Thicknesser exact 51

Precision and comfort for heavy use.

When precision and perfectly thicknessed results are what you require, you need not look any further than the Format4 Thicknesser. Technically superior, simple to operate and built to last. These are the standard qualities in each and every Format4 Thicknesser. Imagine your perfect thicknesser and then find it with Format4!

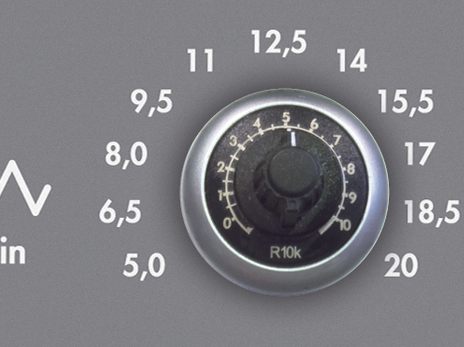

Additional to the high class standard specification, such as the spring loaded segmented outfeed pressure bar and variable speed adjustment of between 5 and 20 m/min, the new exact 51 with its long list of optional specifications can be equipped to the exact specification that the customer requires. Wood is a living material and regardless of which type of wood, regardless of moisture content and of the country specific method in which wood is to be thicknessed – we have the perfect solution for you. With options including a segmented infeed roller, rubber coated rollers as well as below table rollers and much more, the new Format4 exact 51 also comes at an incredibly attractive price.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

... FORMAT4 Premium machines for premium requirements

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Tailor made financing solutions

Details

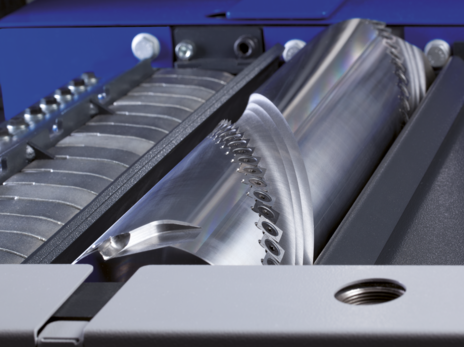

The thicknesser with the Format4 System cutterblock, 120 mm knife flight and 4 knives delivers performance, precision and user-friendliness all-in-one.

The solid cast iron cutterblock housing is built for heavy duty work. We can also provide rubber outfeed rollers as an option. The pressure beams combined with the rubber feed roller serve to machine simultaneously workpieces of differing width.

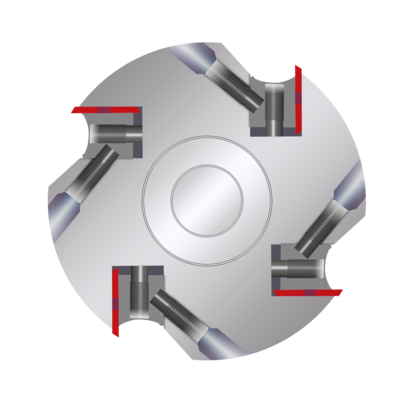

Exclusive for planer/thicknessers from the Felder Group. The Silent-Power® spiral cutterblock reduces noise emissions by more than half when planing. The continuous pulling cut ensures tear-free results when planing all types of wood. With this revolutionary new development from Format4 you are obtaining all of the advantages of a spiral cutterblock at considerably lower operating, investment and adjustment costs. The advantages of the Silent-Power® cutterblock at a glance ...

- Extremely quiet, noise is reduced by half

- Usable blade life twenty times longer than standard blades

- Four highly precise cutting edges on each knife

- Optimised chip extraction and reduced chip volume

- Tear-free planing results

- Reduced power consumption when compared to similar systems

Technology Data

Electrics

Cutterblock

Thicknesser and Feed Drive

Important Accessories

General

Packaging

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP INDIA Details

India Headquarters | Mumbai Office

Survey Nos. 186D, Shed No. 653, Sasunavghar, National Highway 8,

Vasai Mumbai 401202

Tel.: 1800 274 3040

Business Hours: Monday - Friday | 10am - 7pm (IST)

FELDER GROUP INDIA Details

South Division | Bangalore Showroom

No 387, Ground Floor, 4th Main, 4th Phase , Peenya Industrial Area Phase IV,

Bangalore – 560058

Tel.: +91 80 4157 3661

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

South Division | Chennai Showroom

C/o Don Bosco Technical Campus, No.106, D’Castor Road Basin Bridge,

Chennai – 600012

Tel.: +91 84 3159 5858

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

North Division | Experience Center

A-13, Sector 67,

Noida - 201309

Tel.: +91 120 4554 344

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

West Division | Satellite Service Office

Tel.: Ahmedabad: +91 88 2832 4433

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

South Division | Satellite Service Office

Tel.: Hyderabad: +91 90 2250 7001

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)

FELDER GROUP INDIA Details

East Division | Satellite Service Office

Tel.: Bhubaneswar: +91 77 1880 0306 | Tel. Guwahati : +91 84528 12225

Business Hours: Monday - Friday | 10am - 7pm (IST) Sat (1st & 5th Saturdays only) | 10am - 7pm (IST)