Clean Air Dust Extractor RL 350 | Ø 350 mm

Clean-air dust extractors for professional use.

It is clear that wood dust accumulates in workshops and it is also widely known that this dust has been classified as a health hazard for some time, but it is only recently that the topic of dust extraction in this industry has become a real talking point. An EU regulation soon to come into force will allow companies that have an air filtering requirement of up to 8,000 m³/h (previously 6,000 m³/h) to use wood-dust-approved clean-air dust extractors, saving them from the expensive investment of an externally positioned extractor. However, in addition to the numerous rules and regulations, one thing is also absolutely clear: Dust-free working is not only healthier, but also offers numerous opportunities for energy and cost savings in wood processing workshops. An individually adapted extraction solution is simply essential for a healthy workshop.

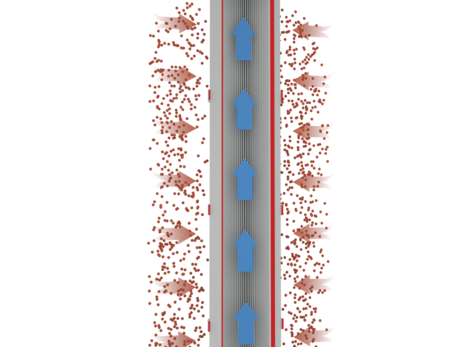

Felder offers air filters, clean-air dust extractors and filtration systems for efficient chip extraction and air cleaning. All models achieve a remaining dust concentration level of less than 0.1 mg/m³, in accordance with remaining dust content level H3. Unlike conventional dust extractors, Felder positions the ventilator behind the filters. This generates a negative pressure throughout the entire system, preventing dust escaping through any leaks.

FELDER. Quality and precision in a nutshell

Since 1956, a guarantee for perfect results with excellent ease of use and reliability in regular professional use. Woodworkers are always enthusiastic about the individual and solid solutions for small and mid-sized businesses.

The most important highlights at a glance

Variants

Models- Your benefits

... Your decision for Felder, a risk-free decision

- The right machine for every budget

- Complete reliability in professional use

- Tailor made machine solutions

- High quality cast iron machine table and aggregates

- Innovative detail solutions derived from 60 years of experience – already included in the standard configuration

- First class manufacturing and finishing standards

- Intuitive application concepts

- Modern, distinct design

- Quality and precision from Austria

- Powerful and efficient

- Complete package: Comprehensive service support

Details

The chip collection bins are positioned under the machine ensuring an optimised filling of the dust bags. The optimised clamping system ensures a quick dust bag changeover.

--- Large filter area with small space requirement

--- Reduced load on the filters

--- Maximum filter durability

Continuous automatic blasts of compressed air clean the filter completely and guarantee long lasting perfect extraction results.

High standards: Water fire extinguisher and pneumatic filter cleaning. Optional: Powder fire extinguisher

Equipped with a rotary feeder instead of chip collection boxes

Fuel, disposal costs or storage space are all becoming more and more expensive. The Felder briquetting presses reduce the volume of waste by 90 % and additionally eliminate the need for investment in a chip container or silo. Felder briquetting machines are suitable for continuous use due to their design. They are assembled on a solid base frame and can be combined to use with clean air dust extractors by Felder.

Technology Data

Electrical setup

Wood chip briquetting press

General

Automatic Start

Important Accessories

Customer service & maintenance

Do you have any questions?

Showrooms

FELDER GROUP UK Ltd. Details

Unit 2 Sovereign Business Park, Joplin Court, Crown Hill

MK8 0JP MILTON KEYNES

Tel.: 01908 635000

Business Hours Monday to Friday 09.00 to 17.00

Felder Group Scotland Details

Unit 4 Lindsay Square, Deans Industrial Estate

EH54 8RL Livingston

Tel.: 01506 342250

Business Hours please call for an appointment