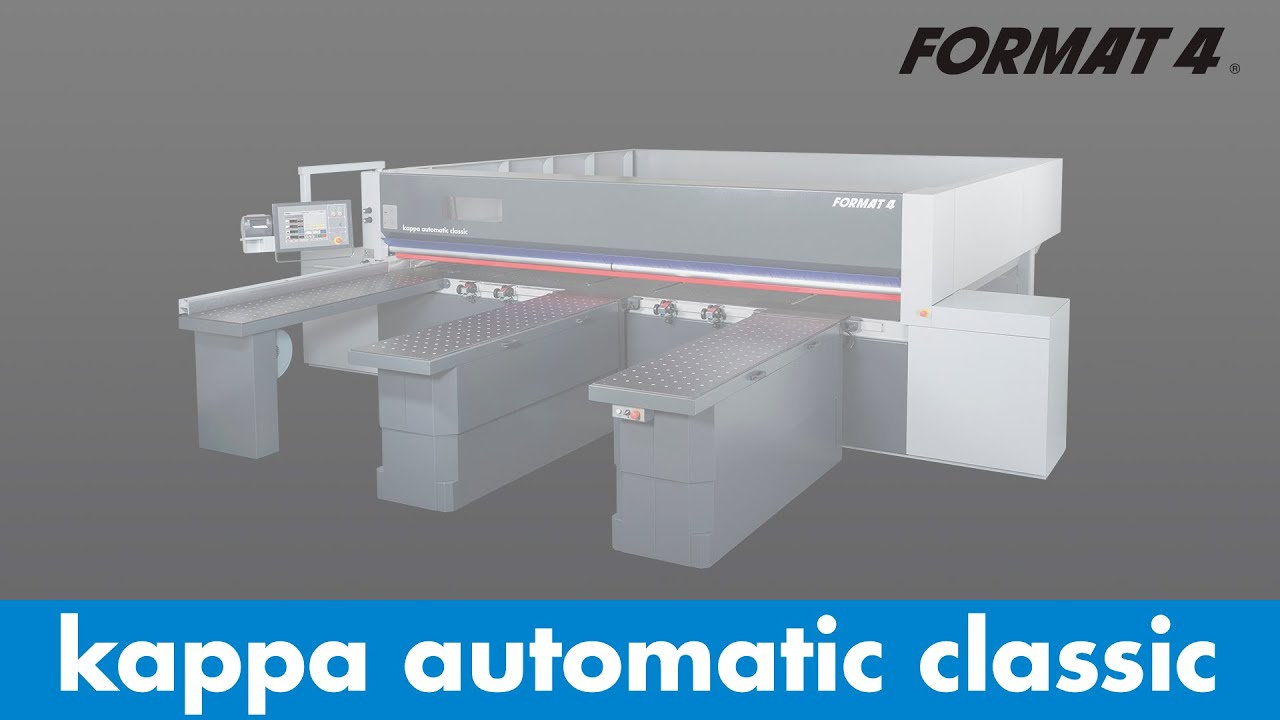

Pressure beam saw | Beam saw, horizontal kappa automatic classic

The compact beam saw for efficient cutting

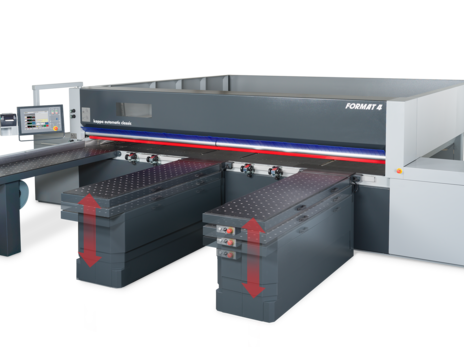

The FORMAT4 kappa automatic beam saw fulfils the individual requirements of the discerning woodworker with efficient panel sizing with an excellent price/performance ratio, with a 2m² less space requirement than saws with the same cutting length.

The classic model convinces with the generous basic specification, with cutting lengths of 3,200 mm and 4,300 mm, two moveable support tables with air cushion function and a pressure device for an exact right angle cut when crosscutting. For perfect, chip free results, the main saw aggregate is equipped with a 7.5kW motor, has a max. 320 mm saw blade diameter and 68 mm saw blade projection. The intuitive touchscreen control concept ensures a quick and simple control of the machine.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

... FORMAT4 Premium machines for premium requirements

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

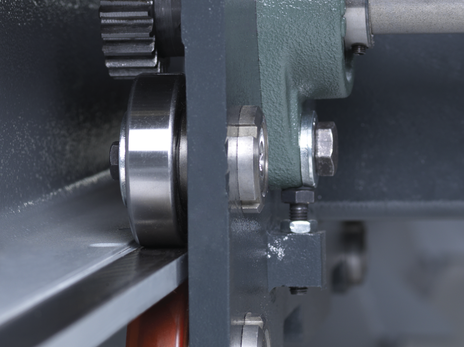

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Automation solutions

- Software and machines from a single supplier

- Tailor made financing solutions

Details

Three separate fans are used for the air cushion function on the side tables. Individual control ensures convenient panel handling and resource-saving use at all times.

Thanks to the flexible operating terminal and the easy-to-see window on the pressure bar, you have always everything important in sight.

