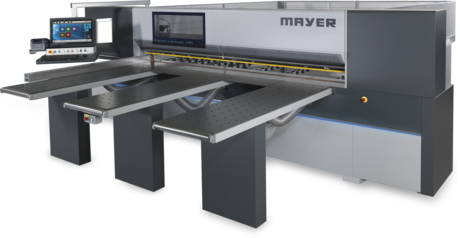

Pressure beam saw | Beam saw, horizontal kappa automatic 100

MAYER Beam Saws kappa automatic: Powerful, precise & efficient in cutting

Mayer beam saws convince with the proven, well-thought-out machine concept and numerous detailed solutions, which puts every requirement exactly in a nutshell. Each machine type stands for absolute excellence. However, the more diverse the requirements of the materials to be cut, the more it is the small details that determine the success of the entire process.

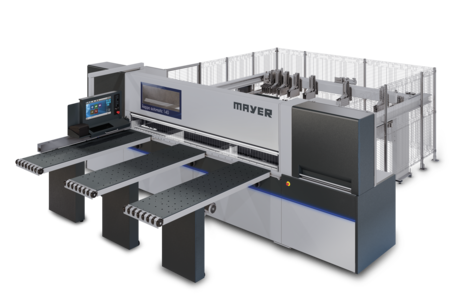

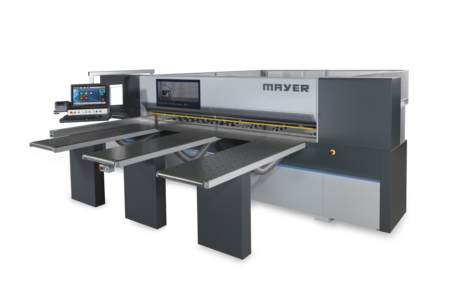

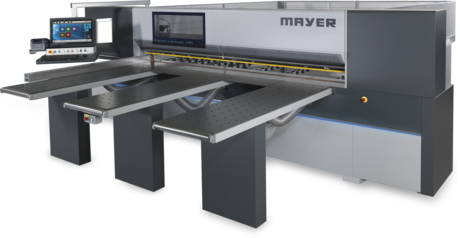

With its solid, heavy-duty saws, Mayer focuses on durable quality and first-class machine construction. It is also the full concept that convinces: The heavy-duty construction with steel pressure beam and material pusher, the simple operation even when working alone and maximum process reliability with the modularly structured cutting optimisation program as well as a new software package all guarantee maximum performance and precision in rational panel cutting.

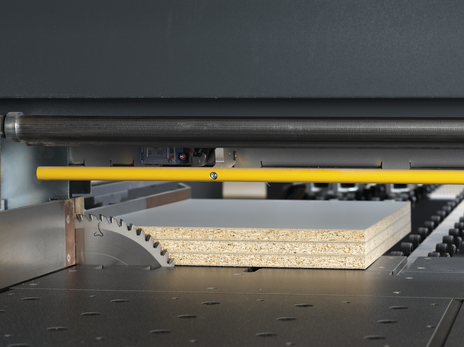

The modular structured cutting optimisation software with barcode labelling represents highest process reliability. The saw carriage with main and scoring blade is guided along a hardened and ground round bar guide system. A highly precise gear drive and gear rack drive system results in an extremely smooth movement of the saw carriage with cutting speeds from 5 to 100 m/min. The high-end cutting edges are achieved by the automatic cutting height adjustment for the optimum saw blade entry angle and the smooth running of the saw carriage. The dual measuring system guarantees maximum repeatability. The pressure bar opens depending on the material height, which reduces the material movement times to a minimum. The "Green Line package" with its controlled extraction gates and direct control of the motors can reduce energy consumption by up to 30%.

MAYER. Technically perfect, precise and durable

The Otto Mayer machine factory has been producing panel-sizing and pressure beam saws for processing panel materials made of wood, plastics, non-ferrous metals and basic materials since 1950. The many years of experience guarantee quality and reliability at the highest level.

The most important highlights at a glance

Variants

Models- Your benefits

A Mayer Beam Saw for every challenge

- The kappa automatic 80 is the Mayer entry-level model for professional panel cutting and sets new standards in the compact class of horizontal panel saws.

- kappa automatic 100. More strength, more power, more comfort! The beam saw with sophisticated equipment - energy-efficient, fast and absolutely accurate.

- The kappa automatic 120 is the ideal beam saw for quick and dimensionally accurate cutting of single sheets and panel stacks.

- kappa automatic 140 – The beam saw with maximum performance for fast and accurate cutting. Power, speed and flexibility impress right away.

Details

A main and scoring saw blade guarantee perfect and chip free cutting results with a cutting height of 77/100/118/139 mm. Combined with the cutting direction against the fence, a first class high end cutting result is achieved.

