Combination Machine C3 31

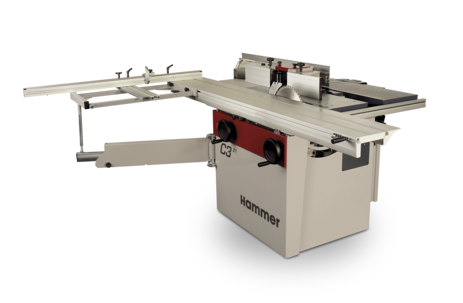

Compact dimensions without sacrificing performance and versatility!

A limited work space does not have to mean that what you can expect from a combined machine is also “limited”. Quite on the contrary, your Hammer C3 31 combination machine satisfies the greatest demands, in the smallest space with perfect results.

Modern machine technology permits fast adjustment work, be it when planing, sawing, moulding or mortising.

The sensational value for money, the “user-friendliness”, versatility and precision cannot be beaten in this class, see for yourself.

We have taken the features that have been most popular with our customers over the years and consolidated them into the Comfort Feature Package, which is now available at an amazing price.

For mortising you can, as an option, equip your Hammer with the horizontal mortiser.

Hammer. Affordable functionality and reliability

Since 1997 Hammer has been producing high quality yet affordable woodworking machines for do-it-yourselfers and small businesses. Robust, durable, space-saving and precise in its operation. Quality products that simply make woodworking fun.

The most important highlights at a glance

Variants

Models- Your benefits

... why you should choose a Hammer

- Excellent value for money

- Decision making reliability for many years to come

- Innovative machine technology

- Solid cast iron tables and units

- High quality, unique detail solutions as part of the standard package

- Top quality manufacturing with strict quality guidelines

- Remarkably user friendly

- Classic design

- Quality and precision from Austria

- Compact functionality

- Mobile as an option

- Minimal space requirement

- Quickest changeover times

Details

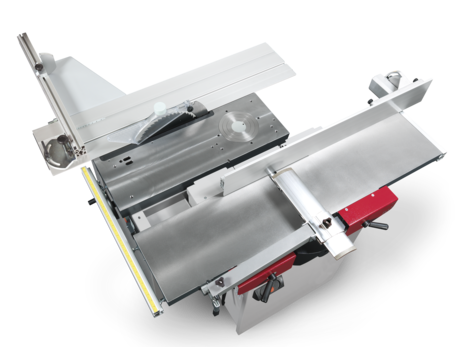

The cutting width on the saw table can be adjusted to any position between 0 and 600 mm. The scale that is integrated into the rail ensures the exact setting of the aluminium rip fence to the position required. The aluminium fence can be positioned in any position along the cutting direction - when processing long workpieces you get a better feed of the workpiece and ensure a high processing precision. When carrying out mitre cuts with a tilted saw blade it is possible to move the fence from the horizontal to the flat position. The narrow fence edge then enables the rip cutting of very thin workpieces. An even more precise, tenth of a millimetre accurate setting of the aluminium rip fence can be achieved with the optional Hammer fine adjustment.

The Hammer 3 knife quick-change, self-setting cutterblock system guarantees excellent planed wood surfaces and simple operating comfort. Since 1987 the cutterblock quick-change system has proven itself a thousand times over and our customers worldwide have saved on expensive additional investment in standard planer cutterblocks. The quick-change cutterblock system is only available from the Felder Group! Your advantages at a glance:

- Planer knife change without adjustments in seconds

- Disposable knives, each with two cutting edges at an affordable price

- no expensive adjustment devices required as with the standard planer knives for example

- no second set of planing knives are required during the sharpening cycle

Exclusive for planer/thicknessers from the Felder Group. The Silent-Power® spiral cutterblock reduces noise emissions by more than half when planing. The continuous pulling cut ensures tear-free results when planing all types of wood. With this revolutionary new development from Felder you are obtaining all of the advantages of a spiral cutterblock at considerably lower operating, investment and adjustment costs. The advantages of the Silent-Power® cutterblock at a glance ...

- Sensationally quiet, noise emissions halved

- Blade life up to 20 times longer

- Four highly precise cutting edges on each knife

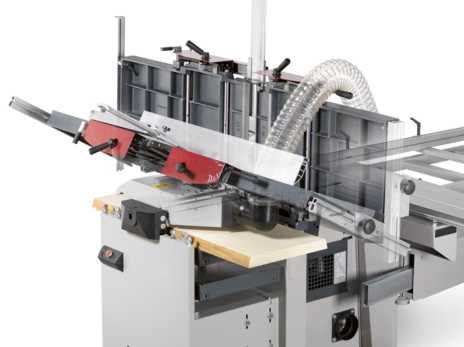

The horizontal mortiser is mounted on the planer side.

Professional equipment: “220” spindle fence for max. tooling diameter 220 mm, MULTI adjustment system for spindle fence “220” enabling parallel alignment and quick setup

C3 31

C3 31 comfort

C3 31 perform

Technology Data

Electrics

Surface Planer and Cutterblock

Thickness planer unit

Saw Unit

Spindle Moulder Unit and Spindle Fence

Anodised Format Sliding Table

Outrigger Tables and Crosscut Fences

Mortising Unit

Weight

Important Accessories

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP UK Ltd. Details

Unit 2 Sovereign Business Park, Joplin Court, Crown Hill

MK8 0JP MILTON KEYNES

Tel.: 01908 635000

Business Hours Monday to Friday 09.00 to 17.00

Felder Group Scotland Details

Unit 4 Lindsay Square, Deans Industrial Estate

EH54 8RL Livingston

Tel.: 01506 342250

Business Hours please call for an appointment