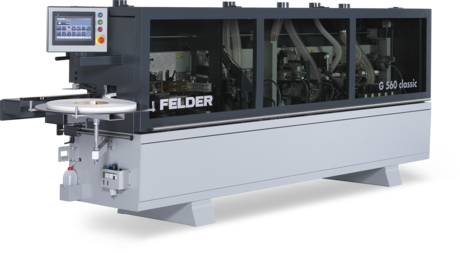

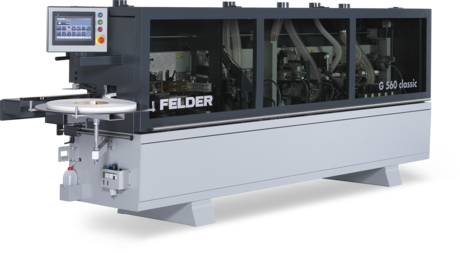

Edgebander G 560 classic

Perfect workpieces in a single work step

Intuitive operation via touchscreen, greater flexibility and productivity with the new interchangeable glue pots, and ultimately a perfect finish - both Felder edgebanders, G 560 classic and G 580 classic, boost the quality of production when it comes to processing a wide variety of coiled and strip materials for edge thicknesses of up to ¹³/₆₄" (5 mm).

Perfect workpieces in a single work step - the two Felder classic models are machines of high quality engineering. In addition to the standard equipment, the G 580 classic features a premilling and a corner rounding unit to satisfy the most demanding requirements of professional woodworkers.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Variants

Models- Your benefits

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Powerful and efficient

- Complete package: Comprehensive service support

Details

The individual machine units can be switched on and off easily from the clearly laid out control panel.

- Glue temperature settings

- Automatic glue temperature reduction

- The units can be switched on and off

- Odometer for amount of material used

- Display of the maintenance intervals

- Plain text error messages

Solid chain feed equipped with click pads. A round and a flat guide system move the workpieces through the machining units precisely and without tipping. A feed speed of 9 m/min (10.8 m/min with 60Hz) ensures short working cycles and maximum productivity.

Adjustment to the respective panel thickness of 8 to 50 mm is done quickly and precisely using the handwheel and the readout display. The diagonally arranged ball-bearing pressure rollers guarantee optimum hold and precise guiding of the workpieces

Two counter rotating, activation controlled premillers with diamond tipped spiral cutters ensure first class edges to which the material is to be applied. With the premilling unit you will achieve splinter-free edges when processing laminated material. Depth of cut is continuously adjustable from 0 to 2 mm.

Coiled materials of 0.4 to 3mm in thickness and solid wood edge strips of 5 mm thickness can be processed in single feed with an edge height of 14 to 50 mm. The processing of strip materials is possible in single feed. The synchronised, mechanical edge feed ensures an optimal feed of the material.

The activation controlled, high-quality infrared quartz heating lamp heats the edge surface before the panel reaches the glueing unit ensuring maximum process reliability of the edge adhesion, especially with cold workpieces.

The Teflon-coated changeable gluepot can be quickly and easily replaced and holds 1.5 kg of adhesive granulate. The machine is ready for use after a brief heat-up time. The micro adjustable glue roller ensures the correct dosage of the hot-melt adhesive and allows perfect matching to different edge materials.

The quick and easy change to other adhesive colours and the use of PUR glue guarantee productive procedures and excellent edges for all areas of application.

The edging material is pressed cleanly, perfectly evenly and precisely onto the workpiece by the large, power-driven first roller. The two subsequent conical pressure rollers provide additional pressure on the top and bottom of the workpiece, creating a perfectly even bond between the edging material and the workpiece.

The end trimming unit consists of two independent saw trimming units with high frequency motors (12,000 rpm). Linear guides ensure maximum precision. The trimming units can be manually tilted from 0° - 10°.

Adjustment of the settings for flush, radius and bevel trimming of thin edges is quick and easy. The newly developed adjustment system removes edge thickness tolerances and prevents any wrong adjustments. Two independent high frequency motors with special cutters ensure a perfect finish on all types of edge material. By default, the machine is equipped with 2 mm radius tools. Optionally, the unit can be equipped with a universal router, which allows the processing of 1 mm and 2 mm radii as well as flush trimming up to 5 mm edge thickness.

A gentle pulling cut removes any traces of radius milling, creating a perfectly smooth "finish". Fine adjustment is done manually.

For a perfect workpiece surface "finish". The light scraping function of the surface scraper knives removes all glue residue from the glue joint on the workpiece surface. One more step towards the perfect and completely finished workpiece.

The unit is made up of two independent electric motors, which are equipped with cotton buffers. The task of the buffing unit is to clean and polish the top and bottom part of the edge. Super finish for ABS and PVC edging material. The machine can, on request, be equipped with spraying equipment to apply polish onto the workpiece.

Low consumption in the case of fragile edging materials thanks to controlled spray jets and the application of release agents for PUR adhesives and lubricants. Cleaning and buffing agents keep workpieces clean and ensure a perfect finish without the need for any refinishing.

G 580 classic

No time consuming post processing of the workpiece! The G 580 classic corner rounding unit handles the "finish" of workpiece corners (including soft-forming or post-forming materials) for edge material from 0.4 to 3.0 mm and a processing height of 50 mm at an infeed rate of 9 m/min. The solid construction as well as the linear guides and TC routers with start-up coupling ensure long-lasting precision. Control of the corner rounding unit via touchscreen.

Customer service & maintenance

Do you have any questions?

Showrooms

Issa Group International Details

Khiljan Street, George Issa Bldg

Fanar

Tel.: Mobile +961 716 000 22

Fax: +961 369 3313 108