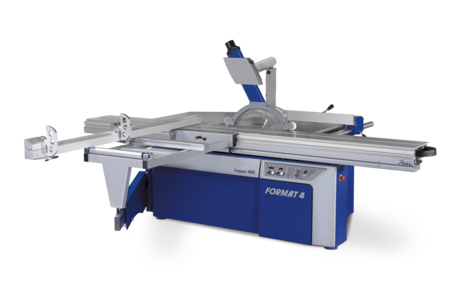

Sliding Table Panel Saw kappa 400

Convincing in all areas

The Format4 sliding table saws reflect at first glance the strive for perfection and the courage to find new solutions.

The machine's housing with its dynamic design conceals advanced technology and exemplary operating comfort! For you, this means simple and convenient operation at the highest level of work safety.

The Format4 kappa 400 is outstanding in all areas. In addition to a good price-performance ratio, the sliding table saw impresses with its 3-axis control, heavy-duty circular saw unit, sliding table, ease of use and precision.

x-motion: CNC power unit control with 5.7" (145 mm) LCD screen on overhead control panel.

The c-tech product line offers specially designed equipment options for processing plastics and composite materials.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

Variants

Models- Your benefits

... FORMAT4 Premium machines for premium requirements

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Tailor made financing solutions

Details

- Electronic height adjustment with LED display

- Electronic angle adjustment with digital LED display

- Tilting of saw-blade 90°-45°

- Oversized saw arbor with double trunnions

- Maximum motor power transfer from the Poly-V belt

- 3-speed: 3500/4500/5500 rpm

- Optimal dust extraction with the completely enclosed, below table extraction system

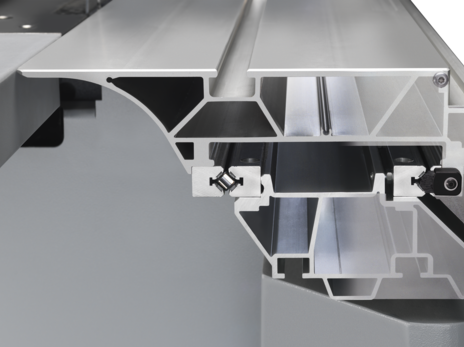

- Dovetail guidance system for height adjustment

- A highly robust synthetic material located in the guidance track of the tilting brackets, ensures they run smoothly and maintenance free even under the most extreme conditions. The tilt guide segment runs without lubrication and is insensitive to dust.

- Precise double trunnion system

- High load-bearing capacity and operating life

- Play free tilt

- Unaffected by dust

- Completely maintenance free

- No lubrication required

- 6 year guarantee

- Tilting of saw-blade 0°-45°

- 5” (133 mm) of cutting height at 90 degrees

- 4” (94 mm) of cutting height at 45 degrees

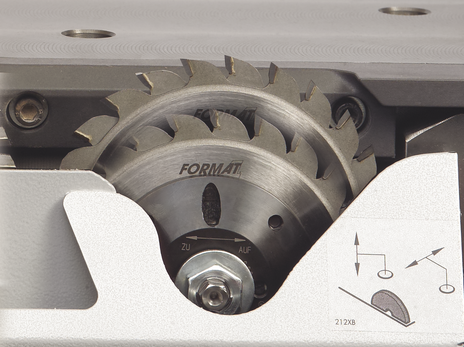

The kappa 400 has dado capability. Used with the massive specially designed Format4 dado cutter head clean, precise dado cuts from 1/4”–3/4” (6–20 mm) are guaranteed.

An alternative to the worldwide unique Format4 saw blade quick change system "Easy-lock" is now the "Quick-lock" clamping system, which with the use of just one tool makes it quick and easy to change the saw blade.

The integrated guide rollers of the outrigger table ensure an incredibly smooth operation upon maximum load capacity. The bearing rail is moved along a “X-Roll” guide and is fast and micro-adjustable. The LED display enables you to set the required angle to one tenth of a degree. The fence can be tilted to any position between -45° and +45° and guarantees precise mitre cuts.

The new and solidly built parallelogram outrigger table enables infinitely variable miter cuts from -46° up to +46°. The surface available for the workpiece remains the same regardless of the angle setting. The digital display of the angle setting is accurate to 1/100th of a degree. The angle/length compensation is carried out using either a Nonius scale or “digi-compensation plus”

On request, we’ll equip your Format4 with the digital telescopic fence. Below, you see the cleverly integrated electronic digital scale with values correct to 4/1000” (0.1 mm). Additional functions, for example the setting of successive measurements, make your daily working life easier.

For the processing of non-ferrous metals, your Format4 can be fitted with spraying equipment. This enables high performance lubricating oil to be sprayed directly onto the sawblade.

kappa 400 x-motion

kappa 400

The rip fence can be fitted with an electronic digital-display. The perfect integration of the electronic unit allows you to turn the display around 90°, so the values are clearly and exactly readable from the operating area. Additional functions such as the input of successive measurements make your daily working life easier. Further highlights:

- Bright, easy to read LED display

- No batteries are required due to a direct connection to the machine's power supply

- Automatic recognition of vertical or horizontal fence position

- Measurement compensation of the saw blade tooth width

Technical data

Electrics

Saw unit

Scoring Unit

Control Systems

Cutting width and rip fence

Sliding tables anodized, “X-Roll” guiding system

Outrigger table and crosscut fence

General

Packaging

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP USA Headquarters Details

USA Headquarters | New Castle, Delaware Showroom

2 Lukens Drive, Suite 100-400

New Castle, DE 19720

Tel.: 866-792-5288

Fax: 302-322-9865

Business Hours: Mo. – Fr. | 8am – 5pm (EST)

FELDER GROUP USA Dallas Details

South Division | Dallas, Texas Showroom

1420 Halsey Way / Suite 100

Carrollton, TX 75007

Tel.: 866-792-5288

Business Hours: Mo. – Fr. | 8am – 5pm (CST)

FELDER GROUP USA West Sacramento Details

West Division | West Sacramento, California Showroom

1747 Enterprise Blvd.

West Sacramento, CA 95691

Tel.: 866-792-5288

Fax: 916-375-3194

Business Hours: Mo. – Fr. | 8am – 5pm (PST)

FELDER GROUP USA Anaheim Details

West Division | Anaheim, California Showroom

3531 E. Miraloma Ave., Unit 1

Anaheim, CA 92806

Tel.: 866-792-5288

Business Hours: Mo. – Fr. | 8am – 5pm (PST)

FELDER GROUP USA Denver Details

West Division | Denver, Colorado

Tel.: 866-792-5288

Business Hours: On appointment