Plastics and composites

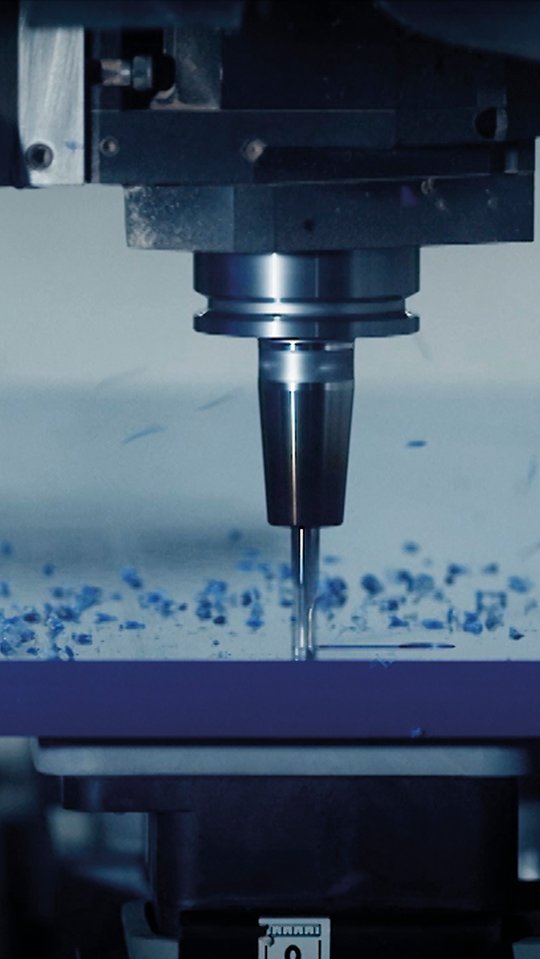

The machining of plastics & composite materials requires specially adapted and equipped machines.

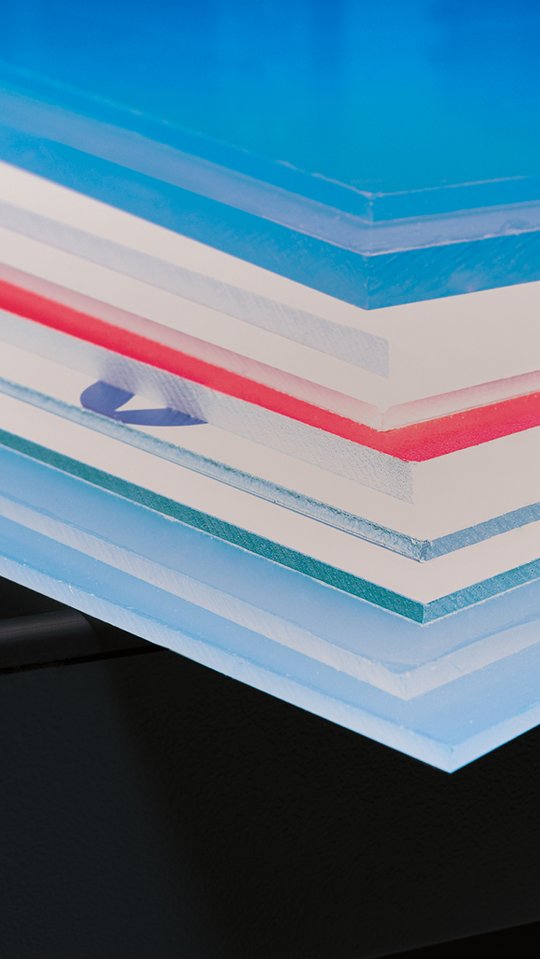

Every year, new plastic compounds are produced, resulting in new semi-finished products, various non-ferrous metal alloys and new Composite materials.

Processing of plastic and composite materials.

Plastics are mainly used when the relationship between weight and strength of the material is important.

A wide variety of components are produced from plastics by machining. The special characteristics of the materials must be taken into account. Above all, it is the relatively low heat resistance that plays a major role during processing. Excessive heat development can lead to distortion or breakage and possibly cause the component to expand. Therefore, sufficient heat dissipation must be ensured.

Machines and tools for plastics processing.

Carbide tipped saw blades are ideal for cutting plastics with the circular saw. When cutting panel materials, it is important to pay attention to use a sufficiently high feed rate. Furthermore, a sufficient offset (the deflection of the teeth to the left and right) is recommended. This ensures good chip removal, prevents jamming of the saw blade and counteracts overheating.

Band saws are particularly suitable for cutting round or hollow bars and are versatile for straight, continuous or irregular cuts. The long saw blade on band saws is particularly effective at dissipating the generated heat.

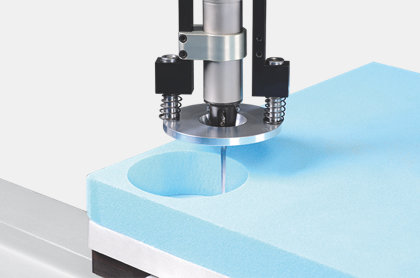

When moulding plastics, it is important to use tools with a sufficiently large chip space. The larger chip space ensures reliable chip removal and heat build-up is avoided. Best milling results are achieved with up-cut milling and surface milling with low rake angle.

To avoid the risk of chipping, tearing, overheating or dimensional deviations when drilling into plastic parts, it is primarily important to use well-sharpened bits. Furthermore, no excessive pressure should be applied and by frequently pulling out the bit additional cooling should be ensured.