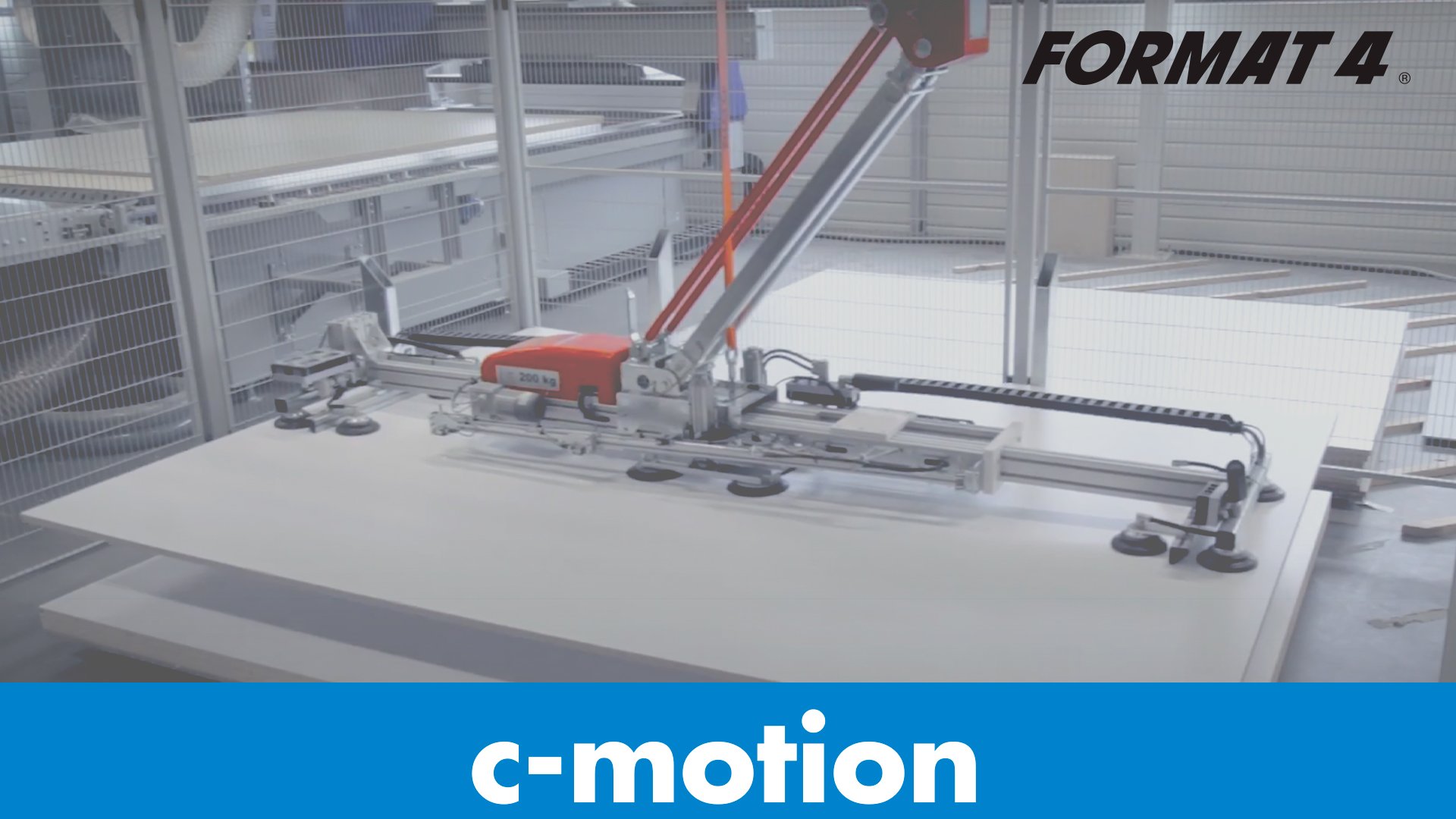

The move towards automation with automatic front lifting tables. Stacks of panels with up to 240 millimetres can be temporarily stored here and processed one plan at a time. In addition, it is possible to load a pre-commissioned panel stack and complete separate cutting plans with minimal set-up time. Here, the thickness of the panel is independent.

With the additional operating terminal on the air cushion table, you save time and increase productivity.

With the material pusher towards the cutting axis, panels can always be loaded reliably and without damage, regardless of the thickness of the material.

To take a further step towards automation, the kappa automatic classic can be equipped with the new, innovative front lifting table system. The standard side tables are replaced by solid, fully automatically controlled scissor lifting tables. This guarantees an enormous increase in efficiency and greatly enhances operating comfort.

The Format4 kappa automatic beam saw, guarantees simple operation and maximum efficiency with numerous software packages.

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP UK Ltd. Details

Unit 2 Sovereign Business Park, Joplin Court, Crown Hill

MK8 0JP MILTON KEYNES

Tel.: 01908 635000

Business Hours Monday to Friday 09.00 to 17.00

Felder Group Scotland Details

Unit 4 Lindsay Square, Deans Industrial Estate

EH54 8RL Livingston

Tel.: 01506 342250

Business Hours please call for an appointment