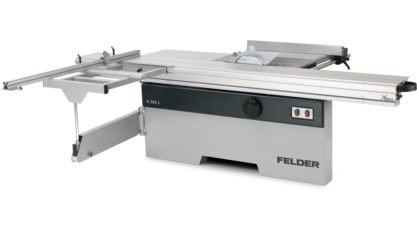

Sliding Table Panel Saw K 500 S

K 500 S - the “small” Panel Saw from FELDER

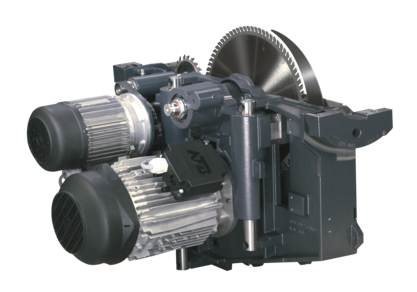

Do not be fooled by the inconspicuous exterior of the FELDER K 500 S. The sliding table saw is a true power pack, despite its size. With the innovative, tilting saw blade unit and precision double guiding for precise angle and height adjustment, the K500 S guarantees a new dimension of efficiency. The built-in, electrically operated scoring saw blade with a Ø of 120 mm makes cuts even through materials with sensitive surfaces a breeze. At the heart of the FELDER K 500 S, the powerful circular saw unit a circular saw shaft, which allows a saw blade with up to Ø 315 mm while using of the scoring unit. A ten year guarantee on the "X-Roll" sliding table, highest manufacturing quality and strict FELDER production standards make this sliding table panel saw reliable partner for many years to come.

- Efficiency meets ease of use: 104 mm cutting height with a saw blade diameter of 315 mm

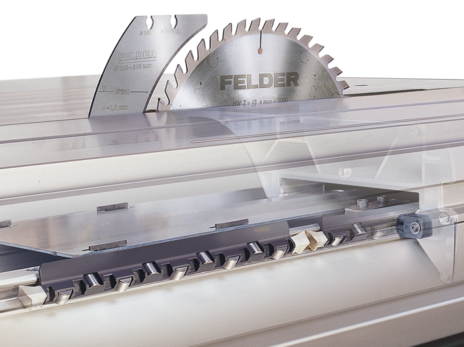

- Combined use of an electric Ø 120 mm scoring unit with a Ø 315 mm main saw blade

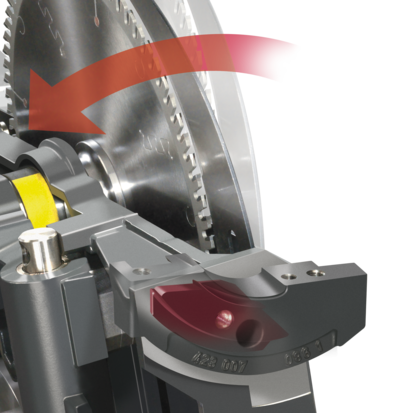

- "Easy-Glide" tilting segment guide with 6 year guarantee

- Patented "X-Roll" sliding table with 10 year guarantee

- Cutting length 2500–3200 mm

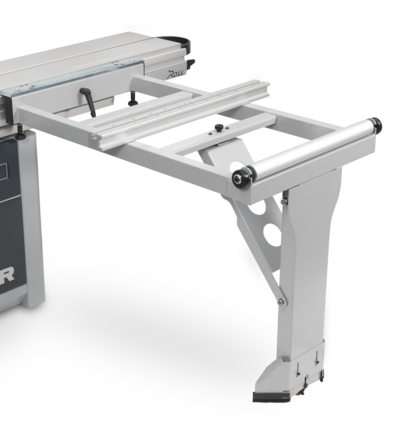

- Operating smoothness and precision even when under maximum load: large dimensioned, solid outrigger 1300

- Outrigger crosscut fence 2600 mm (1300 or 3200 mm optional)

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

The enhanced circular saw unit with the patented tilt segment "Easy-Glide" enables the combination of a main saw blade with a Ø from 250 mm to Ø 315 mm and a Ø 120 mm scoring unit.

The electrically driven Ø 120 mm scoring saw blade ensures tear-free cuts and is perfect for materials with a surface that easily tears off. The scoring saw blade can be adjusted in height without clearance by means of easily accessible adjusting screws.

- For rip and formatting cuts of large panel material

- Floor guides are height adjustable, 4.5 m in length, consists of 3 sections

Technology Data

Electrical setup

Saw and Scoring Unit

Sliding Tables

Outrigger Tables and Crosscut Fences

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

Sicar-Yu D.O.O. / StilLes Group D.O.O. Details

Koci Ivana 6a

21000 Novi Sad

Tel.: +381 21 6800 942