Sliding Table Panel Saw K 945 S

The FELDER top models for the highest demands in craft, trade and industry!

The top panel saw model from Felder impresses with modern design, innovative operating elements, durable precision, extreme performance and maximum operating comfort. The large dimensioned saw unit allows large blade diameters and maximum power transfer at all three speeds. Felder system solutions such as the tilting segment guide ”Easy-Glide“ and the ”X-Roll“ sliding table with 10 year guarantee, ensure reliability for years to come.

The premium Felder sliding table panel saw K 945 S is also available with the revolutionary safety device PCS®.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

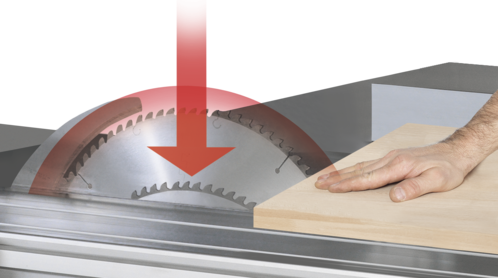

Serious accidents on the sliding table panel saws are a thing of the past - PCS® is currently the fastest non-contact triggering safety device, worldwide.

- PCS detects accident hazards before contact with the saw blade.

- PCS eliminates the hazardous situation in milliseconds.

- PCS is 100% safe against damage to machine and saw blade.

- PCS allows safe operation close to the saw blade.

- PCS supports groove cuts.

- PCS is ready to be used again at the push of a button.

- PCS requires no additional maintenance and cleaning cycles.

- PCS works without additional external energy sources and without external sensors or video systems.

- PCS is resistant to dust and dirt.

*PCS® does not replace any of the legal protective devices required. The machine must be operated with the splitter and the saw guard properly installed according to regulations.

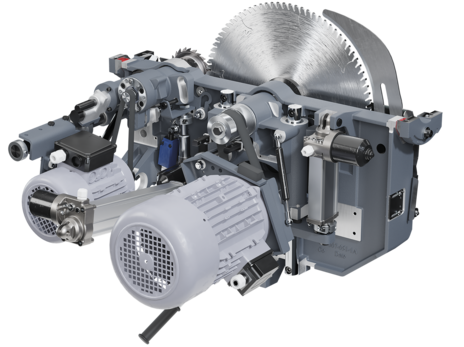

The time-tested, cast iron Felder TOP unit offers not only maximum power and precision, but also extreme smooth running and efficiency:

» 155 mm cutting height with a 450 mm saw blade diameter

» S ensational: saw blade change without tools

» Electrical height adjustment

» Optional: Electronic angle adjustment with digital LED display

» Maximum power transmission achieved through the Poly-V belts and

counter surface

» T ilt segment “Easy-Glide” for circular saw unit

» Absolute vibration-free machining

» Incredible power transmission due to the ultra effi cient Poly-V-belt drive technology

» Standard: Speeds 3500/4500/5500 rpm; with 10 kW motor power speeds of 3500 and 4500 rpm are possible

The clamping system is maintenance free and offers premium comfort for many years: Change saw blades and riving knives effortlessly and literally in the blink of an eye.

Quick and easy blade change with only one tool, thanks to the “Quick-Lock” system.

109 mm cutting height at 45° blade tilt; depending on the set mitre angle, the „Power-Drive“ display compensates for the cutting height and shows the ACTUAL height of cut.

With the “Power-Drive” package you will be able to accurately set both the height and angle of the blade electronically with a turn of a control switch. The saw blade height and angle positions are clearly shown on the LED display screens. When the saw blade is tilted the blade height is automatically adjusted and the new height measurement is instantly updated.

Choose between – two types of absolutely powerful scoring units:

» “Classic” with a scoring blade Ø 120 mm

» “Automatic” with automatic raising and lowering

All units combine tried and tested operation with drive technologies for perfect scoring results. Guaranteed by the scoring saw blade diameter of 120 mm and the speed of 8600 rpm (10,200 rpm at 60 Hz).

