Thicknesser D 951

These machines will provide you with more precision and quality than you could ever imagine from a thicknesser.For decades the Felder system with double sided disposable planer knives has proved its worth. Precisely manufactured and adjusted at the factory, there is no need to adjust the planer knives after installation. No expensive adjusting tools have to be purchased.

It’s fast and easy to change the planer knives. In less than a few minutes you can change all knives in either the 4-knife cutterblock. Felder planer knives are set and ready to use.

... with “Power-Drive” it is all electric

Turn the control knob for quick adjustment, and push the button for fine adjustment. The LED display clearly shows the actual value.

... with “Digi-Drive” simply type it in

Enter the required dimension, press Start and the thicknesser table will move precisely to the required position. Set and actual values are displayed on LED displays. Additional optional functions, such as incremental position and four programmable thicknesser table positions are available.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

The solid cast iron cutterblock housing is built for heavy duty work. We can also provide rubber outfeed rollers as an option. The pressure beams combined with the rubber feed roller serve to machine simultaneously workpieces of differing width.

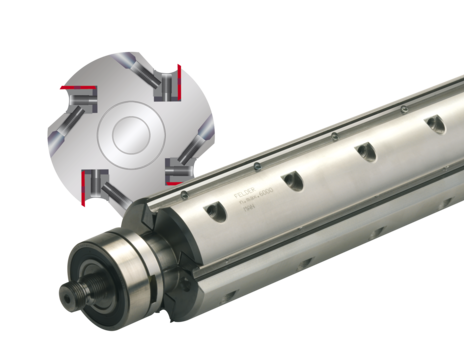

Exclusive for planer/thicknessers from the Felder Group. The Silent-Power® spiral cutterblock reduces noise emissions by more than half when planing. The continuous pulling cut ensures tear-free results when planing all types of wood. With this revolutionary new development from Format4 you are obtaining all of the advantages of a spiral cutterblock at considerably lower operating, investment and adjustment costs. The advantages of the Silent-Power® cutterblock at a glance ...

- Extremely quiet, noise is reduced by half

- Usable blade life twenty times longer than standard blades

- Four highly precise cutting edges on each knife

- Optimised chip extraction and reduced chip volume

- Tear-free planing results

- Reduced power consumption when compared to similar systems

Technology Data

Electrical setup

Cutterblock

Thickness Planer and Feed Drive

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

Gumaco Gulf Machines Trading Est. Headquarter Details

Exit 18, New Al Kharj Road PO Box 317009

11331 Riyadh, Kingdom of Saudi Arabia

Tel.: +966 11 242 6911 | +966 56 063 5894

Fax: +966 1242 6933

Gumaco Gulf Machines Trading Est. Details

Al jubail - Dahran express way Al Fayha’a district

22243 Dammam , Saudi Arabia

Tel.: +966 56 950 1967