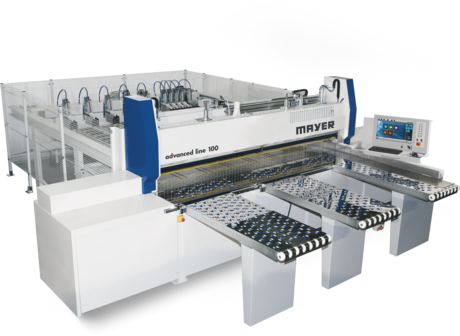

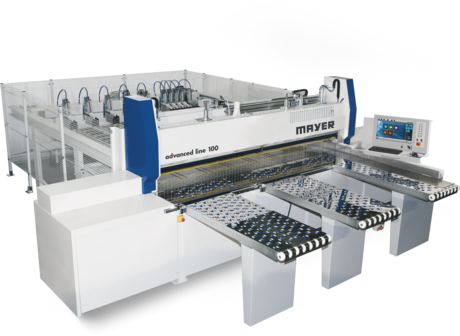

Panel Saw advanced line 100

Beam saws to process aluminium, non-ferrous metals and plastics.

The range of board materials available on the market today is enormous. In addition to processing aluminium and wood, we develop and produce specially configured machines for cutting plastics.

Perfection is in the detail. For our machine concepts, we have therefore developed numerous detailed solutions that capture every challenge exactly in a nutshell. Whether cutting hard or soft board materials, honeycomb and lightweight construction materials, rolled or cast aluminium panels - we find exactly the right solution for our customers. Even for shaped tubes or round bars, we guarantee to have the right product.

Thanks to the solid construction and the powerful saw carriage, the cutting forces are transmitted vibration-free and with the powerful saw motor, our beam saws process aluminium, non-ferrous metals and plastics with high precision and cutting quality. With saw motors of up to 75 kW power, our machines achieve exceptional feed rates and cutting performance in every application.

- advanced line 100. The classic – The result of decades of experience.

- advanced line 130. The experienced – Tailored exactly to customer needs.

- advanced line 160. The Universal – Several times awarded.

- advanced line 160 turn. The comfortable – User-friendly material handling.

- advanced line 200. The massive - For exceptional challenges.

- advanced line 250. The strong – The strongest in its class.

MAYER. Technically perfect, precise and durable

The Otto Mayer machine factory has been producing panel-sizing and pressure beam saws for processing panel materials made of wood, plastics, non-ferrous metals and basic materials since 1950. The many years of experience guarantee quality and reliability at the highest level.

The most important highlights at a glance

Variants

Models- Your benefits

A Mayer beam saw for every challenge

- The advanced line 100 is the result of decades of experience in the field of aluminium cutting and convinces with a very stable construction as well as highest precision and cutting accuracy. A safe investment in the future.

- Each market and customer has his own special demands when it comes to panel cutting. According to these requirements, the advanced line 130 combines the extraordinary with the useful.

- The advanced line 160 - The top seller under the beam saws for aluminium with several awards for innovative solutions and patents.

- The advanced line 160 turn offers comfortable operation for easy material handling, even with heavy components.

- The advanced line 200 - The compact beam saw for maximum load and extraordinary challenges.

- The advanced line 250 is the strongest beam saw in its class. Maximum performance with outstanding precision and cutting quality convince in every challenge.

Details

The split pressure beam facilitates minimum trimming cuts (chip or scratch cuts) regardless of the programmed board dimension. This guarantees optimal material utilisation with perfect dust extraction.

Through optimised traverse paths of the saw unit with rapid traverse shutdown. The saw unit moves at high speed until just before the material to be cut and then automatically switches to the set feed speed.

Power-saving transportation of heavy panels for highly productive one-man operation is possible thanks to the universal roller tables that are moved on linear guides.

Thanks to the pneumatic liftable table segments, heavy panels can be moved easily and without beeing damaged.

The riving knife for panels with high material tensions is mounted at the end of the saw carriage and can be mechanically connected and disconnected.

Two independent servomotors with separate measuring systems and programmable correction curves guarantee absolute precision for all travel distances.

Quickly and easily change the position of the front desk by 90 degrees and thus have a space-saving or large-sized supporting surface.

The pneumatic pressure rollers inside the rear machine table and behind the pressure beam guarantee exact 90-degree angles.

An accurate sensor for saw blade deviation ensures material-saving cuts and also reduces the costs for saw blades.

Special sound insulation systems ensure the lowest possible energy consumption. Engines that are not needed turn off automatically and dust extraction happens only where chips are really produced.

Additional tables can be moved easily and precisely on the ground linear guides.

advanced line 100

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

advanced line 130

Automatic length measurement system for trimming cuts.

Ergonomically arranged controls on the side table.

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

advanced line 160

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

advanced line 200

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

advanced line 250

The lamella screen seals the area around the cutting axis, thus improving the extraction performance and preventing the spread of chips. This is especially essential when machining plastics and aluminium.

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP UK Ltd. Details

Unit 2 Sovereign Business Park, Joplin Court, Crown Hill

MK8 0JP MILTON KEYNES

Tel.: 01908 635000

Business Hours Monday to Friday 09.00 to 17.00

Felder Group Scotland Details

Unit 4 Lindsay Square, Deans Industrial Estate

EH54 8RL Livingston

Tel.: 01506 342250

Business Hours please call for an appointment