A red LED strip immediately signals the operation of the scoring unit and offers even more working safety. (Option)

For the machining of non-ferrous metals or plastics, your machine can be equipped with a spraying unit. High performance lubricating oil can be sprayed directly onto the saw blade, transported via piping from the spraying unit.

Thanks to the removable circular saw flange and table insert, adjustable dado tools up to 19.5 mm can be used.

The newly developed overhead saw guard and under table extraction system deliver perfect extraction results. The overhead saw guard

with its distinctive design is easily adjustable in height over linear guides. The dust and shavings are sucked from the saw guard into the extraction pipe via a short hose. The below table extraction system encloses the entire saw unit. In terms of extraction technology, the chip duct is perfectly shaped, and an optimised chip fl ow from the scoring unit also ensures absolutely perfect extraction results.

The maintenance free linear laser is mounted to the overhead saw guard and can be adjusted to any position. The easily visible cutting marker makes it easier to trim or cut along cracked wood.

On request, we will equip your machine with the digital telescopic fence. Below, you see the cleverly integrated electronic digital scale with values correct to 0.1 millimeter. Additional functions, for example the setting of successive measurements, make your daily working life easier.

This is why:

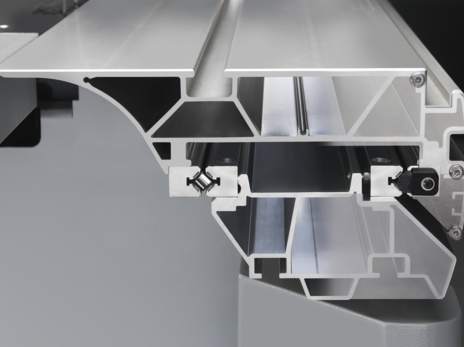

» Long lasting table guides with Felder linear guidance system. No single point contact thanks to roller bearings!

» Clean and dust-free guides due to special wipers.

» Smooth and precise run due to hardened and ground guidings.

» 10 year guarantee.

The outrigger crosscut fence allows you to perform crosscuts up to 2600 mm (optional 3200 mm). Even the standard version already provides you with top-class technology and comfort. The scale that is tilted towards the operator and the lens on the crosscut fence guarantee precise settings.

No time wasted trying to find the correct angle and one hundred percent precision in adjustment and positioning, without any reading errors, are just some of the advantages of the precision mitre index system. High-precision rest points allow the dimensionally accurate Creation of polygons such as 5.625° (32 corner), 11.25° (16 corner), 22.5° (octagon). Additional rest points at 15°, 20°, 25°, 30°, 35°, 40° and 45° can be selected as well as push and thrust. Each resting point is equipped with a length compensation. The high-precision degree raster index System is set at the factory and each resting point can be individually be fine-tuned. That shapely adapted to the machine design degree grid index system boosts your productivity into a unique price-performance ratio.

The crosscut fence is adjusted for mitre cuts between +45° and -45° using the mitre index scale integrated in the format sliding table. The T-slot and lateral holders on the format sliding table allow for quick assembly without tools. The scale facing the operator and the read-out lens on the fence stop ensure precise settings up to 1100/2050 mm.

» Easy clamping of workpieces with maximum flexibility. Can be used on all panel saws and spindle moulders that are equipped with a sliding table.

» Easy set up due to magnetic fittings

» Safety cylinder ensures maximum working security

» Pressure bar function is possible with every sliding table length

» Clamping height 95 mm

» Clamping force approx. 300 kg

Technology Data

Electrical setup

Control Systems

Saw and Scoring Unit

Safety devices

Cutting width and rip fence

Sliding Tables

Outrigger Tables and Crosscut Fences

General

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP UK Ltd. Details

Unit 2 Sovereign Business Park, Joplin Court, Crown Hill

MK8 0JP MILTON KEYNES

Tel.: 01908 635000

Business Hours Monday to Friday 09.00 to 17.00

Felder Group Scotland Details

Unit 4 Lindsay Square, Deans Industrial Estate

EH54 8RL Livingston

Tel.: 01506 342250

Business Hours please call for an appointment