The kappa automatic beam saw, guarantees simple operation and maximum efficiency with numerous software packages.

- Edge processing module with automatic final dimension calculation

- Panel and waste management

- Label editor with barcode function and picture module

- ASCII-Export and Import

- Network function

With an optical sensor directly behind the cutting line, the length of the workpiece is measured. This guarantees precise machining and eliminates the need for tedious manual measurements.

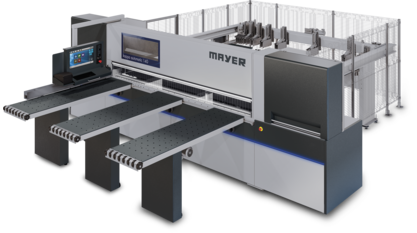

kappa automatic 140

The controlled kappa automatic pressure bar does not open completely whilst processing, but instead only by the height of the material, enabling quick production cycles with maximum efficiency.

Solid steel clamps, pneumatically controlled, guarantee a safe and damage-free clamping of panel stacks (opening height 90/105/130 mm) and individual small panels.

The Green Line Package available for the kappa automatic models reduces the extraction volume required by up to 30% through a controlled extraction gate on the pressure bar. Additionally the motors use up to 30% less energy due to the reduced travel time after the cut. With a certified noise emission of only 73.5 dB the kappa automatic is one of the quietest beam saws in its class.

The air cushion function is extended from the side tables to the area of the cutting axis. The air nozzles are integrated into the solid steel table, thus maintaining absolute precision and unparalleled cutting quality as well as facilitating material handling.

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

kappa automatic 120

The controlled kappa automatic pressure bar does not open completely whilst processing, but instead only by the height of the material, enabling quick production cycles with maximum efficiency.

Solid steel clamps, pneumatically controlled, guarantee a safe and damage-free clamping of panel stacks (opening height 90/105/130 mm) and individual small panels.

The Green Line Package available for the kappa automatic models reduces the extraction volume required by up to 30% through a controlled extraction gate on the pressure bar. Additionally the motors use up to 30% less energy due to the reduced travel time after the cut. With a certified noise emission of only 73.5 dB the kappa automatic is one of the quietest beam saws in its class.

The air cushion function is extended from the side tables to the area of the cutting axis. The air nozzles are integrated into the solid steel table, thus maintaining absolute precision and unparalleled cutting quality as well as facilitating material handling.

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

kappa automatic 100

The controlled kappa automatic pressure bar does not open completely whilst processing, but instead only by the height of the material, enabling quick production cycles with maximum efficiency.

Solid steel clamps, pneumatically controlled, guarantee a safe and damage-free clamping of panel stacks (opening height 90/105/130 mm) and individual small panels.

The Green Line Package available for the kappa automatic models reduces the extraction volume required by up to 30% through a controlled extraction gate on the pressure bar. Additionally the motors use up to 30% less energy due to the reduced travel time after the cut. With a certified noise emission of only 73.5 dB the kappa automatic is one of the quietest beam saws in its class.

The air cushion function is extended from the side tables to the area of the cutting axis. The air nozzles are integrated into the solid steel table, thus maintaining absolute precision and unparalleled cutting quality as well as facilitating material handling.

kappa automatic 80

Solid steel clamps, pneumatically controlled, guarantee a safe and damage-free clamping of panel stacks (opening height 2⅞" (75 mm)) and individual small panels.

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP USA Headquarters Details

USA Headquarters | New Castle, Delaware Showroom

2 Lukens Drive, Suite 100-400

New Castle, DE 19720

Tel.: 866-792-5288

Fax: 302-322-9865

Business Hours: Mo. – Fr. | 8am – 5pm (EST)

FELDER GROUP USA Dallas Details

South Division | Dallas, Texas Showroom

1420 Halsey Way / Suite 100

Carrollton, TX 75007

Tel.: 866-792-5288

Business Hours: Mo. – Fr. | 8am – 5pm (CST)

FELDER GROUP USA West Sacramento Details

West Division | West Sacramento, California Showroom

1747 Enterprise Blvd.

West Sacramento, CA 95691

Tel.: 866-792-5288

Fax: 916-375-3194

Business Hours: Mo. – Fr. | 8am – 5pm (PST)

FELDER GROUP USA Anaheim Details

West Division | Anaheim, California Showroom

3531 E. Miraloma Ave., Unit 1

Anaheim, CA 92806

Tel.: 866-792-5288

Business Hours: Mo. – Fr. | 8am – 5pm (PST)

FELDER GROUP USA Denver Details

West Division | Denver, Colorado

Tel.: 866-792-5288

Business Hours: On appointment