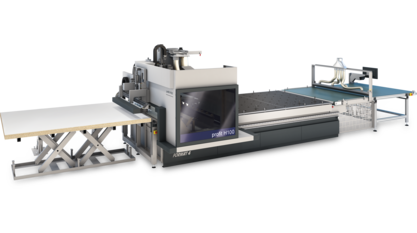

Nesting CNC Machining Center profit H100

The new Nesting CNC Machining Centre FORMAT4 profit H100

The panel cutting, drilling and milling centre for future-proof carpentry and joiner's workshops. Entire custom-made furniture with all holes, grooves and connections are produced in one single operation. The latest nesting technologies ensure the highest possible material and time savings. The profit H100 can be extended to full automation with different loading and unloading solutions, thus achieving maximum productivity.

Four sizes (16.38, 22.32, 22.43 & 22.61) are available with integrated SMART ZONING vacuum management, high-end automation levels, above-average drill heads, new safety concepts and much more. For the unrestricted use of the spindle, a recessed series of fence rows is available. A large Z passage size of 200 mm offers flexible machining of high workpieces.

With the standard tool changer and optionally available moving rotary tool changer as well as the pick-up space for a large saw blade, a total number of up to 35 tool places are available. The automatic pre-labelling on the loading table minimizes sources of error and at the same time reduces the processing times.

With the performance package, the CNC control makes the highest industry standard possible. Different optimisation levels ensure shorter process times, different milling results and increased comfort in CNC machining.

FORMAT4. Uncompromising expertise for the highest of requirements

The Felder Group premium brand has met the highest standards of professional users since 2001. The customised high-performance solutions are uncompromisingly innovative, offer maximum operating comfort and complete productivity.

The most important highlights at a glance

... FORMAT4 Premium machines for premium requirements

- Tailor made financing solutions

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Automation solutions

- Networked workshop

- Software and machines from a single supplier

Details

For the highest demands, all inclusive - tool library, programming section and an operator control panel on the machine with a consistent and intuitive user interface. F4®Integrate is a software developed by Format4® Developed from practical experience for practical use in cooperation with our CNC customers, F4®Integrate meets the highest demands in modern CNC machining.

Enjoy the comfort of a state-of-the-art and well-coordinated user interface. Tool library (F4Toolbox), programming section (CAM area with integrated CAD area, F4Create) and machine operation control (F4Operate) all packed into just one single screen, with a consistent and intuitive user interface.

F4Integrate is based on G-Code, so external industry programs can be easily connected and the transfer of programs smoothly organised.

With a motor power of 10, 12 or 15 kW (depending on the series) and up to 24,000 rpm, the milling motor is controlled using an inverter and is attached directly to the support module of the drilling head in the Z axis. Dual linear guides guarantee highly precise vertical guiding. The main motor is positioned using ground ball screws. The HSK F63 tool clamping is done automatically. The clamping of the tool is checked using sensors, which then confirm that it is safe to start the operation. The tool holder is cleaned pneumatically. The C-axis is available as the fourth axis and is interpolating (360°) with a compressed air interface for aggregates as standard.

Regardless whether the machine will only be used for cabinet manufacturing or as an all-rounder, you can decide which drilling head configuration is the right one for you. Choose between, a drilling head with only vertical spindles or one with spindles and a grooving saw for vertical and horizontal processing. Inverter controlled motor up to 7,500 rpm

The C-axis is optionally available as fourth interpolating (360°) axis and has a compressed air interface for aggregates.

Smart Zoning allows fast processing of several common panel formats. The rapid change from one panel format to the next increases productivity.

The extraction bell optimises the suction results and reduces the required extraction volume due to its compact design.

All across the piece of furniture, F4®Solutions generates a consistent, efficient and profitable production process. The software tools for maximum productivity accompany you through the entire production chain. Easiest design of individual pieces of furniture in the familiar CAD environment. Photorealistic rendering of sales assisting 3D visualizations. Detailed data transfer to all integrated machines with economic nesting optimization. Even the final assembly is accompanied by clear, detailed drawings and 3D data - that's 4.0 for trade and industry. In our videos you will learn everything about Craft 4.0 and Industry 4.0.

The upper table extraction on the conveyor belt cleans the workpieces on the surface during transport. This guarantees that the labels will remain in place on the dust free surface.

Final chips are completely extracted by the under-table extraction between conveyor belt and worktable.

The labeling system facilitates the work steps and guarantees absolute process reliability. The automatic pre-labelling on the loading table minimizes sources of error and at the same time reduces the processing times.

The CNC machining centre can be extended to full automation with different loading and unloading solutions, thus achieving maximum productivity.

For quick access to change the drill or maintenance work, the hood can be easily opened on all CNC machining centres.

The cover optimally protects the high-precision HSK tool adaptors from dust and/or chips. Uneven running of the spindle due to dirt can therefore be excluded.

With the performance package, the CNC control makes the highest industry standard possible. Different optimisation levels ensure shorter process times, different milling results and increased comfort in CNC machining.

- Increase of the maximum axis speeds by up to 30% in the X and Y directions.

- Optimisation of positioning and rotation speeds by up to 80%

- "Multitouch" function on the control terminal for user-friendly CNC machine operation

- Smooth, consistent and steady tool movements for best surface results on the finished workpiece.

- Reduced vibration behaviour during CNC machining via the built-in jerk control

The automatic labelling unit places the component labels in the correct position even before processing.

This reduces sources of error and eliminates the need for additional work for the machine operator once processing has been completed.

If the hood is in parking position, the entire working area is freely accessible. The machine operator therefore has no operational restrictions during workpiece positioning.

Thanks to its small footprint, the short out-feed table simplifies the removal of workpieces. An optional labelling unit can then be used to label the workpieces directly at the point of removal so that they can be identified in subsequent production processes.

![P_D_F4_profitH80_Entnahmetisch_01[1].jpg](/WEB/FelderGroup/Machines/Details/image-thumb__94818__fgroup-product-detail-details/P_D_F4_profitH80_Entnahmetisch_01%5B1%5D~-~media--3875e560--query.jpg)

Customer service & maintenance

Do you have any questions?

Showrooms

Vishering Trade Eurl Details

Addis Abeba/ Nairobi

+251 984 79 66 70 Addis Abeba +254 748 71 72 32 Nairobi