesin mempunyai akses bebas selama peletakkan benda kerja

Pada bagian depan mesin, palang sakelar kaki terintegrasi pada alas yang berada di keseluruhan panjang area kerja. Hal ini mengeliminasi kebutuhan untuk mencari atau memindahkan pedal kaki selama pencarian posisi benda kerja. Konstruksi sederhana yang menyatu dengan desain mesin yang koheren.

Apapun itu, mesin hanya akan digunakan untuk pembuatan kabinet atau untuk pembuatan apa saja, anda bisa memutuskan mana konfigurasi kepala pengebor yang cocok untuk anda. Pilihlah antara, kepala pengebor dengan poros pengebor dengan poros vertikal atau dengan poros dan gergaji grooving untuk pemrosesan vertikal dan horizontal. Inverter dikendalikan motor sampai dengan 7,500 rpm

Layanan Konsumen dan Pemeliharaan

Apakah Anda memiliki pertanyaan?

Showrooms

FELDER GROUP Indonesia Detail

PIKA Industrial Woodworking School

Jl. Imam Bonjol No.96

50139 Semarang, Central Java

Tel.: +62 (0) 811 296 1129

FELDER GROUP Indonesia Detail

Bellagio Mall Lantai 1 No. L2.20 Kawasan Mega Kuningan Barat Kav E4.1

Kuningan Timur Setia Budi

Jakarta Selatan 12950

Tel.: +62 (0) 811 296 1129