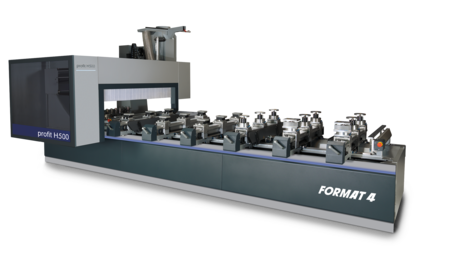

profit H500R

- 5 axes router spindle, solid construction with 12 kW liquid cooled motor

- Drawing = programming, intuitive operating software

- “F4®Integrate” software including 3D cabinet software “F4-Design” for presentation, parts list and connection to the machine

- Possibility of 5 axes processing with “F4 Solid” powered by AlphaCam

- The drilling head covers the whole working field

- High quality dual circuit vacuum clamping system with 100 mm vacuum pod height

- 4 sided door and window processing with automatic delivery, s-motion consoles

- Workpiece thickness up to 250 mm

- F4®Solutionsready