Saw/Spindle Moulder KF 500 professional

Felder quality with every cut

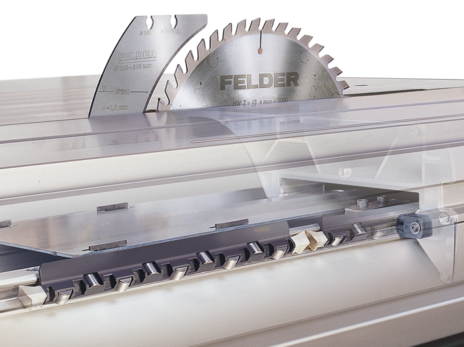

The KF 500 is an inexpensive saw for professional woodworking. The tiltable saw blade, precise professional rip fence, the patented “X-Roll” aluminium sliding table with a 10 year factory guarantee and the tried and tested 500 cutting unit ensure reliability, stability and excellent results. With the 2050 mm sliding table and the 1100 mm outrigger table in this professional package, the KF 500 is a top quality machine.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Variants

Models- Your benefits

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

KF 500 professional

KF 500

As soon as you begin working on your machine, you’ll see that your Felder’s range of applications is much wider than you might have expected and you save a lot on tools too. Using the hand wheel, the moulder spindle unit can Be tilted to the requested angle easily and smoothly to the back.

Technology Data

Electrical setup

Saw and Scoring Unit

Spindle Moulder Unit and Spindle Fence

Sliding Tables

Outrigger Tables and Crosscut Fences

General

Important Accessories

Transport

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP UK Ltd. Details

Unit 2 Sovereign Business Park, Joplin Court, Crown Hill

MK8 0JP MILTON KEYNES

Tel.: 01908 635000

Business Hours Monday to Friday 09.00 to 17.00

Felder Group Scotland Details

Unit 4 Lindsay Square, Deans Industrial Estate

EH54 8RL Livingston

Tel.: 01506 342250

Business Hours please call for an appointment