Planer-Thicknesser dual 51

The NEW Format4 dual 51 – perfect precision at just a touch of a button

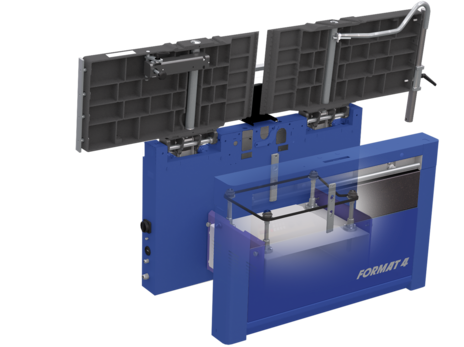

Are you looking for a planer-thicknesser that meets your professional requirements in regards to precision, reliability and ease of use? The Format4 dual 51 sets new standards in all areas. Solid ribbed planing table and a 4 column thicknessing table guide system ensure high stability.

The planer table adjustment system, 120 mm cutting diameter and patented Format4 system cutterblock guarantees perfect planing results. An intuitive operating concept reduces the effort in changing from planing to thicknessing to a minimum, increases the productivity and ensures that the dual 51 is a profitable investment for workshops, businesses and industry.

- Intuitive, synchronised opening of the dual planing table

- The Format4 planing fence: A masterpiece of stability, precision and space saving design

- Highest operational safety, simplest operation: The new Format4 planer guard

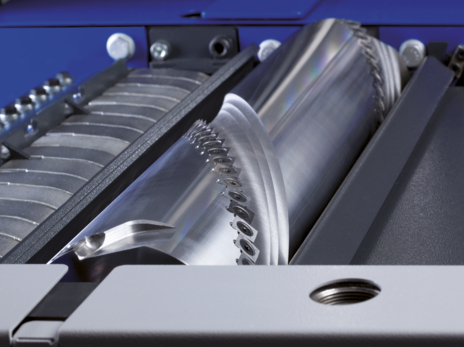

- The Format4 system cutterblock - for many decades a guarantee for excellent planing results

- The innovative Silent-Power® spiral knife cutterblock cuts noise emission by half

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

... FORMAT4 Premium machines for premium requirements

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Tailor made financing solutions

Details

The Silent-Power® spiral knife cutterblock reduces the noise emissions when planing by more than a half. Specially developed tungsten carbide blades with their constant pulling cut, guarantee a tear free planing finish of every wood type. The optimised extraction hood ensures that the noticably shorter chips are effectively extracted and land considerably more compact in the dust bags. This more compact filling of the chip bags, saves you from having to frequently change the bags. Maximum reliability and highest level of planing quality - the innovative new development from Format4 offers a planing system with knives that have a usable life up to 20 times longer when compared to a conventional HSS-blade system. Damaged blades can be exchanged individually, removed and replaced with a few turns of the hand. The advantages at a glance ...

- Sensationally quiet, noise emissions halved

- Blade life up to 20 times longer

- Four highly precise cutting edges on each knife Click here to get more information

For decades the Format4 system with double sided disposable planer knifes proved its advantages. Perfectly manufactured and adjusted in the factory, there is no need to adjust the planer knives, and no expensive adjusting tools have to be purchased.

120 mm cutting diameter and the unique Format4 knife system with reversible blades - for many decades a guarantee for excellent planing results. Maximum blade life and minimum cost of the blades ensure considerable savings.

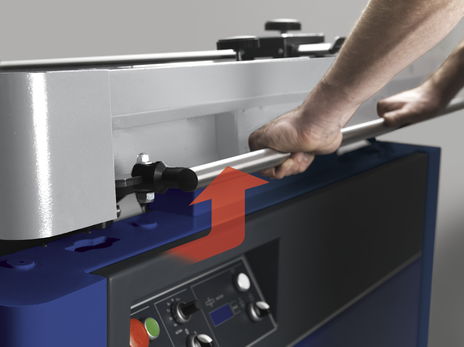

The tried and tested Format4 operating concept reduces the effort in changing from planing to thicknessing to a minimum. The intuitive table clamping system makes it possible to synchronously lock and open the planing tables with a twist of the hand, industrial springs assist in the opening.

A masterpiece of stability, precision and space saving design - the innovative parallelogramm Format4 planing fence system design allows you to be able to position your machine directly next to the workshop wall, without restricting the planing width. The planer fence can be tilted to any position between 90°–45°, the planer fence will always remain flush with the planing table.

Using the tried and tested Format4 table extensions it is quick and easy to extend your thicknessing table by up to 1000 mm without the use of tools.

Technology Data

Electrics

Planer and Cutterblock

Thicknesser and Feed Drive

Important Accessories

General

Packaging

Customer service & maintenance